First of all, the range of materials that waterjet cutting machine can cut can be said to be very, very wide, including metal, stone, glass, ceramics, plastics, and even the cutting of automotive interiors and exteriors that can be seen everywhere in our daily life. Appear. So if we want to cut materials, how should we choose the cutting tools on the market?

The common cutting tools on the market can basically be summarized into four categories. Waterjet cutting, laser cutting, plasma cutting and flame cutting, these cutting methods are cutting tools that our water jet cutting users will also use. The most common one is laser cutting, but in fact they all have their own advantages and disadvantages. When selecting cutting tools, we should consider factors such as material properties, thickness, shape, precision requirements, cutting speed and cost, etc. Considering. The following are some simple comparisons of these types of tools, which can be used as a reference for everyone to purchase machines:

Waterjet cutting machine

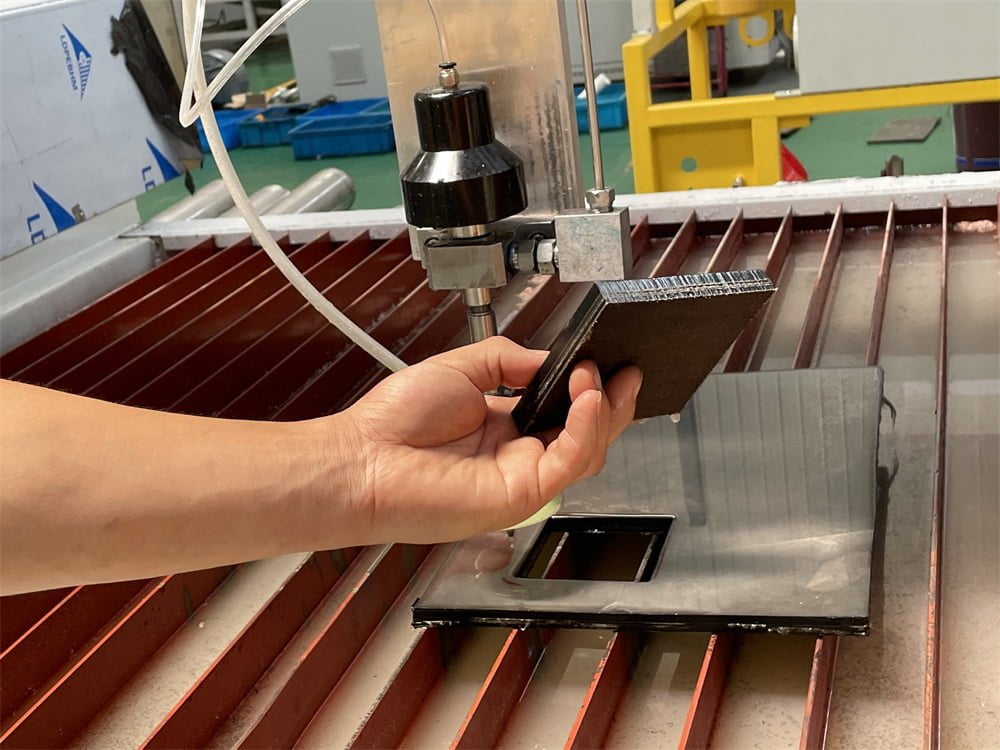

1. Waterjet cutting machine, as the name implies, is the technology of cutting with high-pressure water jet. The water jet can be used to cut any material in a cold state without thermal deformation and heat-affected zone. It has high cutting precision, narrow kerf and good surface quality. No secondary processing work is required. However, compared with the other cutting methods mentioned here, water cutting also has its disadvantages, that is, its cutting speed is very slow, and the cost of equipment and maintenance costs are not low. Maintenance work is required to keep the equipment functioning properly.

Laser cutting machine

2. Laser cutting is to use a focused high-power-density laser beam to irradiate the workpiece, so that the irradiated material is rapidly melted, vaporized, burned or reached the ignition point of the workpiece, and at the same time, the molten material is blown away with the help of high-speed airflow. The effect of cutting the workpiece. Laser cutting machines have a wide range of applications. Both metal and non-metal can be cut with laser equipment, and the cutting speed of laser cutting machines is very fast, with high precision and small plate deformation. However, laser cutting also has disadvantages. For example, the investment cost of laser equipment is high, and the maintenance cost is also high. Moreover, the cutting effect of some thick plates is not good, the surface roughness is poor, and a certain heat-affected zone and gas will be generated pollution.

3. Plasma cutting, this cutting method is a processing method that uses the heat of the high-temperature plasma arc to partially melt (and evaporate) the metal from the incision of the workpiece, and uses the momentum of the high-speed plasma to exclude the molten metal to form an incision. Plasma cutting is suitable for cutting various metal materials such as stainless steel, aluminum, copper, cast iron, carbon steel, etc., especially for thick plates with better cutting effect and high cutting efficiency. However, plasma cutting also has disadvantages. For example, the precision of cutting with this tool is very low, the slit is wide, the end face has a slope, the cost of use is high, and it will produce obvious thermal effects and noise pollution.

4. Flame cutting is to use the flame generated by the mixture of oxygen and acetylene (or other combustible gases) to heat the workpiece, and after it reaches the ignition temperature, pure oxygen is injected for oxidation reaction, and a large amount of The heat makes the processed material to be cut continuously along the predetermined trajectory. Flame cutting is suitable for cutting thick plates of easily oxidized materials such as carbon steel and low alloy. The overall cost of the equipment is low and the operation is simple. A large amount of smoke, noise and harmful gas have certain harm to the environment and human body.

5. Another cutting method is wire cutting, but wire cutting can only cut conductive substances, with high precision, but the speed is very slow, and sometimes it needs to use other methods to perforate and wire to cut.

You can see here that the relatively suitable cutting methods among these cutting methods are waterjet cutting machine and laser cutting. Compared with laser cutting, although the speed of waterjet cutting machine is relatively slow, it is limited to relatively thin plates. If it reaches a certain thickness, the laser cannot penetrate the surface of the object, and the application of water jet cutting is more extensive. , so now many people will choose waterjet cutting machine to cut materials.

Among the customers we have served before, some customers have both laser cutting machines and waterjet cutting machine, but because the metal sheets they cut are relatively thick, so after trying out a set of the 3 axis abrasive waterjet cutting machine from us, they subsequently purchased five sets of abrasive waterjet cutting machine, and we plan to purchase another ten sets this year. We have completed the design of the supporting waterjet cutting production line for them according to the customer’s requirements. It is expected to start production in the second half of 2023, and the delivery can be completed before Christmas. Cargo and installation work.

You must be wondering why our waterjet cutting machine users trust us so much and bought so many sets of waterjet cutting machine from Win-Win in just three to five years?

First, we are a professional equipment manufacturer engaged in the water jet cutting industry for more than 20 years. We have our own production plant and R&D team. Oriented development direction, providing customers with customized solutions, helping many customers solve their technical problems.

Second, we have good customer feedback and good reputation in the entire international water jet cutting market. No matter what problems the customer’s machine encounters, we can provide remote or local services to solve the problem for customers in time, so that Customers have no worries.

Third, the products we launch are all designed according to international standards, and our customers can buy corresponding waterjet cutting machine accessories in any local water jet cutting market, and we never bundle our products.

Fourth, our technical team members will go to customers in various countries to conduct return visits to customers every year. If there are problems, they will be solved and given feedback in time. Therefore, many of our customers are recommended by our old customers who have previously made deals. Here we are also very grateful for the trust of these old customers.

1. Have you ever encountered a situation where the waterjet cutting machine pressure is insufficient or the pressure fluctuates?

Answer: 1.1 Insufficient pressure may be due to the filter at the water inlet of the water jet. If it is not clear for a long time, it may be blocked, resulting in poor water flow and insufficient pressure. Therefore, it is necessary to clean and replace the filter regularly to remove impurities and keep the water flowing smoothly.

1.2 The failure of the high-pressure pump or valve of the water jet will also lead to a drop in pressure, which needs to be checked regularly. If it is damaged or aging, it needs to be replaced or repaired in time

1.3 Whether the nozzle of the water jet is worn or blocked, if there is a problem, it needs to be replaced or cleaned in time

2. What should I do if the cutting speed of the waterjet is very slow?

Answer: 2.1 It may be that the water pressure is not high enough, resulting in insufficient kinetic energy of the water jet, resulting in low cutting efficiency; the water pressure can be boosted to improve this situation, but it should be noted that the water pressure cannot exceed the tolerance range of the equipment

2.2 The type of abrasive, particle size and flow rate are not well adjusted, resulting in weak grinding ability of the water jet and low cutting efficiency; choosing the right abrasive will enhance the grinding ability of the water jet and improve cutting efficiency

2.3 The thickness, hardness, toughness, etc. of the cutting material affect the cutting speed. Generally speaking, the thicker, harder, and tougher the material, the slower the cutting speed; the cutting parameters can be optimized, and the cutting can be adjusted according to the thickness, hardness, etc. of the material The height, angle, speed and other parameters of the head enable the water jet to penetrate the material effectively

2.4 The complexity of the cutting shape will also affect the cutting speed. Generally speaking, the more complicated the shape is, the slower the cutting speed will be; the only way to change this situation is to simplify the cutting shape as much as possible, and minimize the turns and corners. , holes and other complex shapes to improve cutting efficiency

3. Some users who use water jet cutting equipment for the first time say that the effect of cutting materials with water jets is not good, what should I do if the cut surface is rough?

3.1 In this case, it may be that the pressure of the waterjet cutting machine is not high enough, resulting in an unsatisfactory cutting effect; the pressure of the waterjet cutting machine can be increased to increase the cutting capacity and speed

3.2 The abrasive quality of the waterjet cutting machine is not good, or the amount of abrasive is not suitable; this requires professional advice from experienced water jet operators

3.3 The nozzle of the waterjet cutting machine is severely worn or the distance between the nozzle and the workpiece is not suitable, resulting in uneven cutting; you need to adjust and try until you find the best distance to ensure uniform and smooth cutting

3.4 The cutting parameters are not adjusted properly, maybe it is caused by the set cutting speed is too fast

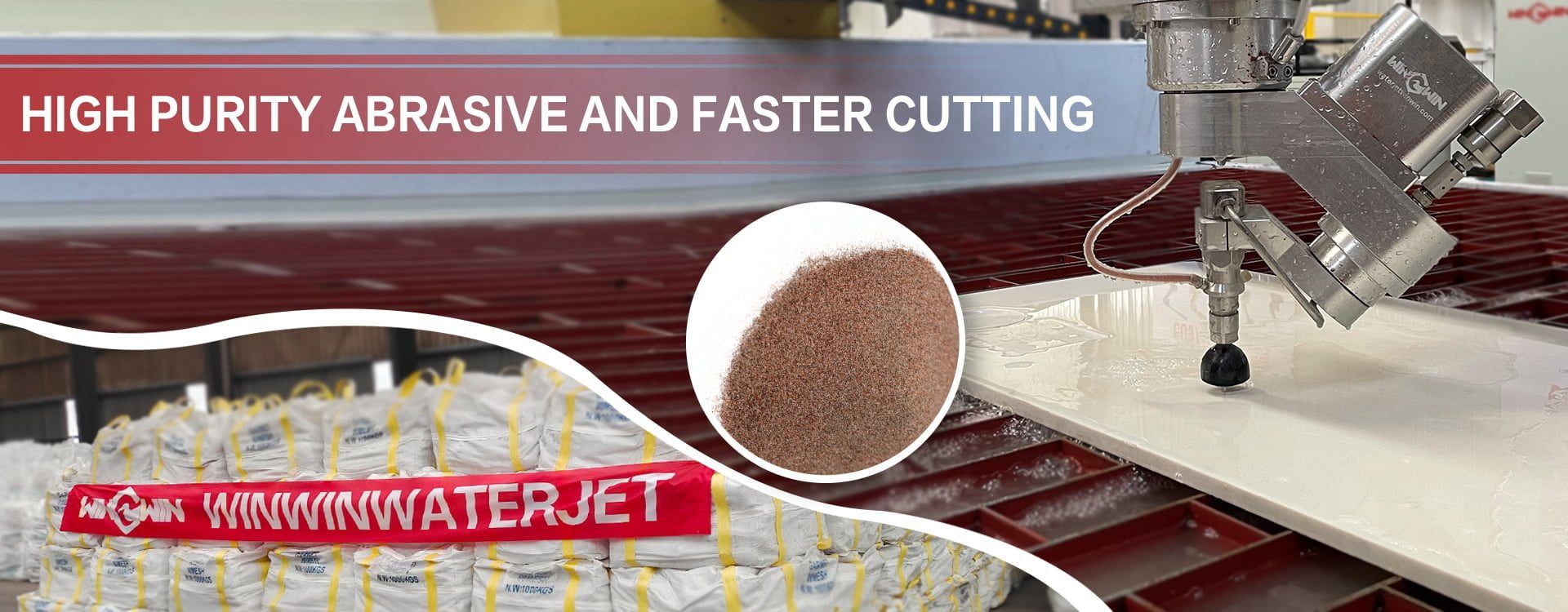

4.How to choose the suitable size of waterjet abrasive garnet?

Choosing the right size of waterjet abrasive garnet mainly depends on the hardness and thickness of the material you want to cut, as well as your requirements for cutting quality and speed. Generally speaking, the larger the particle size of the waterjet abrasive garnet, the faster the cutting speed, but the rougher the cutting surface; on the contrary, the smaller the particle size of the waterjet abrasive garnet, the slower the cutting speed, but the smoother the cutting surface

The particle size range of waterjet abrasive garnet is usually between 50-300 mesh, of which 50-80 mesh is suitable for cutting thicker or harder materials, such as steel, glass, marble, etc.; 80-120 mesh is suitable for cutting medium thickness or Hard materials, such as aluminum, copper, ceramics, etc.; 120-300 mesh is suitable for cutting thin or soft materials, such as rubber, plastic, paper, etc.

Of course, the particle size selection of waterjet abrasive garnet should also take into account the performance and configuration of the waterjet cutting machine, as well as the cost and supply of waterjet abrasive garnet. Generally speaking, the higher the pressure of the waterjet cutting machine, the smaller the particle size of the waterjet abrasive garnet can be; conversely, the lower the pressure of the waterjet cutting machine, the larger the particle size of the waterjet abrasive garnet should be. In addition, the composition and purity of waterjet abrasive garnet will also affect the cutting effect and life. Generally, it is recommended to use waterjet abrasive garnet with no free silicon or less than 1% free silicon.