Описание

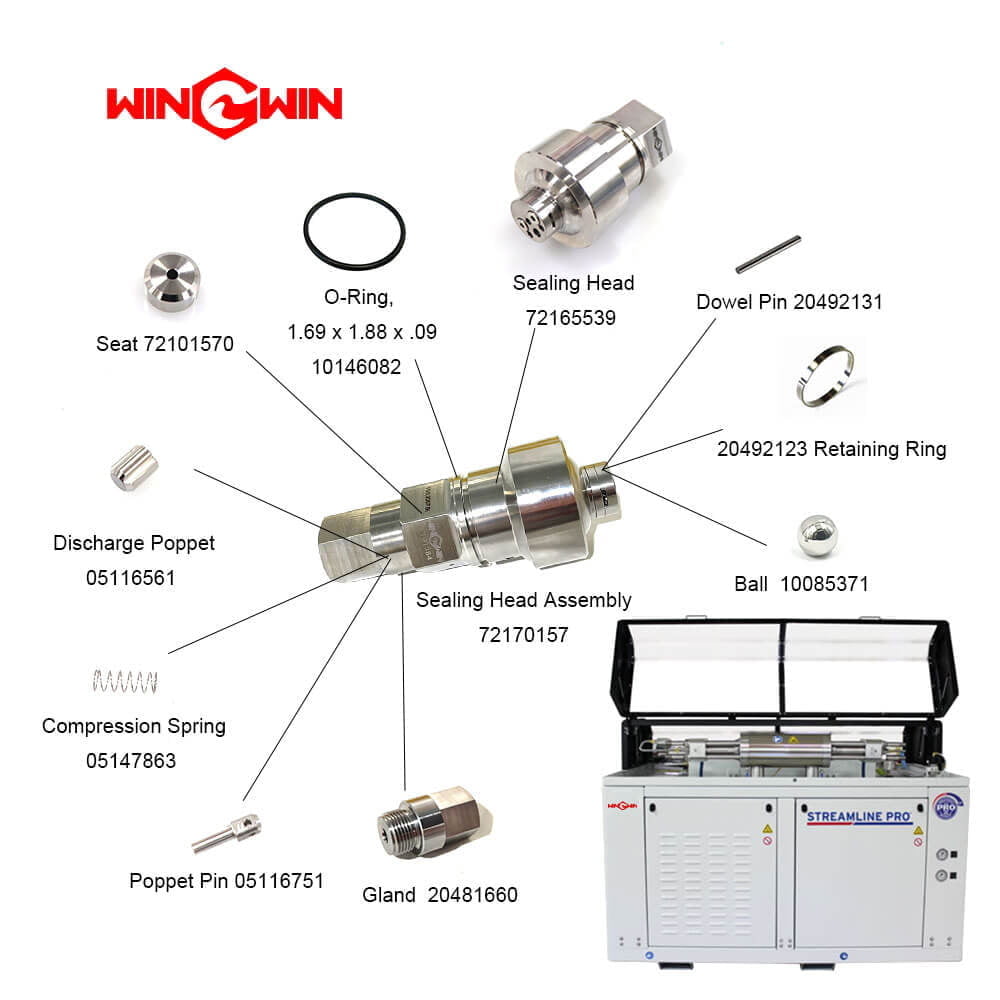

Hydrojet Cutter Spare Parts: Ball 10085371

The ball 10085371 is a specific type of ball that is used in 90,000 psi hydrojet cutter pumps.

Balls are used in pumps to control the flow of fluid, such as hydraulic oil or water, through the pump’s hydraulic system.

Пункт | Номер детали | Описание | Количество | Пункт | Номер детали | Описание | Количество |

1 | 05146592 | Прокладка, опора Topworks | 2 | 14 | 72162253 | Вантуз | 2 |

2 | 20476377 | Поддержка, Topworks | 2 | 15 | 05130091 | Картридж гидравлического уплотнения | 2 |

3 | 10118206 | Уплотнительное кольцо, 1,31×1,56× .13 | 2 | 16 | 72175989 | Фланец фиксатора втулки | 2 |

4 | 05144514 | Гидравлический цилиндр | 1 | 17 | 72158494 | Узел уплотнения UHP | 2 |

5 | 05098991 | Винт с торцевой головкой, 3/8-16×3-3/4 | 8 | 18 | 72166738 | Цилиндр UHP | 2 |

6 | 95688743 | Стопорная шайба, .38 | 8 | 19 | 72163802 | Лайнер | 2 |

7 | 72101190 | Поршень в сборе | 1 | 20 | 20474325 | Шпилька, 1-1/8-12×18.31 | 8 |

8 | 10074771 | Уплотнительное кольцо, 5,25×5,50× .13 | 2 | 21 | 72170157 | Уплотнительная головка в сборе | 2 |

9 | 05120092 | Резервное кольцо, 5.25×5.50×.13 | 2 | 22 | 72178493 | Сборка фланца | 2 |

10 | 72175997 | Гидравлическая головка блока цилиндров | 2 | 23 | 20464590 | Плоская шайба, 1.13 | 8 |

11 | 05097886 | Винт с торцевой головкой, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Шестигранная гайка, 1-1/8-12 | 8 |

12 | 05144183 | Распорка в сборе, бесконтактный выключатель | 2 | 25 | 20489339 | Адаптер, JIC/труба, 50×.38 | 1 |

05144191 | Уплотнительное кольцо, .69×.88×.09 | 26 | 72176756 | Уплотнительное кольцо, 3,88×4,25× .19 | 6 | ||

13 | 72141569 | Комплект, бесконтактный выключатель | 2 | ||||

| 72134224 | Бесконтактный переключатель | ||||||

95119012 | Винт с торцевой головкой, 1/4-20×1 |

1. Types of balls

There are different types of balls used in high-pressure hydrojet cutter pumps, including check balls, poppet balls, and valve balls.

Each type of ball is designed to serve a specific function in the hydrojet cutter system, such as controlling the flow of fluid or preventing backflow.

2. Material composition

Balls used in high-pressure hydrojet cutter pumps are typically made from high-strength materials.

Materials: hardened steel or other alloys that can withstand the high pressures and vibration of the pump.

3. Size and dimensions

The ball 10085371 has a specific size and dimension, with a diameter of 0.1875 inches.

This size is designed to fit specific components of the hydrojet cutter pump, such as the check valve or poppet.

4. Pressure rating

Balls used in 90,000 psi hydrojet cutter pumps need to be able to withstand the high pressure of the water and hydraulic fluid in the pump.

The pressure rating of a ball refers to the maximum pressure it can withstand without failing or becoming dislodged.

5. Wear resistance

Balls used in high-pressure hydrojet cutter pumps can experience wear over time, particularly if they are exposed to high pressures or abrasive fluids.

It’s important to choose balls that are highly wear-resistant to ensure optimal performance and prevent leaks or other issues.

6. Surface finish

The surface finish of a ball used in a 90,000 psi hydrojet cutter pump can affect its performance and durability.

Balls with a smooth surface finish can help improve sealing and reduce wear, while rough or pitted surfaces can lead to leaks or other issues.

7. Corrosion resistance

Balls used in high-pressure hydrojet cutter pumps may be exposed to various fluids or chemicals that can cause corrosion or damage over time.

It’s important to choose balls that are highly corrosion-resistant to ensure optimal performance and prevent leaks or other issues.

8. Compatibility

Balls used in 90,000 psi hydrojet cutter pumps should be compatible with the specific fluids or chemicals used in the pump, as well as with the materials of the pump components.

It’s important to choose balls that are designed for use in high-pressure hydraulic systems and that are compatible with the specific fluids and materials used in your pump.

9. Replacement frequency

The frequency with which balls in a 90,000 psi hydrojet cutter pump need to be replaced can vary depending on several factors, such as the specific application, operating conditions, and maintenance practices.

As a general guideline, it’s a good idea to inspect balls regularly and replace them if any signs of wear or damage are noted.

Contact us for assistance.