Описание

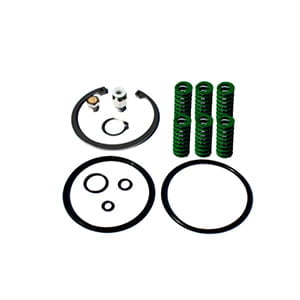

Waterjet manufacturers 500-20-0037 Ruby Orifice 0.011″

| ОБРАЗ | Артикул | ИМЯ | ||

|---|---|---|---|---|

| 500-19-0052 | Масляный фильтр 5 микрон | |||

| 500-3-0017 | Масло, 20 литров | |||

| 500-3-0016 | Масло, 5 литров | |||

| 500-20-0100 | Внешний корпус | |||

| 10079291 | Плунжер (только для квадратного корпуса клапана) | |||

| 5039771 | Вантуз | |||

| 05039771 | Вантуз | |||

| ЭЛ-46 | Вантуз | |||

| СП-46-1 | Вантуз | |||

| СП-46-3 | Вантуз | |||

| 5116751 | Тапоточный штифт | |||

| 05116751 | Тапоточный штифт | |||

| 10084440 | Pure Thread Goop, 1 унция | |||

| 12967 | Repair Kit NO (Needle,Seat,Seal,Brass & SST Backup,oring) | |||

| ВДЖ0Т2-1-025 | Резиновая крышка подъемного рычага | |||

| ВДЖ0Т2-1-025ТП | Резиновая крышка подъемного рычага | |||

| 500-5-0015 | Резиновый реечный чехол для кровати | |||

| 500-20-0036 | Рубиновое отверстие 0.010" | |||

| 500-20-0037 | Рубиновое отверстие 0.011" | |||

| 500-20-0038 | Рубиновое отверстие 0.012" | |||

| 500-20-0039 | Рубиновое отверстие 0.013" | |||

| 500-20-0040 | Рубиновое отверстие 0.014" | |||

| 20428052Н | Тюлень | |||

| 20428052 | Уплотнительная сборка | |||

| 49834039Н | Корпус уплотнительной головки (старого образца) |

Знание Станок гидроабразивной резки и Запасные части для гидроабразивной резки от Win-Win Производители гидроабразивной резки:

Helmets are made of different materials and designed for different uses, so the most suitable cutting method may be different. In general, helmets are usually made of metal or plastic, so high pressure water jet cutting is often required.

Often, helmet materials can be cut more quickly using abrasive waterjet cutting of Производители гидроабразивной резки. Abrasive water jet cutting uses a high-pressure water jet and fine grit particles to make it easier to cut metal, especially thicker metals. However, it is important to note that this method of cutting produces more waste and dust and can cause wear and tear on the cutting equipment.

In contrast, pure water cutting uses a high-pressure water jet of Производители гидроабразивной резки to cut helmet material without the use of any grit. This method cuts complex shapes of helmets more accurately and without generating dust and scrap. However, it may take longer for thicker metal materials to complete the cutting task.

Therefore, the choice between abrasive water jet cutting of Производители гидроабразивной резки or pure water cutting depends on the specific material of the helmet and the cutting requirements. It is best to conduct tests beforehand to determine the most suitable cutting method.

Беспроигрышный вариант Производители гидроабразивной резки для Станок гидроабразивной резки и Запасные части для гидроабразивной резки, Если вам нужны какие-либо гидроабразивные процедуры, Свяжитесь со мной, пожалуйста

The following video is showing our waterjet cutting machine from Win-Win Производители гидроабразивной резки с загрузочным устройством напольного типа.