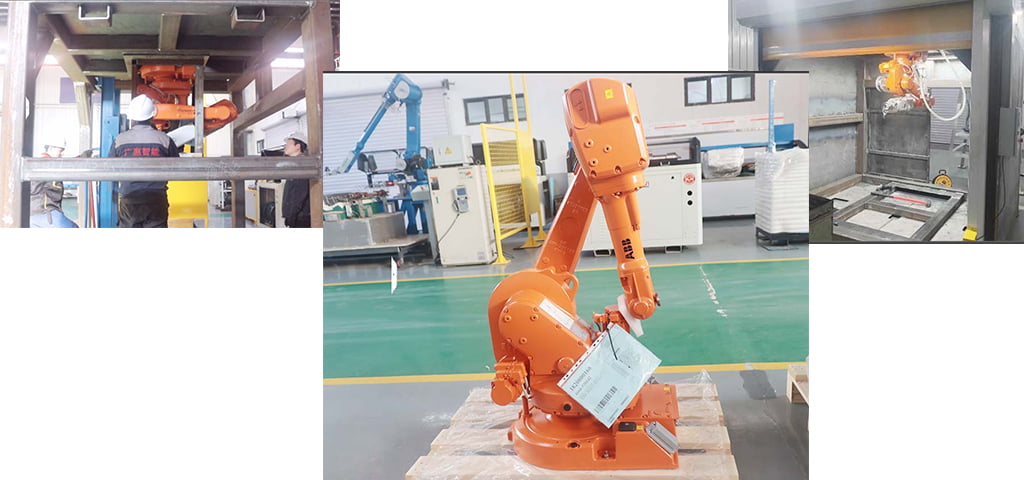

This set of robotic waterjet cutting equipment for cutting helmets is a waterjet cutting solution specially customized for customers according to their cutting requirements. This solution is equipped with ABB1600 robot arm, and the overall design is a full-protection ceiling type. According to the customer’s budget and production needs With our self-developed WW40JET waterjet intensifier pump, professional industrial chiller, water softening system, vacuum adsorption system, abrasive feed tank and also the auto abrasive removal system, you can see all related devices in the following video:

Win-Win provides a professional cutting solutions, the following is our basic process for determining the solution:

We will arrange experienced sales staff to connect with relevant businesses, and provide targeted solutions after fully understanding the customer’s cutting requirements and analyzing the customer’s basic situation. Our technicians will give a preliminary design model, The specific details in the later stage will be adjusted again according to the requirements of customers.

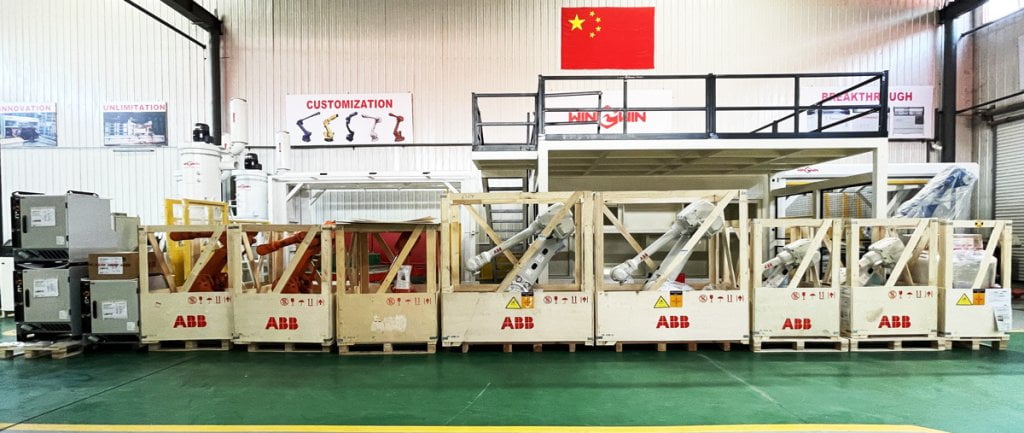

We cooperate with world-renowned robot brands ABB, FanUC, Kuka, etc. We will recommend corresponding products according to the needs of customers. After the final plan is determined, the production and processing of related devices and waterjet high pressure components will be carried out immediately, and assembly and debugging will be carried out.

After the continuous efforts of our technicians and workshop production workers, our whole set of equipment has been ready for trial cutting for customers after about half a month.

The whole set of equipment has passed the cutting test and pressing test. Because of the small size of this workstation, it can be packed in a 20-foot container for transportation.

Do you know what kind of helmet can be cut by waterjet machine?

Do you know what kind of helmet can be cut by waterjet machine?

Waterjet cutting can be used to cut various types of helmets made from materials that can be cut with this method. Some examples of helmet materials that can be cut with waterjet include:

Metal helmets: Waterjet cutting can be used to cut metal helmets made from materials such as steel, aluminum, and titanium.

Plastic helmets: Waterjet cutting can also be used to cut plastic helmets made from materials such as polycarbonate, ABS, and nylon.

Composite helmets: Waterjet cutting can be used to cut composite helmets made from materials such as carbon fiber, Kevlar, and fiberglass.

Foam helmets: Waterjet cutting may also be used to cut foam helmets made from materials such as expanded polystyrene (EPS) and polyurethane (PU).

The specific design and shape of the helmet can also impact its suitability for waterjet cutting. Helmets with complex shapes or intricate details may require a more specialized cutting approach or additional finishing steps to achieve the desired result.

Overall, it is important to consult with a professional waterjet cutting service provider such as Win-Win Waterjet to determine the best approach for cutting your specific type of helmet. They can evaluate the helmet material and design, and recommend the best method and cutting parameters to achieve the desired result while maintaining the structural integrity of the helmet.

We have rich experience in the design and production of robotic waterjet cutting solutions, including pedestal robot waterjet cutting system and ceiling type robot waterjet cutting system, etc., fully protected house-style design, more floor-saving two-story house-style design, with a flip table Fully protected house-style design, etc., the cutting solution can be equipped with single robot arms, double robot arms, three robot arms or more. Our high-flow booster pump can support up to six robot arms at the same time. In summary, if You are looking for a manufacturer of cutting solutions, please do not hesitate to contact us!!!