Описание

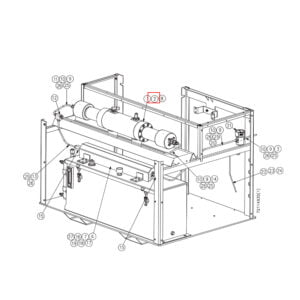

05144217 TOPWORKS.INTENSIFIER. SLIVPLUS waterjet intensifier

Основные части насоса SL-IV 50 л.с.:

| Пункт | Номер продукта. | Наименование продукта | Картина |

| 1 | 05144647 | Цилиндр высокого давления |  |

| 2 | 05144688 | Узел уплотнительной головки |  |

| 3 | 05144696 | Прокладка уплотнительной головки |  |

| 4 | 05144712 | Гильза цилиндра |  |

| 5 | 05149703 | Сборка уплотнения |  |

| 6 | 05130091 | Гидравлический картридж |  |

| 7 | 05119151 | Керамический плунжер |  |

| 8 | 05116561 | Тарельчатый тарельник HP |  |

| 9 | 05116751 | Тарельчатая булавка |  |

| 10 | 05144670 | Фиксатор тарельчатого тарельника |  |

Знания для Станок гидроабразивной резки и Запасные части для гидроабразивной резки.

The waterproof way of water jet cutting machine platform: (waterjet intensifer parts)

Waterproofing your water jet cutting machine platform is critical to ensure the proper operation of your cutting machine and the safety of your operators. Below are some common ways to waterproof the machine platform: (waterjet intensifer parts)

Sealing design: Ensure that the various interfaces, connections and openings of the cutting machine platform are well sealed. Use waterproof sealants, rubber gaskets, and other sealing materials to fill and seal potential water entry points and prevent water from penetrating inside the machine. (waterjet intensifer parts)

WATERPROOF COATING: Treat the surface of the cutting machine platform with a waterproof coating to enhance its waterproofing properties. This can be accomplished using specialized waterproofing paints, coatings or sealants. The coating should cover the entire surface of the platform and ensure the integrity and durability of the coating. (waterjet intensifer parts)

Drainage system: A drainage system should be provided on the cutting machine platform to effectively remove water and waste liquids generated during the cutting process. This can be achieved by installing equipment such as drainage tanks, drainage pipes and drainage pumps. The drainage system should be well designed to ensure that water can be drained quickly and efficiently and to prevent stagnant water and liquids from being retained. (waterjet intensifer parts)

Waterproof covers and baffles: Install waterproof covers and baffles around the cutting machine platform to prevent water and waste liquids from spilling out of the platform area. These covers and baffles prevent water from spreading and splashing and keep the surrounding environment dry and clean. (waterjet intensifer parts)

Design of the operating area: Design the operating area of the cutting machine platform to ensure that water and waste liquids do not splash onto the operator or the surrounding area. This can include sensible worktop design, waterproof enclosures and guards, etc. (waterjet intensifer parts)

Regular maintenance: Regularly inspect and maintain the waterproofing of the cutting machine platform. Check the integrity and damage of sealing components and replace worn or deteriorated seals in a timely manner. Ensure that the drainage system is unobstructed and functioning properly. (waterjet intensifer parts)

Если вас интересует любая гидроабразивная продукция от Win-Win Поставщик гидроабразивной резки, Свяжитесь со мной, пожалуйста.

В видео ниже показан наш новый заказ на два усилительных насоса SL-VI (50 л.с.) 60000 фунтов/кв. дюйм гидроабразивная резка При тестировании, упаковка к отгружению: