Описание

Waterjet pump parts Check Valve Repair Kit

Item number: 1004541

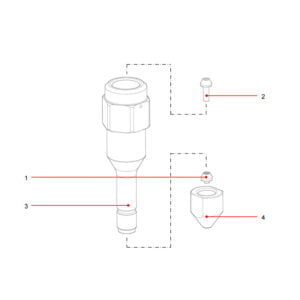

| 1027347 | Корпус клапана |

| 1004604 | Обратный клапан в сборе |

| 1003551 | Гидравлический поршень |

| 1003544 | Гидравлический цилиндр |

| 1003644 | Корпус фильтра |

| 1003433 | Адаптер обратного клапана |

| 1004146 | Гидравлический цилиндр |

| 1001653 | Уплотнительное кольцо высокого давления |

| 1009700 | Соединение |

| 1003302 | Фильтр высокого давления |

| 1004541 | Ремкомплект обратного клапана |

| 1004386 | Стопорное кольцо поршня |

FAQ of waterjet cutting machine & waterjet accessories:

- How much does waterjet cost?

- What’s the maximum feed of the machine?

The feedrate of a waterjet cutting machine can vary significantly depending on several factors, such as the material being cut, the thickness of the material, the pressure and flow rate of the waterjet, and the cutting nozzle diameter. In general, the feedrate of a waterjet cutting machine can range from a few inches per minute (IPM) up to several hundred IPM. For example, cutting through thick steel may require a slower feedrate, while cutting through thin aluminum may allow for a faster feedrate. It’s important to note that the feedrate of a waterjet cutting machine should be optimized for each specific cutting job to achieve the best results in terms of cutting speed and accuracy, while minimizing material waste and machine wear. Normally, the feed of garnet is about 5-30 kgs per hour of the abrasive waterjet cutting machine.

The function of the waterjet pump parts check valve in a hydraulic system is to allow fluid to flow in one direction only. It is a type of valve that allows fluid to flow through it in one direction, while preventing backflow in the opposite direction.

In a hydraulic system, check valves are typically used to prevent the fluid from flowing back into the pump or other components of the system when the pressure drops or the pump is turned off. This helps to maintain system pressure and prevent damage to the system components.

Check valves can also be used to isolate different sections of a hydraulic system, preventing fluid from flowing between them. This can be useful for controlling the flow of fluid to different parts of a machine or system.

Overall, check valves play an important role in maintaining the proper functioning and safety of hydraulic systems, by ensuring the fluid flows in the intended direction and preventing damage or malfunction due to backflow.