90,000psi Ultra High Pressure Intensifier Waterjet Pump

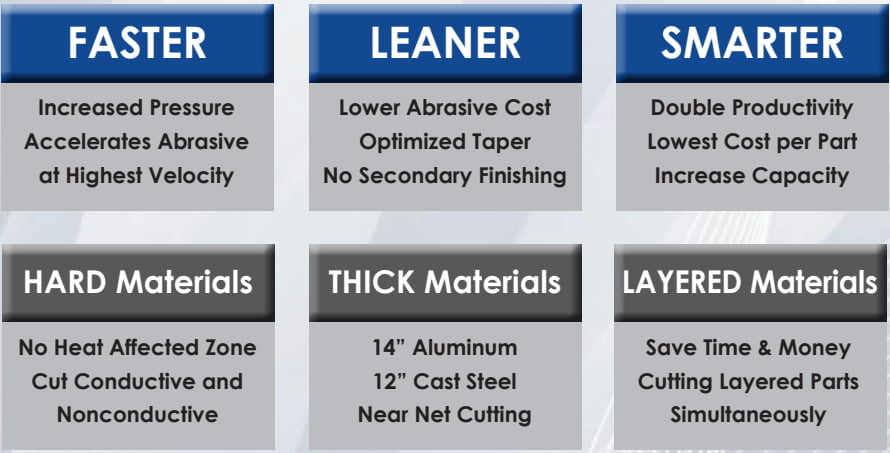

1. Can cut ultra-thick material

2. The thickest metal material can be cut to 300MM

3. The touch screen displays the working status of the core components in real time

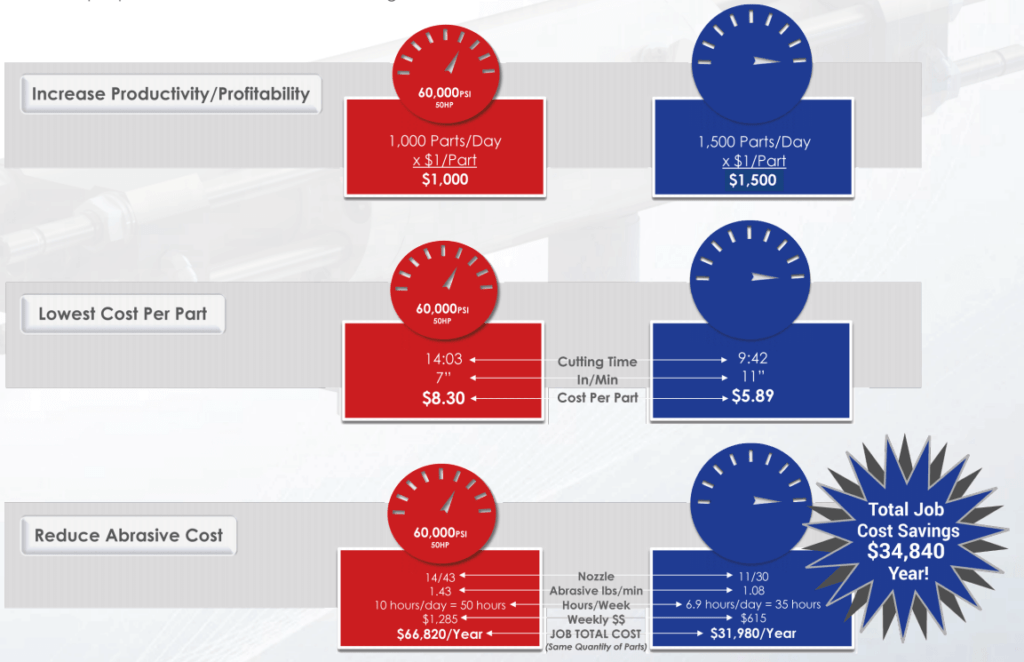

4. The cutting speed is faster compared with the ordinary intensifier pump, the cutting efficiency can be increased by 50% – 70%.

5. Higher production capacity and reduced operating costs

90000psi Waterjet Pump Application:

Many of our aircraft manufacturer customers in the aerospace field use this ultra-high pressure intensifier pump to cut materials. In order to meet the cutting needs of customers, we have gradually improved the product system of intensifier pumps. Regarding this ultra-high pressure intensifier pump, we currently have three types for you to choose from

1. The intensifier pump with single intensifier structure can meet the basic cutting needs, especially for ultra-thick materials and hard alloys.

2. Dual intensifiers’ linkage structure, the design of this structure can reduce the number of mechanical reversing, thereby reducing the number of replacement and maintenance of related wearing parts, and prolonging the use time and service life of related water jet parts

3. Dual intensifiers work alternately, which can realize 24-hour uninterrupted work in a real sense

A waterjet pump operating at 90,000 psi (pounds per square inch) is a powerful tool used in various industrial applications where precise and high-pressure cutting, cleaning, or shaping is required. This technology uses a stream of high-pressure water mixed with abrasive materials (in the case of abrasive waterjet cutting) to perform various tasks. Here are some industries and applications where a 90,000 psi waterjet pump can be used:

Metal Fabrication and Manufacturing:

- Metal Cutting: Waterjet cutting at such high pressures can cut through a wide range of metals, including stainless steel, aluminum, and titanium, with exceptional precision.

- Metal Shaping: It can be used for shaping and contouring metal components.

Aerospace:

- Composite Cutting: Waterjets are used to cut composites like carbon fiber and fiberglass, which are commonly used in the aerospace industry.

- Precision Component Manufacturing: High-pressure waterjets are used to cut intricate and precision parts for aircraft.

Automotive:

- Automotive Parts Manufacturing: Waterjets can cut automotive components with high precision, such as interior and exterior parts, gaskets, and engine components.

Construction and Architecture:

- Stone and Tile Cutting: Waterjets can cut natural stone and tiles for architectural purposes, including intricate designs and mosaics.

- Concrete Cutting: They are used for precise cutting in concrete and construction work.

Glass Industry:

- Glass Cutting: Waterjets can cut glass for various applications, including architectural glass, automotive glass, and artistic glasswork.

Electronics:

- PCB Manufacturing: Waterjets can precisely cut printed circuit boards (PCBs) and electrical components.

Food Processing:

- Food Cutting: In the food industry, waterjets can be used for cutting and portioning various food products, including meats, fruits, and vegetables.

Mining:

- Mineral Extraction: Waterjets can be used for cutting and drilling in mining operations.

Oil and Gas:

- Pipe Cutting: Waterjets can cut through pipes and other materials in the oil and gas industry.

Marine:

- Shipbuilding: Waterjets can be used for cutting and shaping metal components in shipbuilding.

Art and Sculpture:

- Artistic Creations: Artists and sculptors use waterjets for precision cutting and shaping of various materials, including stone, metal, and glass.

Agriculture:

- Agricultural Equipment Manufacturing: Waterjets are used in the manufacturing of specialized agricultural equipment and components.

Defense and Aerospace:

- Military Applications: Waterjets are used in military applications for cutting and shaping materials and components.

These are just a few examples of industries and applications where high-pressure waterjet pumps operating at 90,000 psi can be utilized. The ability to cut a wide range of materials with high precision makes waterjet technology a versatile and valuable tool in various industrial sectors.

Brand | WINWIN | Model | Scremlin Pro |

Name | 90,000psi waterjet pump

| Temperature | 5-40°C |

Pressure Range

| 90,000psi (6.200 bar) | Oil Level and Temperature Control

| Sensor |

Low Pressure Filter | 10 µm abs. | Application | Water jet cutting system

|

Voltage | 380V | Rated power | 60hp (45kw) |

Attenuator capacity | 2L | Nom. Current at 480V/60Hz (Full Load Amp) | 70 A |

Maximum water flow | 0.78 gal/min (2.9 lpm) | Min. Cutting Water Inlet Flow | 4.0 gal (15.1 L)

|

Hydraulic Tank Capacity | 220L | Size (L * w * h) | 2.2m*1.4m*1.5m |

Using hard seal structure, no soft seal wear, greatly prolonging the service life of related wearing parts, reducing the number of maintenance and disassembly

Large-capacity accumulator, reducing water pressure fluctuations, more stable water pressure, smoother cutting surface

The design of the whole set of products conforms to the ergonomic engineering, and the maintenance is convenient

The touch screen displays the working status of the core components of the intensifier in real time, making it easy to find the problem

Ultra-thick metal 300MM

Hard material products, such as cemented carbide, etc.

Fast and efficient, no thermal impact on the cutting surface

Water jet cutting is to raise the pressure of the water flow to a high enough level (200MPA), so that the water flow has great kinetic energy, which can penetrate chemical fibers, leather, rubber, etc., and mix a certain proportion of abrasives in the high-speed water flow, it can penetrate almost All hard materials such as ceramics, stone, glass, metals, alloys, etc. Under the guidance of the CNC processing platform, the processing can be started or finished at any position of the material, and the plane cutting processing of any graphics can be realized according to the set trajectory at an appropriate moving speed.

The advantages of cutting with water jet machines are:

Can easily cut stainless steel plate or hard marble, granite, etc.

For composite materials that are difficult to cut by other methods, such as titanium alloys, it is the only processing method

Cold cut form, no thermal deformation, no secondary processing

There is no restriction on the cutting direction, and various special-shaped processing can be completed

We have a variety of waterjet pump models for you to choose from

WWJET50 Pump: This is a basic waterjet pump with a maximum working pressure of 420MPA and a continuous working pressure of around 360-380MPA.