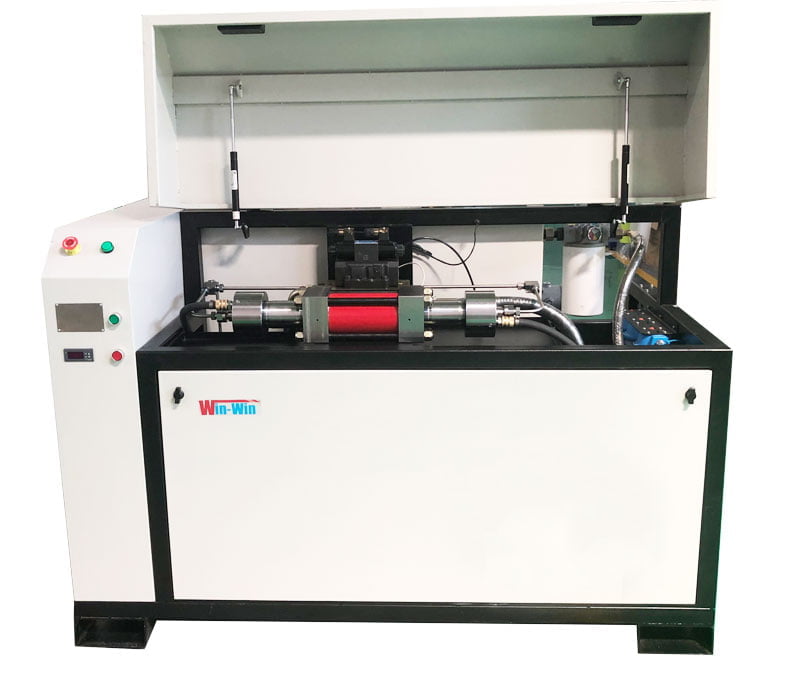

3 axis waterjet cutting machine with ground available lifting system

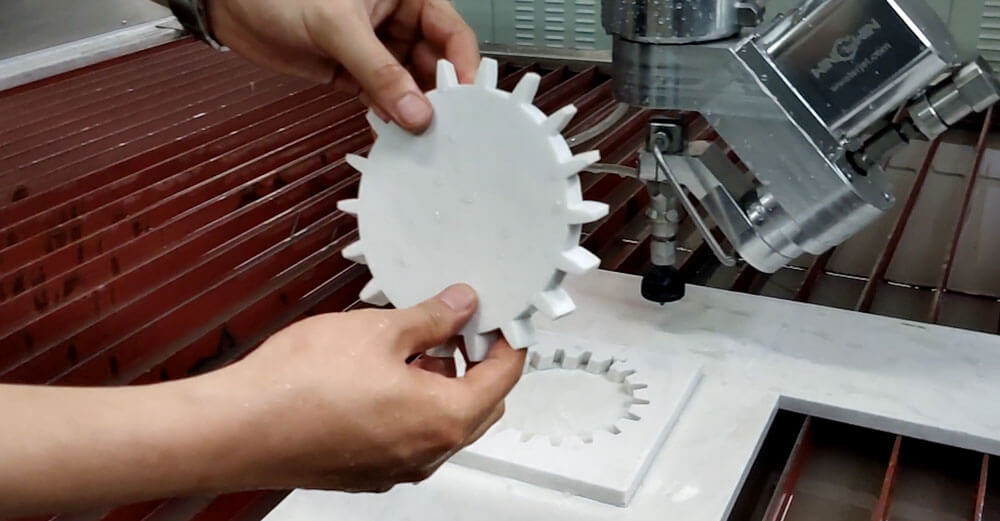

Waterjet cutting machine product description:The waterjet cutting machine uses high-pressure water and special sand for cutting. The cutting process has no sparks and no thermal deformation. This three-axis waterjet cutting machine is more used in metal cutting, marble cutting, glass cutting, rubber cutting, etc. industry, our waterjet cutting machine has the characteristics of high stability and high precision.

Waterjet cutting machine product features:

The ground available lifting system is adopted, which is suitable for large-scale plate loading, reducing the risk of personnel and material breakage

40HP ultra-high pressure pump, the pressure can reach 60.000psi, the cutting surface is smooth and the cutting speed is fast

The core of the intensifier is imported from the United States, ensuring long-term use

The waterjet cutting machine software and servo motors use the WEIHONG brand uniformly, with good compatibility and stability. The waterjet cutting machine software is easy to operate and can be used proficiently in one day

The cantilever structure, the water tank and the frame are separated to ensure the accuracy and stability of the machine tool

The whole waterjet cutting machine is protected by stainless steel, no corrosion, no rust, good dustproof effect

The underwater cutting structure can be customized to reduce noise and create a good environment

Adopt thick screw, large slider, or linear guide rail structure to ensure the stability of machine tool running at high speed

Series | 4020 Water Jet | Type | Cantilever Type |

Cutting Angle | 0 Degrees | Control Accurcy | ±0.01mm |

Table Size | 4000mmx2000mmx200mm | Travel Of Z Axis | 200mm |

Cutting Precision | ±0.1mm | RE-Positioning Accuracy | ±0.05mm/m |

Cutting Speed | 11000mm/min | Certificate | CE ISO |

Motor | 30kw / 40HP | After-sales Service | Installation Online Service |

MAX.Cutting Range | 4000mmx2000mmx200mm | Material | Stainless stee |

Introduction of main components of water jet cutting platform:

Cantilever structure, separate design of cutting platform and operating platform, avoiding the overall deformation of the machine affected by the load of the water tank

The X-axis of the cutting platform is made of aluminum alloy profile, which is light in weight, high in strength, and will not deform permanently.

The Y-axis of the cutting platform adopts a linear guide rail structure to ensure the stability of the operation. The linear guide rail of the large platform is more stable than the screw structure

Stainless steel full protective structure, can work stably in any complex environment

Focus on stability and use fewer parts with a compact cutting head

The water tank is made of 6mm thick steel plate, the grid width is 80cm, and the adjustable structure is adopted, which is more convenient for customers to use

The platform screw slider brand uses Taiwan ABBA brand, stability and life are guaranteed

Power | 40hp (30 kW) | Max. Water Flow Rate | 1.0 gpm (3.8 L/min) |

Max. Pressure | 60,000psi | Voltage | 380V/others |

Max. Orifice Dia. | .014 in. (0.36 mm) | Attenuator Volume | 1L |

Length | 1600mm | Hydraulic Reservoir Capacity | 114 L |

Width | 1200mm

| Weight | 0.9t |

Height | 1100mm | Continuous working pressure | 360Mpa-380Mpa |

Temperature | 5°-40° | Temperature | 115L |

WW5060 intensifier pump, cost-effective, good market versatility, the core parts of the intensifier pump are common in the market, and installed dual hydraulic oil filtration systems, three water filtration systems, independent variable pump, Sandvik high pressure pipe, full protection Structure, safe and reliable, the main feature of WW5060 intensifier pump is stable, suitable for metal industry, glass industry, rubber industry, marble industry, etc. WW5060 intensifier pump has been popular in the market for more than 20 years, it is a mature and stable intensifier pump, you can choose with confidence

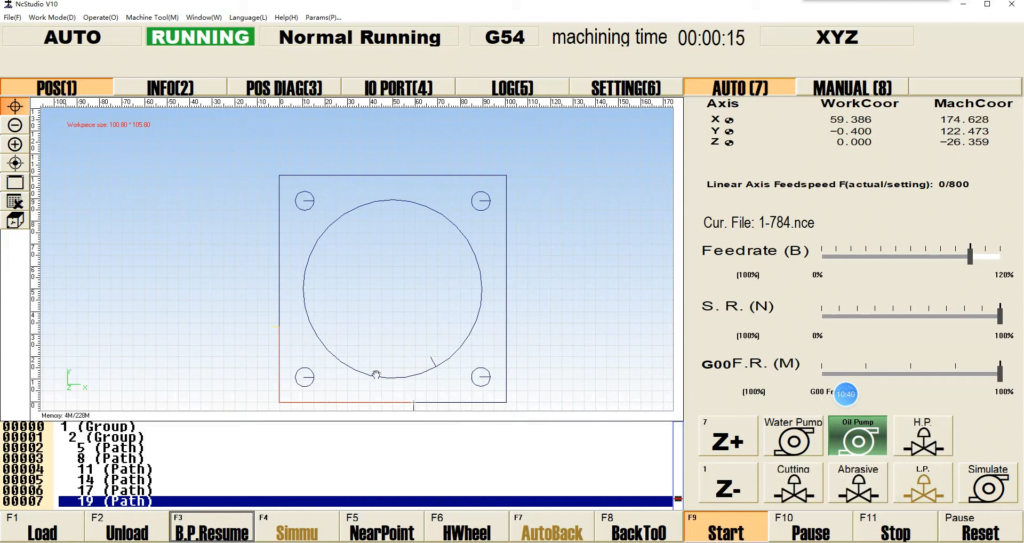

Waterjet cutting machine operating system features:

WEIHONG’s complete system and servo motor are adopted, with good stability and compatibility.

Most of the water jet cutting systems in China are WEIHONG brand, and the customer recognition is very high

The operation of the control system is very simple, and novices can master and apply it after a day of training

There are moving wheels under the operation cabinet to adjust the position

Equipped with wireless handle and wireless mouse and keyboard, very convenient to use

It has the functions of cutting simulation, consumable parts memory time, saving cutting data, etc.

This type of chiller is a refrigerator independently developed by Win-Win. The manufacturer customizes the production according to the technical requirements of Win-Win. The effect is to solve the high temperature problem of the intensifier pump, and the water is recycled. The oil temperature and water temperature of the intensifier pump can not be affected by the environment. , can be kept between 20°-25°, the use effect is very good, this type of chiller is different from the general refrigerators on the market, high-tech refrigerators can affect the trouble-free running time of the overall equipment

What’s the speed of waterjet cutting machine?

The average cutting speed of a waterjet cutting machine is about 15 centimeters per minute. However, cutting speed is a variable factor and is affected by many different factors. Compared to other alternative cutting techniques, such as electrical discharge machining (EDM), waterjet cutting is relatively fast, at approximately 1 cm per minute. For cutting speed measured in imperial units, a waterjet cutter can cut an average of about 12 inches per minute. Common cutting speeds range from 12 to 15 inches per minute. However, this does not represent the top speed of the waterjet cutter. For softer materials like marble and glass, waterjet cutters can cut about 90 inches per minute at impressive speeds. It should be noted that cutting speed is only one aspect of evaluating the performance of a waterjet cutter. In addition to speed, factors such as cutting quality, precision and material adaptability also need to be considered comprehensively. Therefore, when choosing a cutting technology, it is necessary to comprehensively consider cutting speed and other related factors to ensure the best cutting effect and production efficiency.

What factors affect the cutting speed of a waterjet cutting machine?

Many factors play an important role in waterjet cutting speed. Here are these factors and how to optimize them:

Material Thickness: Material thickness is a key factor affecting waterjet cutting machine cutting speed. Generally speaking, the thicker the material, the slower the cutting speed. To optimize the cutting speed, it can be adjusted according to the material thickness to ensure the highest speed without compromising quality.

Material Type: Different materials have different physical properties and therefore affect the cutting speed of the waterjet cutting machine. Can be optimized for different material types, understand their characteristics and adjust cutting parameters for optimum speed.

Selection of abrasives: Choose high-quality abrasives with appropriate particle size to improve cutting speed and effect. Appropriate abrasives can increase cutting force and speed up cutting.

Water pressure: Waterjet cutting machine systems use a wide range of water pressures, with higher pressures allowing faster cuts. But be aware that too much pressure will increase equipment wear and cost, so a balance needs to be found between speed and equipment durability.

Nozzle Diameter: A larger nozzle diameter can increase cutting speed because a larger nozzle diameter can pass more water. Be aware, however, that a large nozzle diameter will limit the ultra-high pressure of the waterjet, so there is a trade-off between speed and nozzle size.

Water quality: Water quality also has an impact on the cutting speed of a dynamic waterjet system. Make sure to use treated water to avoid impurities that can negatively impact cutting speed and equipment life.

Water Flow: According to specific application needs, adjust the water flow to obtain the best cutting speed and results. Higher water flow increases cutting speed but increases component wear and operating costs.

Cutting pattern: Straight lines cut the fastest, while sharp corners and frequent turns slow down the cutting speed. Optimize the cutting pattern, using rounded corners instead of sharp corners for continuous cutting without stopping.

Focus Tube Length: Longer focus tubes reduce waterjet velocity, reducing accuracy and cutting speed. Choose the appropriate length of focusing tube to maintain precision and speed.

Cone angle: The cone angle has little effect on the cutting speed, but a larger cone angle can increase the cutting speed. Need to find the best balance between speed and cutting accuracy.

Workholding: Proper selection and use of workholding can improve cutting speed and quality, ensuring that the workpiece is held securely with less movement. By optimizing these factors, the speed and efficiency of waterjet cutting can be maximized.

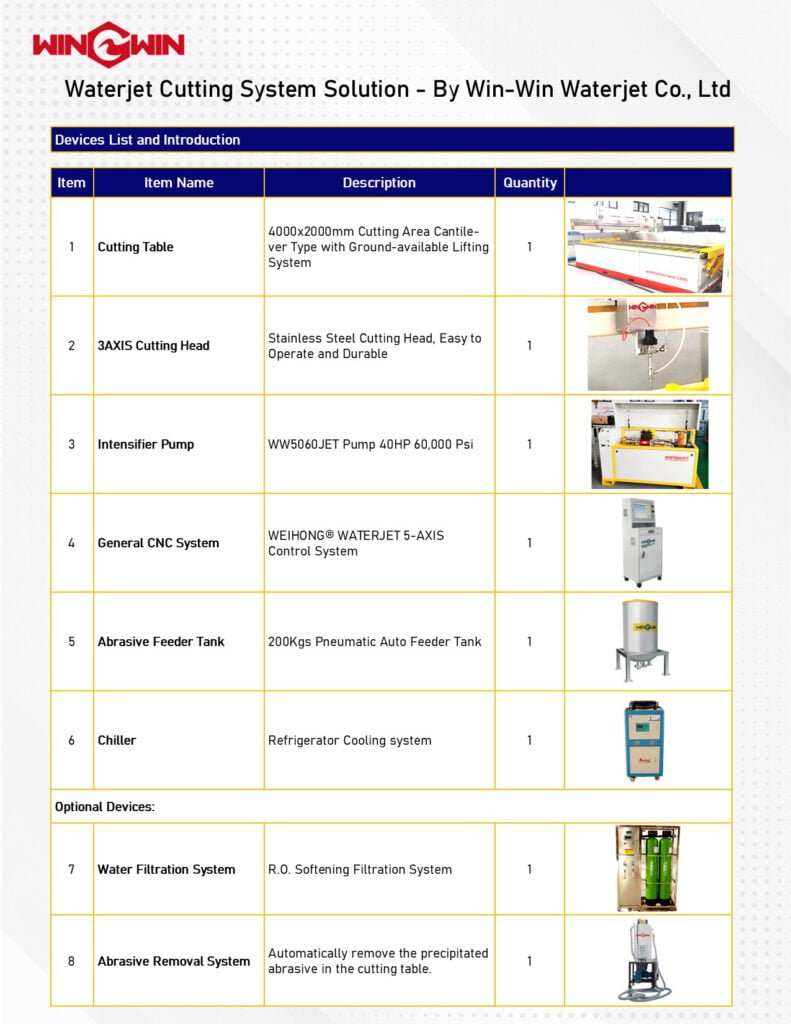

The table above is all the devices included in our complete set of waterjet cutting machine. This set of machine is an upgraded version, because it is equipped with a platform lifting system, which is more convenient for waterjet cutting users to load and unload. We are a waterjet supplier with customized production capacity. If you have cutting needs, you can leave us a message, and we will arrange professional people to answer for you.

Our main products include but not limited to: robot waterjet cutting system, abrasive waterjet cutting machine, portable waterjet cutting machine, high-pressure waterjet pump (60,000psi to 90,000psi and 100hp etc.), waterjet spare parts for major brand etc.

You can also pay attention to our YouTube channel, we will release some of our product cases and some related industry videos on YouTube from time to time for your reference.