What is the portable waterjet cutting machine ?

Portable waterjet cutting machine is a very flexible, portable and multi-purpose water jet cutting method, especially widely used in outdoor and outdoor cutting operations. We can formulate suitable and efficient water jet cutting solutions according to customers’ cutting operation requirements.

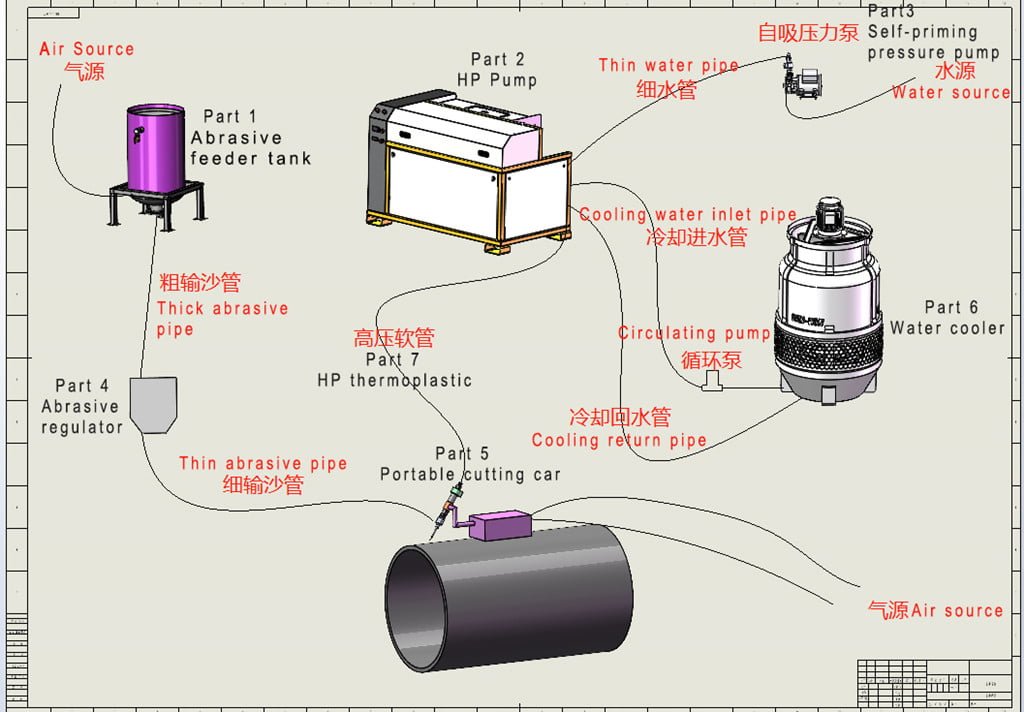

What components does Portable waterjet cutting machine include: cutting car, high-pressure intensifier pump, refrigerator, abrasive system, high-pressure pipe

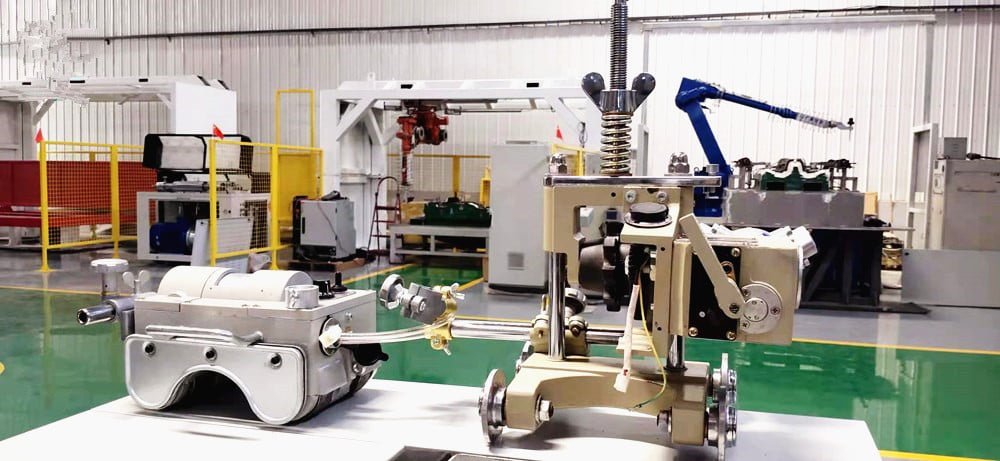

A, Type of cutting carriage:

1. Track-type trolley: Lay and fix the track on the material to be cut, and the cutting trolley will carry out the cutting operation along this track. This method is stable, not easy to move, and the cutting efficiency is higher. However, this trolley traveling method is generally suitable for cutting materials with relatively small diameters, because the use of rails for materials with super large diameters may be inconvenient to fix and the cost is too high. If the material with too large diameter needs to be cut, usually we will choose a 2-3 meter long guide rail to realize the travel of the trolley.

2. Magnetic trolley: The roller of the magnetic trolley is a device with permanent magnetism. The magnetism will never disappear, and the magnetism is very strong. It can be stably adsorbed on the surface of the iron that needs to be cut, and its movement can be controlled by remote control. Direction and speed, but the materials it can match are unique.

Driving mode of the car:

1. Electric: If it is convenient to provide power in the cutting environment, and the materials and environment to be cut are not afraid of the influence of electric sparks, then it is okay to choose electric.

2. Pneumatic: If the material to be cut and the environment are flammable and explosive, it is recommended to use a pneumatic trolley, which is safer and more assured.

3. Electro-pneumatic two-in-one: two driving modes, which can be switched and used at will.

4. Specifications of the magnetic cutting car:

| Parameters | Description | Parameters | Description |

| Body Size | 350 mm x 310 mm x 180 mm | Cutting Piping Width(diameter) | >130mm |

| Body Weight | 20 KGS | Cutting Accuracy | 1mm |

| Power | A/C 220V/50HZ | Magnetic Capacity | >50KGS |

5. Specifications of the straight walking car:

| Parameters | Description | Parameters | Description |

| Body Size | 470 mm x 230 mm x 240 mm | Power | A/C 220V/50HZ |

| Body Weight | 16 KGS | Cutting Accuracy | 0.1mm |

B, High pressure intensifier pump

1, Usually the portable waterjet cutting machine is equipped with our WW5060JET intensifier pump, its maximum pressure is 60,000psi, 30kw ordinary motor, it can cut various metals, tanks, pipes, etc.

3. For some flammable and explosive working environments, such as fuel tank pipelines, gas pipelines, etc., users and operators are very concerned about the safety of cutting tools, so Win-Win specially designed and assembled explosion-proof extension tools for this type of work. The pressure pump adopts an explosion-proof motor, and customizes explosion-proof electrical appliances and electrical boxes to reduce potential safety hazards in electricity use and provide users with a safe and secure cutting equipment.

C, Chiller

Win-Win has developed a professional refrigerator for waterjet machines, which has a remarkable cooling effect and can protect the intensifier pump for long-term effective operation.

D, Abrasive delivery system

Win-Win’s abrasive delivery system features thicker barrel walls for durability and explosion proof.

E, High pressure pipe

Win-Win has different high-pressure hoses to meet different cutting pressure requirements. We have 280mpa, 330mpa or 420mpa plastic hoses, which have certain flexibility and make the cutting head swing more flexibly. At the same time, we also have high-pressure metal pipes, both 420mpa and 600mpa (matching according to the pressure of the intensifier pump you choose), and the length can be customized.

So what job scenarios can portable waterjet cutting machines be used for?

1. Large and small storage oil tanks

2. Fuel pipeline

3. Gas pipeline

4. Dye storage tank

5. Wine and beverage fermenter

6. Vehicle accident rescue scene

7. Trees, stump cutting

In a word portable waterjet cutting machine suitable for chemical plants, ethanol plants, refineries, tank farms, environments with dust explosion risk, methane environments, etc.

Why portable waterjet cutting machine?

Unlike traditional three-axis and five-axis water jet cutting machines, portable waterjet cutting machines have a large footprint and have relatively high requirements for the site. The working site of Portable waterjet cutting machine is more flexible, and it is more suitable for outdoor processing operations. Its working principle is the same as any water jet cutting product. It is equipped with an ultra-high pressure waterjet pump to use pressurized water to cut objects. It’s just that the portbale waterjet cutting machine works with a magnetic trolley and a chain trolley, which is more suitable for cutting cylindrical objects such as pipes. Generally, large oil storage tanks are cut with a portable waterjet cutting machine.

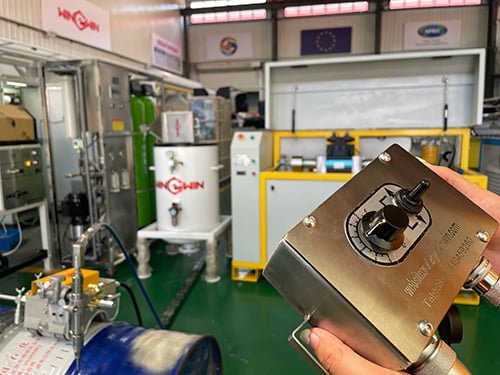

Versatile cutting head for portable waterjet cutting machine

We have a professional R&D department, which can customize different types of cutting heads to meet the cutting needs of different customers. Whether it is used for cutting underground pipelines in the mining industry, or for cutting large oil storage tanks in the petrochemical industry, we can design a cutting head Products tailored to customer needs.

Portable waterjet cutting machine is commonly used with cutting heads, diy type cutting head and the water gun. Different cutting heads have different application scenarios. If you don’t know which product to choose, you can contact us to explain your specific application and we will Recommend suitable solutions for you.

Is there a portable waterjet cutting machine?

Portable waterjet cutting machine is widely used in the field of pipe cutting in various industries, the most common is the cutting of oil storage tanks in the petrochemical industry, as well as the cutting of some mining pipes. Portable waterjet cutting machine portable carts generally have two forms, one is magnetic and can be adsorbed on circular metal pipes or work vertically, and the other is non-magnetic carts, which are suitable for pipe cutting , fixed by chains, generally suitable for cutting large oil storage tanks with relatively large diameters.

What’s the advantages of the portable waterjet cutting machine?

1. The portable waterjet cutting machine is a cold cutting method, suitable for cutting workpieces with water, without any thermal deformation or thermal influence, without changing the product properties of the material itself, especially suitable for cutting in the petrochemical industry Work without any sparks, and the risk factor is much safer than cutting methods such as lasers.

2. Applicable product range: suitable for cutting various pipes, such as: oil pipes, vacuum pipes. gas pipes and other high-risk pipes. For materials and shapes that require outdoor cutting operations, portable waterjet cutting machine is the best choice .

3. The operation is simple, the portable car in the portable waterjet cutting machine can be fixed on the pipe to be cut through the track, and the movement of the car can be controlled by a simple remote control, which is simple and safe.

Is there any warranty for portable waterjet cutting machine?

Regarding the quality assurance of portable waterjet cutting machine, different waterjet suppliers should have different standards, and the industry’s quality assurance period is generally about 1-3 years. This question needs to be consulted with the specific supplier to know that the general warranty items are large-scale products of the whole set of equipment, such as: waterjet pump, cutting car, waterjet abrasive feeder etc. such as waterjet high pressure piping, waterjet cutting head nozzle etc. These The products are all waterjet consumable products, which cannot be included in the scope of warranty, because these waterjet parts are products that need to be replaced regularly.

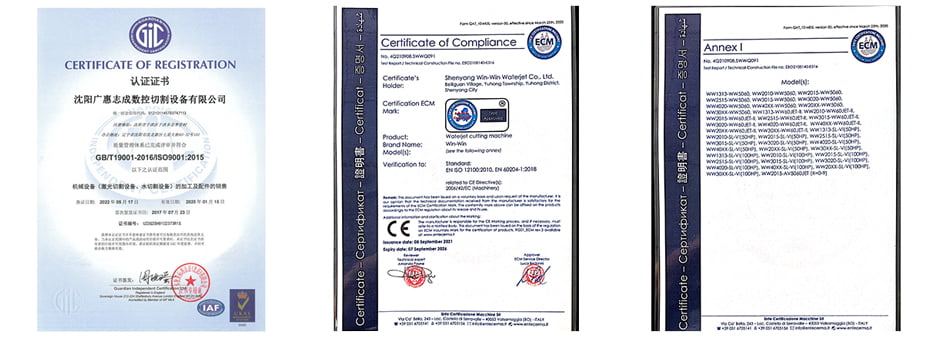

Do you have any certification for the portable waterjet cutting machine?

Win-Win Waterjet, as a leader in China’s waterjet cutting industry, has been deeply involved in the waterjet cutting industry for more than 20 years. We have served customers in more than 30 countries around the world. Up to now, we have obtained more than 30 invention patents related to ultra-high pressure, and have ultra-high pressure product technology of 60k psi and 90k psi. The product line includes: robotic waterjet cutting system cells, abrasive waterjet cutting machine, 3 axis waterjet cutter, AC 5 axis waterjet cutter; portable waterjet cutting machine; waterjet spare parts for major brand machine, etc. All of the above products have international standard CE and ISO certification.

Do you provide waterjet cutting service?

Strictly speaking, we are a waterjet supplier, we provide waterjet cutting equipment, but do not include waterjet cutting services. However, we provide customers with a complete water jet cutting solution, from the initial scheme design to the trial cutting service of the material specified by the customer. We will conduct the next consultation after the customer is very satisfied with the cutting effect. Up to now, we have tried dozens of products for customers, such as: steel cutting, glass cutting, metal cutting, stone cutting, marble cutting etc. These materials are the most common; there is also portable waterjet cutting machine to Cut pipes, etc., automotive interior products cut by robotic waterjet cutting system, car floor mats, roofs, etc. You can follow our YouTube channel, we will update some water cutting related product cases for your reference from time to time, if you have any questions, please feel free to contact us.