Описание

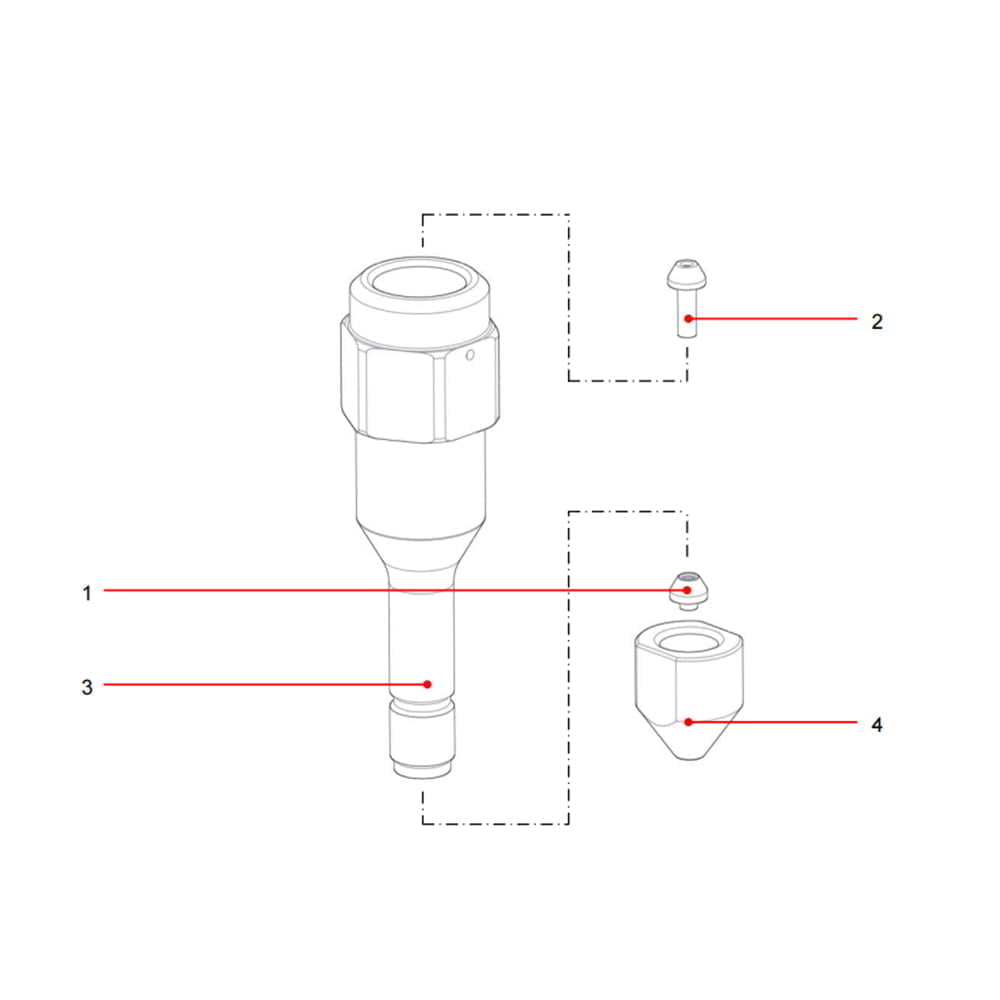

Waterjet accessories Pure Waterjet Cutting Head Parts

| Inner Diameter | Артикул | |

| Отверстие | 0.10mm | 1000376 |

| 0.12mm | 1000377 | |

| 0.15mm | 1000378 | |

| 0.175mm | 1000379 | |

| 0.20mm | 1000380 | |

| 0.25mm | 1000381 | |

| 0.30mm | 1000382 | |

| 0.35mm | 1000383 |

Related waterjet accessories of the pure cutting head assembly:

| Артикул | Описание |

| 1004442 | Lens ring |

| 1053801 | Pure water extension tube |

| 1053802 | Nozzle adapter |

Other related waterjet accessories:

| 1027347 | Корпус клапана |

| 1004604 | Обратный клапан в сборе |

| 1003551 | Гидравлический поршень |

| 1003544 | Гидравлический цилиндр |

| 1003644 | Корпус фильтра |

| 1003433 | Адаптер обратного клапана |

| 1004146 | Гидравлический цилиндр |

| 1001653 | Уплотнительное кольцо высокого давления |

| 1009700 | Соединение |

| 1003302 | Фильтр высокого давления |

| 1004541 | Ремкомплект обратного клапана |

| 1004386 | Стопорное кольцо поршня |

FAQ of waterjet cutting machine & waterjet accessories: Under what circumstances will a pure waterjet cutting head be used?

First of all, you have to understand the basic working principle of waterjet cutter. Waterjet cutter is a machine that uses ultra-high pressure water jet generated by waterjet pump to cut objects. Generally, pure waterjet cutting head is used to cut relatively soft materials, and most of them Car interior and car exterior manufacturers also use pure waterjet cutting head.

Pure waterjet cutting head is designed to generate high pressure water flow without the application of abrasive garnet, the waterjet nozzle is the key part of the cutting head part, because it can shape the water flow and control its direction and speed. The pure waterjet cutting head is usually made of wear-resistant and durable materials that can withstand high pressure and water flow. The common ones are rubby orifice and diamond orifice. The price of rubby orifice is relatively cheap, but the service life is relatively short and needs to be replaced frequently; but diamond The price of orifice is relatively high, but the service life is several times that of ordinary ruby orifice, which can effectively reduce the number of disassembly and assembly of related parts and reduce wear and tear.

Another advantage of pure waterjet cutting is that the edge of the cutting material is smooth, without burrs, and does not generate any mechanical stress or thermal stress, so it is very suitable for the aerospace industry, automotive industry and electronics industry.

If you are looking for a cutting solution, please contact us, we can provide you with professional advice for your reference.