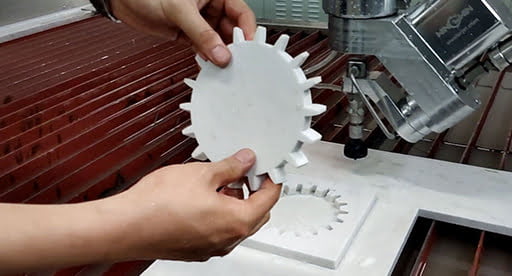

Marble and granite special waterjet cutting machine is suitable for the production and cutting of construction and decoration companies, kitchen countertops, bathroom products, etc.

This machine is equipped with AC-5 axis cutting system and cutting head, it can achieve multi-angle cutting production from 0-68 degrees, and meet the production needs of large-angle cutting, so it is the first choice for water jet cutting of marble, granite and other decorative stones equipment.

Features of AC-5aixs waterjet cutting head:

360°Rotation: C axis can rotate 360°around Z axis. X axis rotate A axis, realize large bevel 0°to 68°,can cut large angle groove, suitable for marble, steel material bevel cutting.

B. Automatic height measuring function: Automatic height measurement can cut rough parts, make 5 axis five linkage cutting come true.

Double insurance: It can completely solve the problem of limit collision caused by operational errors.

Two rotating axis: Extend the service life of rotary axis.

In the demand market of water jet equipment, the application of marble and granite cutting is very extensive, because most households and branches have kitchen or bathroom products made of marble or granite, the reason why these materials are very popular People love it because they are naturally formed materials, have no radiation, and have various naturally formed patterns, are very beautiful, never tire of looking at them, and durable, and they are smooth, shiny, waterproof, fireproof and insect proof. These are all reasons why it is popular and widely used.

Waterjet cutting machines are also the best machines for cutting these materials for the following reasons:

1. Characteristics of marble and granite: Natural marble is a metamorphic rock formed by the original rock in the crust through high temperature and high pressure in the crust. It is a medium-hard stone, mainly composed of calcite, limestone, serpentine and dolomite. Therefore, a large amount of dust will be produced when grinding and cutting with an ordinary cutting machine. These are harmful dusts, which not only pollute the environment, but also easily damage the health and cause diseases if they are inhaled by the human body in large quantities.

It is precisely because of the above characteristics that it is very necessary to choose a water jet cutting machine to cut marble and granite, because water jet cutting uses high-pressure water jets to cut, not only the cutting speed is fast, the cutting surface is smooth, and no dust will be generated. Thereby ensuring the health of operators and the environment will not be polluted