YASKAWA Robot Waterjet Cutting Solution

| 1 | Brand of robot: | YASKAWA |

| 2 | Quanlity of robot: | single |

| 3 | Type of robot: | Pedastal |

| 4 | Product number of robot: | GP20HL |

| 5 | Cutting type: | Pure water (water only) |

| 6 | Application: | Composite materials cutting |

| 7 | Pump type: | SCREAMLINE SL-VI (100HP) |

| 8 | Devices including: | Robot arm, cutting table, intensifier pump, chiller, etc. |

Now I want to show you this robot waterjet cutting solution:

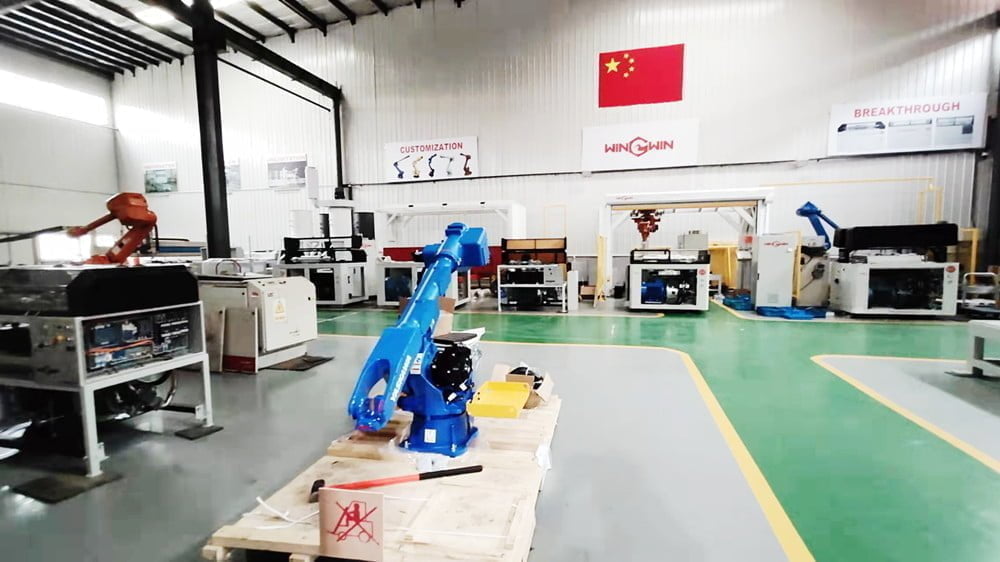

You can see from our pictures that this robot waterjet cutting workstation was built from scratch.

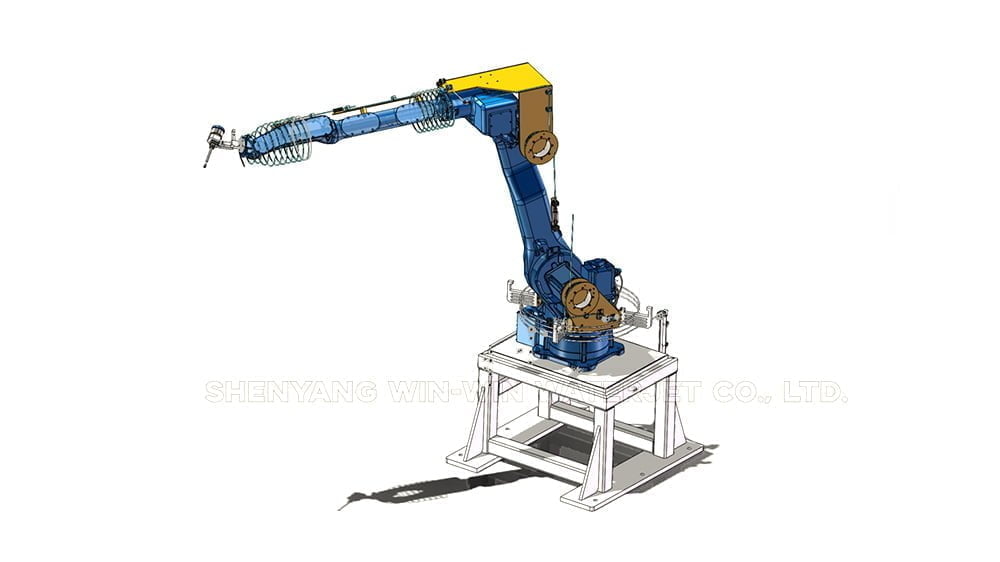

In the first step, we can see that this is a rendering of a robot arm with all coils, brackets, guards and cutting heads and other high voltage accessories, bases. This is the plan we have decided after in-depth discussions with the buyers of robot waterjet workstations, and then the design renderings we made.

In the second step, the robot arm is ordered and delivered. All the robots in the robot waterjet solution are selected from world-renowned brands, with good quality, stable performance, high precision, guaranteed after-sales service, and worldwide warranty. Users can choose the brand they want for the robot waterjet cutting solution, or let us recommend it.

The third step is to assemble the robot waterjet machine, fix the robot to the base, install all corresponding high-voltage accessories, place the cutting platform, connect the control system, high-pressure pump, refrigerator, vacuum adsorption machine, etc., all waterways, circuits, and air sources wait.

The third step is to debug and test the robot waterjet cutting workstation, to debug the performance and parameters of the machine to achieve the best state, and notify the customer for video inspection or factory inspection after completion.

The fourth step is to package and deliver the goods. After the acceptance of all equipment is completed, each device is carefully packaged and boxed.

These processes take about 1-2 months, different robot waterjet cutting solutions, different configurations or different brands of robots for robot waterjet cutting solutions, the time will vary.

What’s the robot waterjet cutting system?

A robotic water jet cutting system is an automated system that utilizes robotics and water jet technology for cutting and processing. It combines the flexibility of industrial robots with the high precision and no heat effect of water jet cutting, and is used for cutting, engraving and processing of various materials in the field of manufacturing and processing.

A robotic waterjet cutting system usually consists of the following components:

Robot: The industrial robot is the core component of the system, capable of precise motion control in three-dimensional space. It can position the water jet cutting head to the position where it needs to be cut according to the program and instructions, and move according to the predetermined path. The robot arms suppliers we have cooperated with include ABB, Fanuc, Kuka, Yaskawa etc.

Waterjet Cutting Head: A waterjet cutting head is a robot-connected device that generates and controls a water jet. It usually includes components such as high-pressure water pumps, nozzles, mixing chambers and regulating devices. The water jet cutting head can generate high-speed water jet, and adjust the water pressure, flow rate and nozzle diameter and other parameters according to the needs.

Control system: The robotic waterjet cutting system is equipped with a dedicated control system for programming and controlling the movement of the robot, as well as adjusting and monitoring the parameters of the waterjet. Control systems usually include programming software, motion controllers, sensors, and monitoring equipment.

The working principle of the robotic water jet cutting system is to accurately position the water jet cutting head to the part that needs to be cut by controlling the trajectory and speed of the robot through programming. At the same time, the control system will adjust the pressure and flow of the water jet to adapt to different materials and cutting requirements. Waterjet cuts or processes materials into desired shapes and sizes through high-speed jetting and shearing action.

Robotic water jet cutting system has the following advantages:

High precision: Water jet cutting can achieve high-precision cutting and processing, and can meet the requirements of complex shapes and details.

No heat impact: Since water jet cutting is a non-thermal cutting process, there will be no problems such as heat affected zone, discoloration or deformation, and it is suitable for various sensitive materials.

Multi-material suitability: Robotic waterjet cutting systems can handle a wide variety of materials, including metals, composites, plastics, stone, and more.

Automation and flexibility: Robot operation and programming can achieve automation and flexibility to adapt to different products and batch production needs.

Robotic water jet cutting systems are widely used in automobile manufacturing, aerospace, shipbuilding, architectural decoration and other fields, providing efficient, accurate and reliable cutting solutions for the production process.

How long does it take for a set of robot waterjet cutting equipment from design to shipping?

Which car parts can the robot waterjet cutting system cut?

Robot waterjet cutting technology can be applied to the cutting and processing of various materials in the interior and exterior of automobiles. The following is a list of some common automotive interior and exterior materials, which are suitable for robotic waterjet cutting:

plastic:

ABS (acrylonitrile-butadiene-styrene copolymer)

PC (polycarbonate)

PP (polypropylene)

PVC (polyvinyl chloride)

PE (polyethylene)

Fabrics and Textiles:

car seat fabric

roof fabric

Carpets and Flooring Materials

door trim fabric

leather:

seat leather

steering wheel leather

Door interior leather

center console leather

Wood and wood composites:

wooden decorative panel

wood floor trim

Wooden center console trim

Foam and padding materials:

Foam padding for seat and backrest

Foam padding for ceiling and door trim

Audio Soundproofing Material:

Audio Soundproofing Liner

soundproofing material covering

It should be noted that robotic water cutting technology is suitable for most non-metallic materials, including rigid materials and flexible materials. It can achieve high-precision cutting and processing without thermal impact, and is suitable for interior and exterior trims with complex shapes and detail requirements. However, for some special materials or specific cutting requirements, further evaluation and testing may be required to determine the suitability of robotic waterjet cutting.

How do you ship the robot waterjet cutting system?

Our robot waterjet cutting system usually uses a 20-foot container or a 40-foot container. All large pieces of equipment are packed with soft film, and the outer layer is fixed with straps, and small pieces are packed into plywood. wooden box. We provide overseas on-site installation and commissioning work, including equipment training, please contact us for details.

In addition, the highlight of our machine is our high-pressure pump. What are its advantages?

1. It is a large-flow pump, and its maximum flow can reach 7.6L/MIN, which means its cutting efficiency is higher than that of ordinary flow pumps; and it can simultaneously drive six 0.17mm orifice The cutting heads work simultaneously. The advantage of this function is that one pump can supply 6 robot arms to work at the same time, which will greatly save costs and improve production efficiency. It is a very popular pump in the automotive interior cutting industry.

2. The intensifier of this waterjet pump can be single or dual in the robot waterjet cutting solutions or other waterjet cutting applications. Customers can request to bring two intensifiers when purchasing, or add one after use. Then under what circumstances do you want to buy a pump with double intensifiers, or under what circumstances do you want to add one? The advantage of the double intensifier structure is that it can truly work 24 hours without stopping. When one of the intensifiers of the pump is in the situation of dismantling and repairing, we can switch to another intensifier to work. It is very beneficial for the processing industry with high efficiency requirements, heavy workload or deadlines.

If you are interested in our robot waterjet or intensifier pump, contact us please.

You can tell the industry you are in, the material you need to cut, we have rich experience in robot waterjet cutting, we have done cases in various industries, we can put forward very constructive suggestions and solutions of robot waterjet cutting for you.

If you want to use the robot waterjet in some relatively uncommon or uncommonly, used industries or material cutting, we are also happy to do research for you, because we have a strong and professional technical research and development team.

We will update our latest product solutions on YouTube channel, you can follow our account to get our latest industry-related consultation.