Описание

Детали гидроабразивных ячеек для роботов

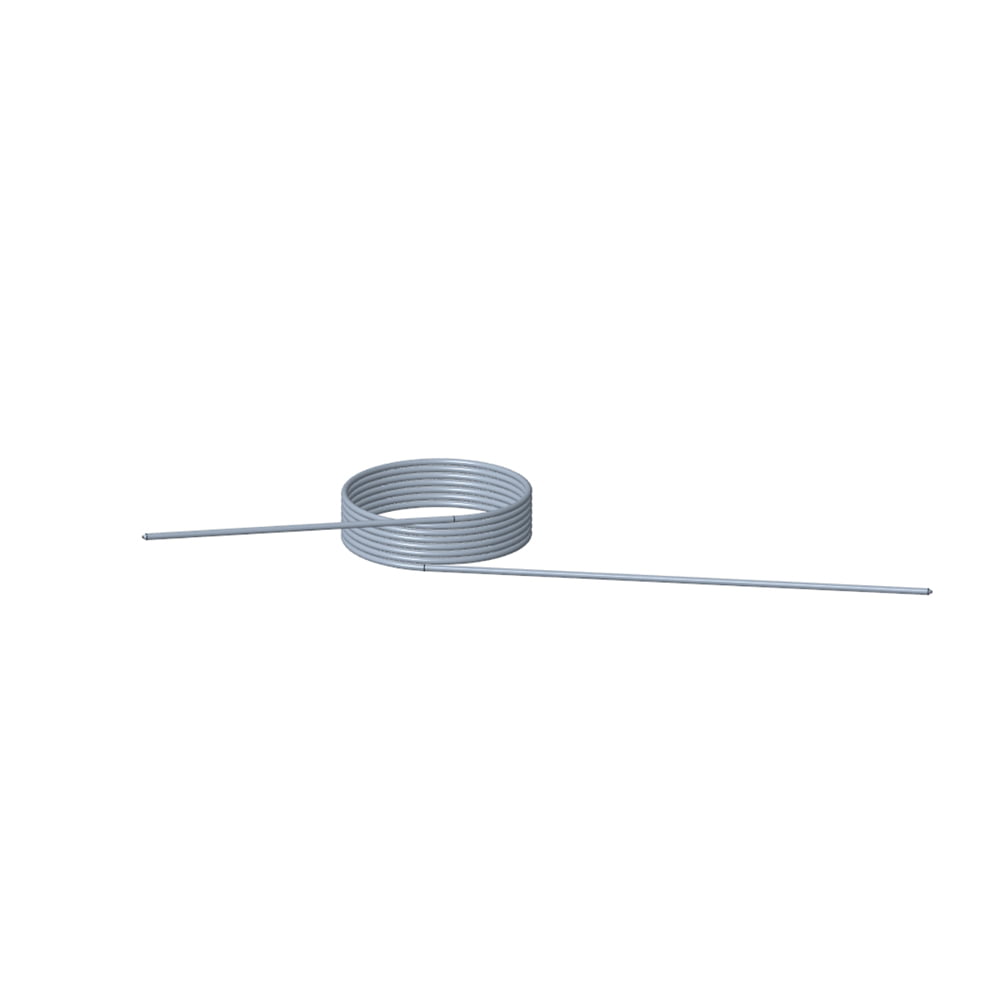

Item number: 303001 Coil Axis 2 IRB 4400

Подробностьs: используется на манипуляторах роботов ABB

Win-Win предоставляет решения для гидроабразивной резки роботов, детали ячеек для гидроабразивной резки роботов и т. Д.

Related robot waterjet cutting workstation & Детали гидроабразивной ячейки робота:

Роботизированный Система гидроабразивной резки & Детали гидроабразивных ячеек для роботов: Yaskawa robotic waterjet workstation and Robot Waterjet Cell Parts, Dual Fanuc robotic waterjet workstation and robot waterjet cell parts , ABB robotic waterjet workstation and robot waterjet cell parts.

FAQ of platform waterjet machine & robot waterjet system & Детали гидроабразивной ячейки робота:

How are the coils coiled for a robotic water jet cutting machine?

The process of coiling coils for robotic water jet cutting machines typically involves the following steps:

Design: First, a design drawing of the coiled tubing is created using computer-aided design (CAD) software based on the desired specifications and requirements. The design drawing should include information such as the size, shape, bend radius, and wall thickness of the coil.

Material Preparation: Select suitable metal materials for coiling. The common material is stainless steel, to ensure that the quality and size of the material meet the design requirements.

Bending mold making: According to the bending radius and shape in the design drawings, make a bending mold suitable for the coiled pipe of the robotic water jet cutting machine. The molds are usually made of metal to ensure that the coils are coiled to the required bend shape.

Coiling operation: The prepared metal material is mounted on the table of the robotic water jet cutting machine. The robotic water jet cutting machine is equipped with a water jet cutting head and a numerical control system. According to the dimensions and bending requirements in the design drawings, the robot’s movements are programmed and controlled by the CNC system.

Bending process: The water jet cutting head of the robotic water jet cutting machine cuts a portion of the metal material to deform it into a curved shape by spraying high-pressure water and abrasive. The robot’s movements control the bending angle and bending radius of the coils.

Inspection and Trimming: After completing the coiling, the coiled coils are inspected to ensure that their size, shape and quality meet the requirements. If necessary, it can be trimmed and repaired.

In conclusion, the coiled tubes of the robotic water jet cutting machine are bent and processed through the action of the robot and the water jet cutting technology. With the aid of precise CNC programming and bending molds, coiled tubes can be produced to meet design requirements.