Описание

Waterjet Cut Parts: Retaining Ring 20492123

The retaining ring 20492123 is a specific type of retaining ring that is commonly used in Гидроабразивные насосы 90 000 фунтов на квадратный дюйм.

Retaining rings are used to secure various waterjet cut parts of the pump, such as the manifold, the cylinder, and the waterjet nozzle.

Пункт | Номер детали | Описание | Количество | Пункт | Номер детали | Описание | Количество |

1 | 05146592 | Прокладка, опора Topworks | 2 | 14 | 72162253 | Вантуз | 2 |

2 | 20476377 | Поддержка, Topworks | 2 | 15 | 05130091 | Картридж гидравлического уплотнения | 2 |

3 | 10118206 | Уплотнительное кольцо, 1,31×1,56× .13 | 2 | 16 | 72175989 | Фланец фиксатора втулки | 2 |

4 | 05144514 | Гидравлический цилиндр | 1 | 17 | 72158494 | Узел уплотнения UHP | 2 |

5 | 05098991 | Винт с торцевой головкой, 3/8-16×3-3/4 | 8 | 18 | 72166738 | Цилиндр UHP | 2 |

6 | 95688743 | Стопорная шайба, .38 | 8 | 19 | 72163802 | Лайнер | 2 |

7 | 72101190 | Поршень в сборе | 1 | 20 | 20474325 | Шпилька, 1-1/8-12×18.31 | 8 |

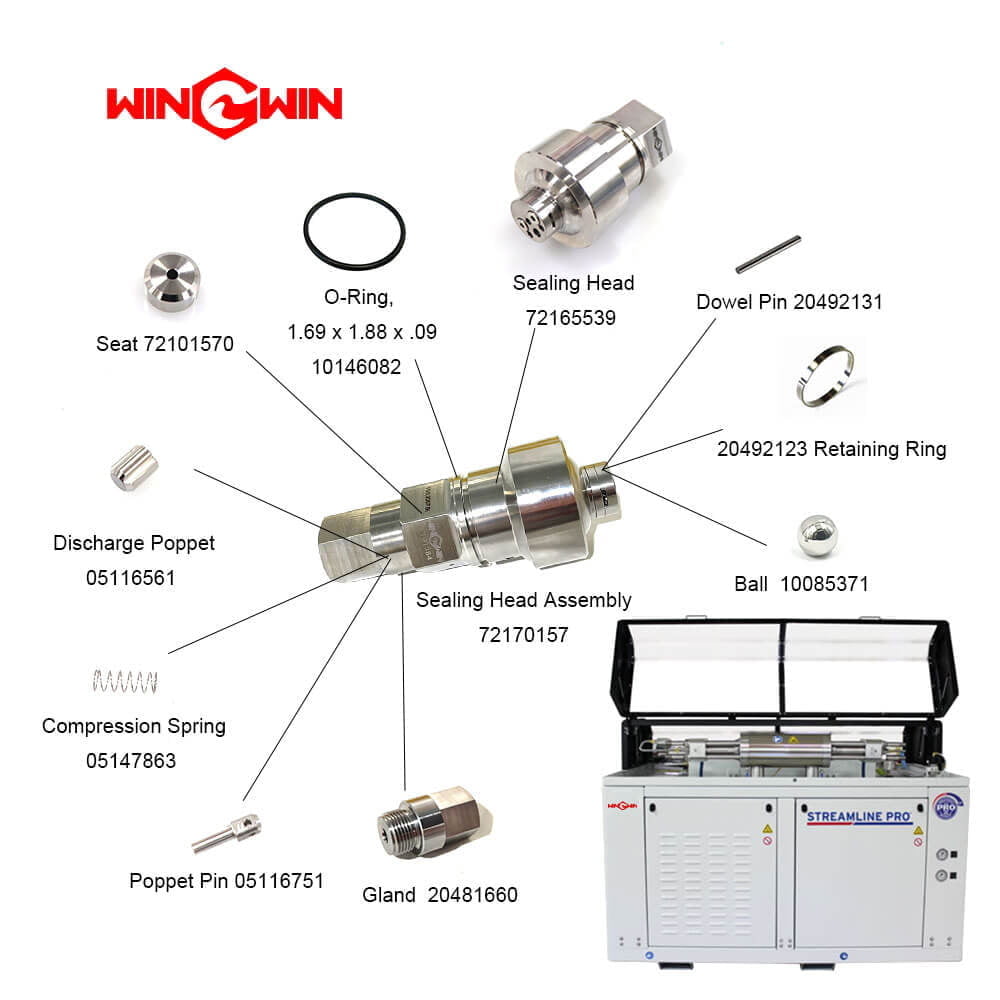

8 | 10074771 | Уплотнительное кольцо, 5,25×5,50× .13 | 2 | 21 | 72170157 | Уплотнительная головка в сборе | 2 |

9 | 05120092 | Резервное кольцо, 5.25×5.50×.13 | 2 | 22 | 72178493 | Сборка фланца | 2 |

10 | 72175997 | Гидравлическая головка блока цилиндров | 2 | 23 | 20464590 | Плоская шайба, 1.13 | 8 |

11 | 05097886 | Винт с торцевой головкой, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Шестигранная гайка, 1-1/8-12 | 8 |

12 | 05144183 | Распорка в сборе, бесконтактный выключатель | 2 | 25 | 20489339 | Адаптер, JIC/труба, 50×.38 | 1 |

05144191 | Уплотнительное кольцо, .69×.88×.09 | 26 | 72176756 | Уплотнительное кольцо, 3,88×4,25× .19 | 6 | ||

13 | 72141569 | Комплект, бесконтактный выключатель | 2 | ||||

| 72134224 | Бесконтактный переключатель | ||||||

95119012 | Винт с торцевой головкой, 1/4-20×1 |

Here are some details of the retaining ring 20492123 used as waterjet cut parts in 90,000 psi waterjet pumps:

1. Type of retaining ring

The retaining ring 20492123 is a specific type of retaining ring known as an external retaining ring.

It is designed to fit around the outside circumference of a shaft or other waterjet cut parts.

External retaining rings are commonly used in high-pressure waterjet pumps to secure components such as the manifold or cylinder.

2. Material composition

Retaining rings used as waterjet cut parts in high-pressure waterjet pumps are typically made from high-strength materials.

The materials are hardened steel or other alloys that can withstand the high pressures and vibration of the pump.

3. Size and dimensions

The retaining ring 20492123 has a specific size and dimension, with an outer diameter of 2.375 inches and a thickness of 0.062 inches.

This size is designed to fit specific waterjet cut parts of the pump, such as the manifold or cylinder.

4. Pressure rating

Retaining rings used as waterjet cut parts in 90,000 psi pumps need to be able to withstand the high pressure of the water and hydraulic fluid in the pump.

The pressure rating of a retaining ring refers to the maximum pressure it can withstand without failing or becoming dislodged.

5. Heat treatment

Some retaining rings used as waterjet cut parts in 90,000 psi pumps may undergo a heat treatment process to enhance their strength and durability.

This can involve heating the ring to a specific temperature, then cooling it rapidly to create a stronger, more durable material.

6. Installation and removal

Retaining rings used as waterjet cut parts in 90,000 psi pumps should be installed and removed using proper techniques and tools to prevent damage or distortion.

It’s important to follow our manufacturer’s recommended installation and removal procedures to ensure optimal performance and prevent leaks or other issues.

7. Maintenance and replacement schedule

Retaining rings used as waterjet cut parts in 90,000 psi pumps should be regularly inspected for signs of wear or damage.

And they should be replaced as needed to maintain optimal performance and prevent leaks or other issues.

The frequency of replacement can vary depending on several factors, such as the specific application, operating conditions, and maintenance practices

Contact us for assistance.