Описание

05148861 TUBE HP 3/8″BENT SLIV FD TOPW. water jet fitting

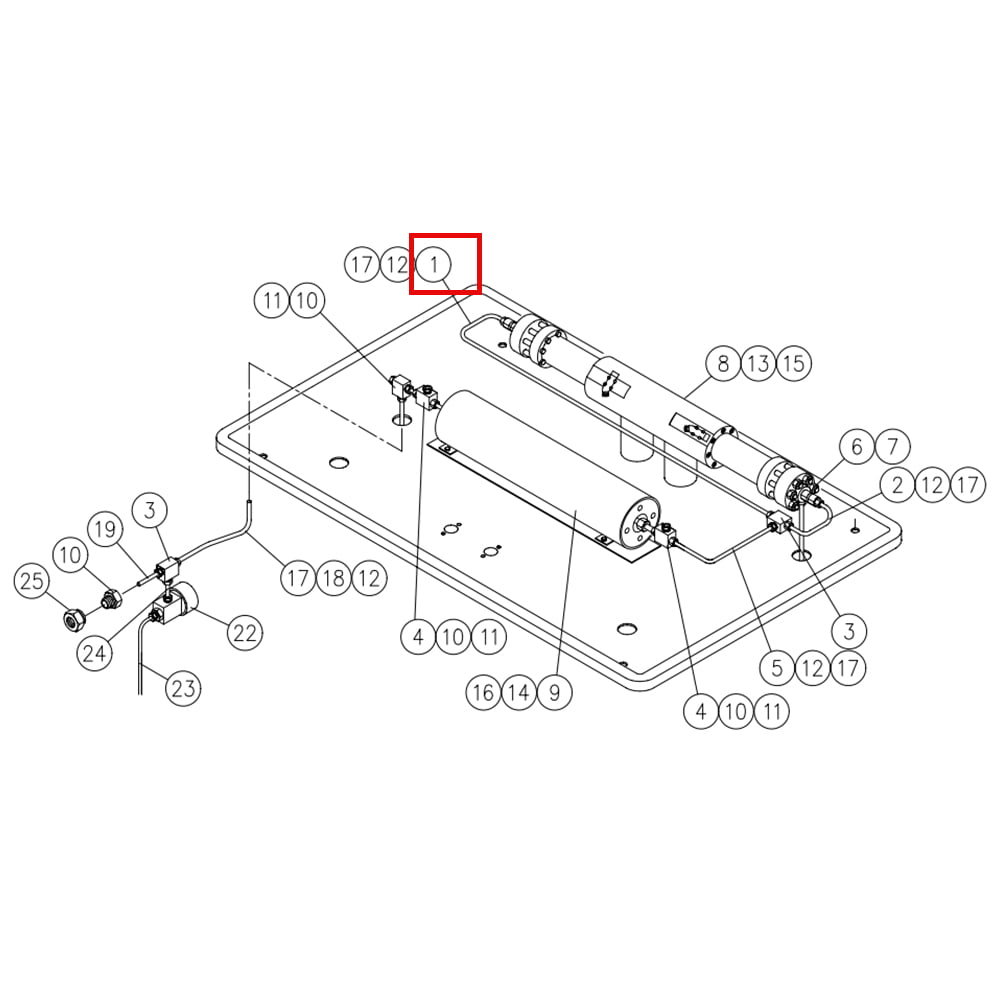

Основные части насоса SL-IV 50 л.с.:

| Пункт | Номер продукта. | Наименование продукта | Картина |

| 1 | 05144647 | Цилиндр высокого давления |  |

| 2 | 05144688 | Узел уплотнительной головки |  |

| 3 | 05144696 | Прокладка уплотнительной головки |  |

| 4 | 05144712 | Гильза цилиндра |  |

| 5 | 05149703 | Сборка уплотнения |  |

| 6 | 05130091 | Гидравлический картридж |  |

| 7 | 05119151 | Керамический плунжер |  |

| 8 | 05116561 | Тарельчатый тарельник HP |  |

| 9 | 05116751 | Тарельчатая булавка |  |

| 10 | 05144670 | Фиксатор тарельчатого тарельника |  |

Знания для Станок гидроабразивной резки и Запасные части для гидроабразивной резки.

Does the cutting efficiency change the higher the flow rate of a water jet cutting machine at the same pressure?

Cutting efficiency usually improves the higher the flow rate of a water jet cutting machine at the same pressure. This is because increasing the flow rate of the water jet increases the impact and cooling effect on the cutting area, which improves the quality and speed of the cut.

Specifically, increasing the flow rate of the Гидроабразивный фитинг water jet achieves the following results:

Increased Impact: The impact of the Гидроабразивный фитинг water jet is one of the key factors in cutting an object. Increasing the flow rate can increase the impact force of the water jet Гидроабразивный фитинг, making it more effective in penetrating and cutting the material.

Improved Cooling: During the cutting process, the Гидроабразивный фитинг water jet acts as a coolant to the cutting area, preventing overheating and damage to the material. Increasing the flow rate can provide more water for cooling, effectively lowering the temperature of the cutting area and reducing the heat-affected area, thus improving the cutting quality.

Enhanced cleaning effect: The Гидроабразивный фитинг water jet cutting process produces a large amount of slag and cutting residue. Increasing the flow rate can increase the scouring force of the water jet on the residue, better clearing the cutting area, reducing the number of repeated cleanups and improving the cutting efficiency.

It should be noted that increasing the flow rate of the water jet may also increase the consumption of energy and water resources, and may require more powerful pumps and systems to support the higher flow rate. Therefore, in practice, it is necessary to take into account the cutting needs, resource consumption and equipment capacity to choose the appropriate flow rate to achieve the best cutting efficiency.

Если вас интересует любая гидроабразивная продукция от Win-Win Поставщик гидроабразивной резки, Свяжитесь со мной, пожалуйста.

В видео ниже показан наш новый заказ на два усилительных насоса SL-VI (50 л.с.) 60000 фунтов/кв. дюйм гидроабразивная резка При тестировании, упаковка к отгружению: