Описание

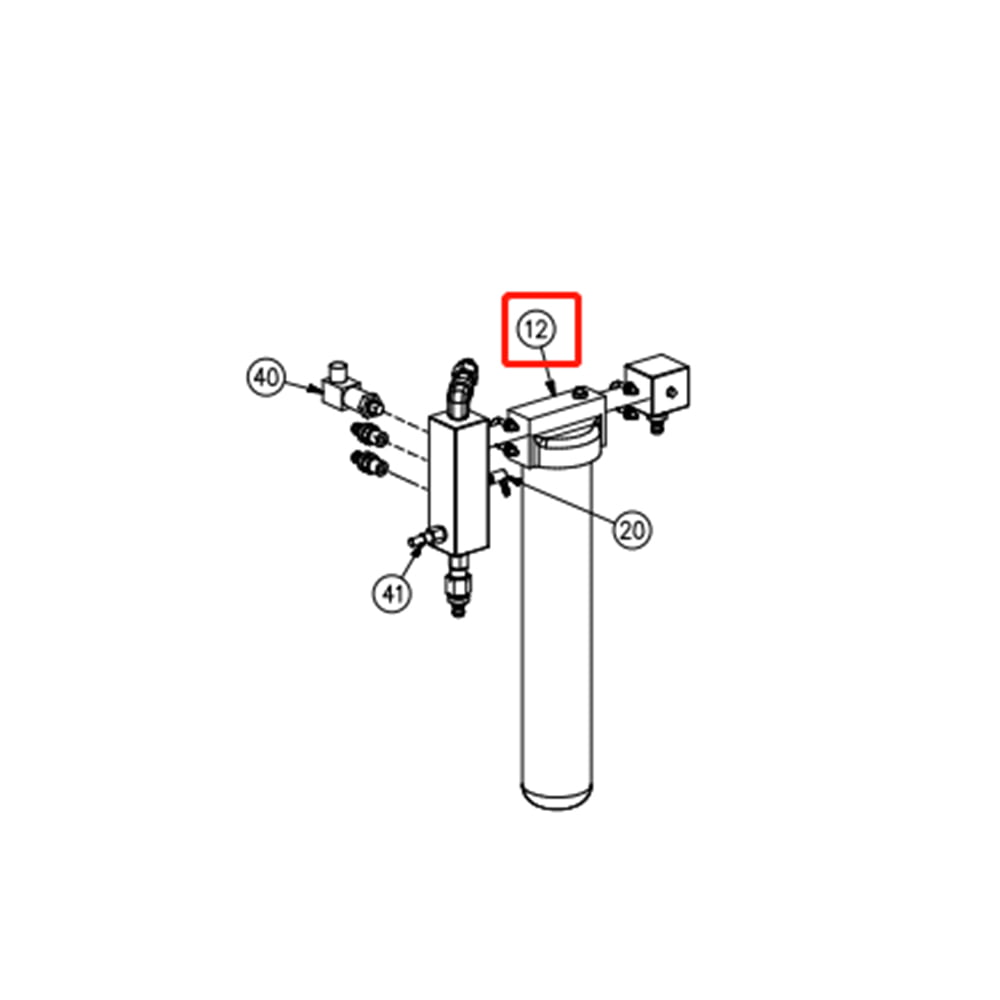

Waterjet parts: LP water filter assembly

Item number: 80087976

ПодробностьS: Используется на станке гидроабразивной резки SL-VI мощностью 100 л.с.

Сопутствующие детали для гидроабразивной резки:

| Артикул | Описание |

| 72119536 | Детали гидроабразивной резки Цилиндр высокого давления |

| 05144506 | Детали гидроабразивной резки Керамический плунжер |

| 20416445 | Детали гидроабразивной резки Гидравлическая головка блока цилиндров |

| 72110979 | Детали гидроабразивной резки Узел уплотнительной головки |

| 05149711 | Детали гидроабразивной резки Уплотнение высокого давления в сборе |

| 49838220 | Детали гидроабразивной резки Гайка цилиндра высокого давления |

Часто задаваемые вопросы о платформенном гидроабразивном станке и т. Д.:

How does a CNC waterjet cutter work?

CNC water jet cutter is a cold cutting method that uses ultra-high pressure water with a very small diameter to act on the surface of the object to be cut to achieve the purpose of cutting. Usually, abrasives are added during cutting, and the inside of the cutting head There is a mixing chamber, where water and abrasives will be fully mixed and then enter the nozzle to achieve cutting.

The process involves the following steps: Design:

The first step in using a CNC water jet cutter is to create a design or drawing of the part to be cut. This can be done using computer-aided design (CAD) software.

Programming: Once the design is complete, the operator uses CAM (Computer-Aided Manufacturing) software to convert the design into machine-readable code that the CNC water jet cutter can understand.

Setup: The operator sets up the cutting material, the water jet nozzle, and the abrasive delivery system. The material to be cut is placed on a cutting table, and the nozzle is positioned above it. Cutting: The CNC water jet cutter uses the programmed code to control the movement of the nozzle over the material. The high-pressure water and abrasive mixture are forced through the nozzle, creating a high-velocity jet that cuts through the material.

Finishing: After the cutting work is completed, if the cut surface needs to be polished and polished for the second time, the object needs to be moved to other machines to continue the operation. If it is a relatively large object, our machine is equipped with an automatic lifting system to complete the loading and unloading of the item. CNC water jet cutting offers several advantages over traditional cutting methods, such as greater precision, faster cutting speeds, and the ability to cut a wider range of materials. Additionally, the CNC technology allows for more complex shapes and designs to be cut with greater accuracy.