Описание

Waterjet accessories Plunger

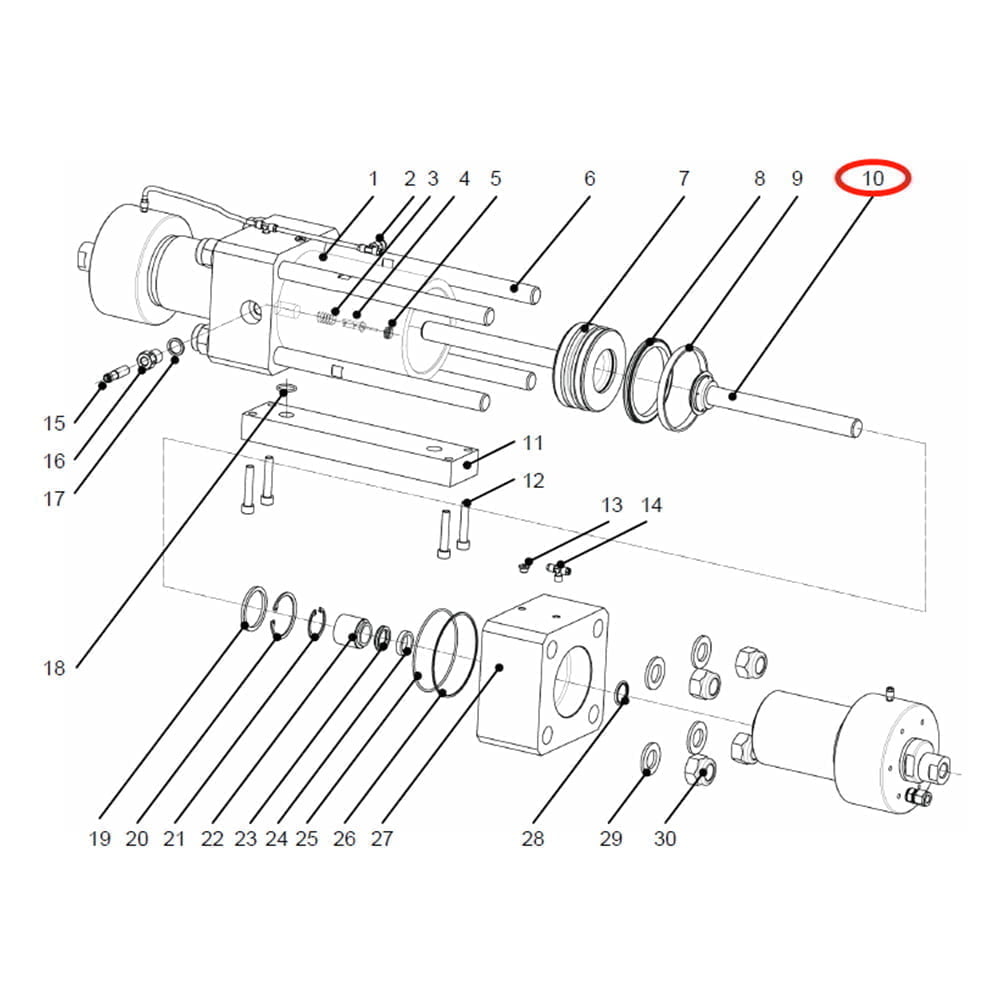

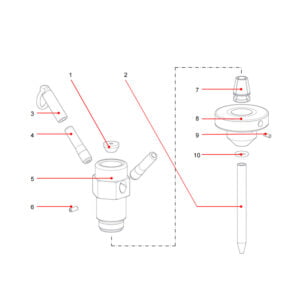

| Артикул | Описание | Количество |

| 1005322 | Вантуз | 2 комплекта |

Usage: Normally, a waterjet intensifier usually has two symmetrical waterjet plungers, one on the left and one on the right of the waterjet piston.

Сопутствующие аксессуары для гидроабразивной резки:

| 1027347 | Корпус клапана |

| 1004604 | Обратный клапан в сборе |

| 1003551 | Гидравлический поршень |

| 1003544 | Гидравлический цилиндр |

| 1003644 | Корпус фильтра |

| 1003433 | Адаптер обратного клапана |

| 1004146 | Гидравлический цилиндр |

| 1001653 | Уплотнительное кольцо высокого давления |

| 1009700 | Соединение |

| 1003302 | Фильтр высокого давления |

| 1004541 | Ремкомплект обратного клапана |

| 1004386 | Стопорное кольцо поршня |