Описание

The Ram Piston 72101205 is a component of hydraulic piston assembly used in Гидроабразивный насос 90 000 фунтов на квадратный дюйм.

This high pressure is necessary for cutting through harder and thicker materials, and the Ram Piston is designed to withstand the forces involved in generating such high pressures.

The Ram Piston is an essential component of hydraulic piston assembly in the pump that helps to create the high-pressure water flow necessary for cutting through a wide range of materials.

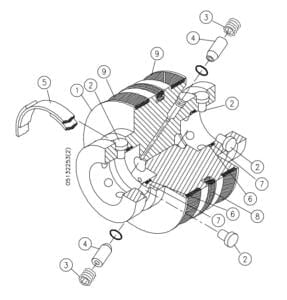

Пункт | Номер детали | Описание | Количество |

1 | 72101205 | Поршень Тарана, 5.50 | 1 |

2 | 05074380 | Булавка Clevis | 12 |

3 | 05049887 | Установочный винт | 2 |

4 | 10148757 | Обратный клапан в сборе | 2 |

5 | 05088364 | Стопорное кольцо | 2 |

6 | 05049994 | Опорное кольцо, 1,50 x 1,75 | 2 |

7 | 05087713 | Уплотнительное кольцо, 1,25 x 1,50 x .13 | 2 |

8 | 05120118 | Уплотнительная сборка | 1 |

9 | 05120100 | Подшипник | 2 |

| 72168337 | Комплект запасных частей | ||

| Включает элементы 4, 5, 6, 7, 8 и 9 |

The specific dimensions of the Ram Piston 72101205 are 5.50 inches (139.7 mm) in diameter and 4.50 inches (114.3 mm) in length.

The Ram Piston is typically made from a high-strength metal alloy, such as stainless steel or titanium, that is able to withstand the extreme pressures and forces involved in generating the waterjet.

It is designed to be precision-machined to ensure that it moves back and forth smoothly and accurately within the hydraulic piston assembly, which is critical for maintaining the performance and accuracy of the waterjet cutting process.

If you are in need of a replacement Ram Piston for your 90,000 psi waterjet pump, it is important to ensure that you are using a high-quality component that meets the specifications of the manufacturer.

Using an incorrect or low-quality Ram Piston can result in decreased performance, increased wear and tear on the pump, and even safety issues.

Its proper functioning is essential for the performance and safety of the machine.

Q: What are some signs that my Ram Piston of hydraulic piston assembly may be malfunctioning?

A: There are several signs that can indicate that the Ram Piston of hydraulic piston assembly may be malfunctioning. Here are a few examples:

1. Reduced performance

If your waterjet cutting machine is taking longer than usual to cut through materials or is not cutting through materials at all, it could be a sign that the Ram Piston is not functioning properly.

This may be caused by reduced water pressure or slower movement of the piston within the hydraulic piston assembly.

2. Unusual sounds

If you hear unusual sounds coming from your waterjet cutting machine, such as banging or clanging, it could be a sign that the Ram Piston is malfunctioning.

This may be due to the piston striking other components in the hydraulic system or due to other issues with the machinery.

3. Утечка

If you notice water or other fluids leaking from your waterjet cutting machine, it could be a sign that the Ram Piston or other components in the hydraulic system are damaged or worn.

This can pose a safety hazard and should be addressed as soon as possible.

4. Overheating

If you notice that your waterjet cutting machine is overheating, it could be a sign that the Ram Piston is damaged or worn.

This may be due to the piston not moving smoothly within the hydraulic piston assembly or due to other issues with the machinery.

5. Vibration

If you feel excessive vibration or shaking in your waterjet cutting machine, it could be a sign that the Ram Piston or other components in the hydraulic system are damaged or worn.

This can be caused by the piston not moving smoothly within the hydraulic piston assembly or by other issues with the machinery.

6. Visual damage

If you inspect the hydraulic cylinder and Ram Piston and notice visible signs of damage, such as cracks, dents, or wear, it is likely that the piston is damaged and needs to be repaired or replaced.

7. Unusual hydraulic fluid color or odor

If the hydraulic fluid in your waterjet cutting machine is discolored or has an unusual odor, it could be a sign of contamination or other issues with the hydraulic system.

This can cause damage to the Ram Piston and other components in the system over time.

8. Difficulty with startup

If it takes longer than usual for your waterjet cutting machine to start up or if it has difficulty building pressure, it could be a sign that the Ram Piston is damaged or worn.

This can be caused by issues such as wear and tear, contamination, or damage to other components in the hydraulic system.

If you notice any of these signs, it is important to have your waterjet cutting machine inspected by a qualified technician as soon as possible.

Ignoring these signs can lead to further damage to the machinery and potentially pose a safety hazard.

A qualified technician can diagnose the issue and determine if the Ram Piston or other components need to be repaired or replaced.

Regular maintenance and inspection of your waterjet cutting machine can help to prevent these issues from occurring in the first place and ensure that your machine operates safely and effectively.

Q: What are some common causes of Ram Piston of hydraulic piston assembly damage?

A: Here are a few factors that can contribute to damage or failure of the Ram Piston:

1. Wear and tear

Over time, the constant movement of the Ram Piston within the hydraulic piston assembly can cause wear and tear on the piston and other components in the hydraulic system.

This can cause the piston to become damaged or worn, which can affect its performance and potentially lead to failure.

2. Contamination

Contamination of the hydraulic fluid can cause damage to the Ram Piston and other components in the hydraulic system.

Contaminants such as dirt, dust, and other particles can cause abrasion and wear on the piston and other components, eventually leading to damage or failure.

3. Overpressure

If the water pressure generated by the waterjet cutting machine exceeds the design specifications of the Ram Piston, it can cause the piston to become damaged or fail.

This can be caused by a variety of factors, such as a malfunctioning relief valve or other issues with the hydraulic system.

4. Improper installation

If the Ram Piston is not installed correctly or is not compatible with the hydraulic piston assembly or other components, it can cause damage to the the hydraulic system.

This can result in reduced performance and potentially pose a safety hazard.

5. Impact damage

If the Ram Piston is struck by other components in the hydraulic system or by external objects, it can cause damage to the piston.

6. Improper use

Misuse or improper operation of the waterjet cutting machine can cause damage to the Ram Piston and other components.

For example, running the machine at too high of a pressure or cutting materials that are too thick or hard can place excessive strain on the hydraulic system, causing damage to the hydraulic piston assembly.

7. Lack of lubrication

The Ram Piston and other components in the hydraulic system require proper lubrication to function smoothly and effectively.

If the hydraulic fluid is not properly lubricated or if the lubricant is low quality, it can cause excessive wear and tear on the Ram Piston, leading to damage or failure.

8. Environmental factors

The environment in which the waterjet cutting machine is operated can also contribute to damage or failure of the Ram Piston.

Exposure to extreme temperatures, humidity, and corrosive substances can cause corrosion, wear, and other damage to the hydraulic system and its components.

9. Age and use

Over time, the Ram Piston and other components in the hydraulic system will naturally deteriorate due to age and use.

Regular maintenance and inspection can help to identify and address potential issues before they become major problems.

Q: How often should I inspect the Ram Piston of hydraulic piston assembly?

A: The Ram Piston in a high-quality waterjet cutting machine can last for several years with proper maintenance and care.

The frequency of Ram Piston inspection of hydraulic piston assembly can vary depending on several factors, such as the age of the machine, the frequency of use, and the operating conditions.

As a general guideline, it is recommended that the Ram Piston of hydraulic piston assembly be inspected at least once a year, or more frequently if the machine is used heavily.

Q: Are there any other components I should be careful about when replacing the Ram Piston?

A: When replacing the Ram Piston of hydraulic piston assembly, there are several other components that you should be careful about:

1. Hydraulic cylinder

The hydraulic cylinder is the component that houses the Ram Piston and is responsible for moving the piston back and forth.

When replacing the Ram Piston, inspect the hydraulic cylinder for signs of cracks or scoring.

2. Seals and gaskets

The seals and gaskets in the hydraulic system help to prevent leaks and maintain pressure.

3. Relief valve

The relief valve in the hydraulic system helps to regulate pressure and prevent damage to the Ram Piston and other components.

When replacing the Ram Piston, inspect the relief valve for proper operation.

4. Filters

The filters in the hydraulic system help to prevent contamination of the hydraulic fluid, which can cause damage to the Ram Piston and other components.

When replacing the Ram Piston, inspect the filters to maintain the cleanliness of the hydraulic fluid.

5. Mounting hardware

The mounting hardware for the Ram Piston and other components in the hydraulic system should be inspected for signs of wear or damage when replacing the Ram Piston.

It is important to ensure that the mounting hardware is tightened to the manufacturer’s specifications to prevent damage to the Ram Piston and other components.

6. Control valves

The control valves in the hydraulic system help to regulate the flow of fluid and pressure.

When replacing the Ram Piston, it is important to inspect the control valves for proper operation.

7. Hoses and fittings

The hoses and fittings in the hydraulic system connect the various components and help to ensure proper fluid flow.

Любые другие требования к гидравлической поршневой сборке или гидроабразивному насосу 90 000 фунтов на квадратный дюйм, пожалуйста, Свяжитесь с нами.