Описание

The Check Valve Assembly 10148757 is a component of hydraulic piston assembly used in the Гидроабразивный насос 90 000 фунтов на квадратный дюйм.

Specifically, the check valve assembly is a one-way valve that allows water to flow through the pump in one direction only, preventing backflow and maintaining pressure in the hydraulic system.

This helps to ensure safe and effective operation of the waterjet pump.

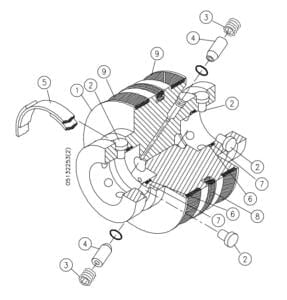

Пункт | Номер детали | Описание | Количество |

1 | 72101205 | Поршень Тарана, 5.50 | 1 |

2 | 05074380 | Булавка Clevis | 12 |

3 | 05049887 | Установочный винт | 2 |

4 | 10148757 | Обратный клапан в сборе | 2 |

5 | 05088364 | Стопорное кольцо | 2 |

6 | 05049994 | Опорное кольцо, 1,50 x 1,75 | 2 |

7 | 05087713 | Уплотнительное кольцо, 1,25 x 1,50 x .13 | 2 |

8 | 05120118 | Уплотнительная сборка | 1 |

9 | 05120100 | Подшипник | 2 |

| 72168337 | Комплект запасных частей | ||

| Включает элементы 4, 5, 6, 7, 8 и 9 |

The check valve assembly of hydraulic piston assembly includes a valve body, spring, and ball that work together to control the flow of water.

The valve body contains a seat where the ball rests when the pump is not in use.

When the pump is in operation, water flows through the valve body and pushes the ball away from the seat, allowing water to flow through the pump.

When the pump is turned off, the spring pushes the ball back onto the seat, preventing water from flowing back into the pump.

The check valve assembly is made of high-quality, durable materials like stainless steel or brass to ensure reliable and long-lasting performance.

It is designed to withstand the high pressures and stresses of the waterjet pump, and is manufactured to meet the required quality standards for safe and effective operation.

The pressure rating of the assembly is typically rated for pressures of up to 90,000 PSI or higher.

Proper installation of the check valve assembly is important to ensure safe and effective operation of the waterjet pump.

The assembly should be installed according to the manufacturer’s specifications and instructions, using the recommended torque specifications.

Regular cleaning of the check valve assembly of hydraulic piston assembly is important to ensure that it operates effectively.

The assembly can become clogged with debris or dirt over time, which can affect its ability to control the flow of water.

It is important to follow the manufacturer’s recommendations for cleaning the check valve assembly to ensure safe and effective operation of the waterjet pump.

Q: How can I inspect the check valve assembly of hydraulic piston assembly for wear and damage?

A: Inspecting the check valve assembly of hydraulic piston assembly for wear and damage is an important part of regular maintenance and can help to identify potential issues before they become major problems.

Here are some steps you can take to inspect the check valve assembly of hydraulic piston assembly:

1. Turn off the pump

Before inspecting the check valve assembly, it is important to turn off the waterjet pump and disconnect it from the power source to ensure safety.

2. Locate the check valve assembly

The check valve assembly of hydraulic piston assembly is usually located near the inlet of the hydraulic system of the waterjet pump.

It may be connected to a hose or other components of hydraulic piston assembly.

3. Inspect the exterior

Inspect the exterior of the check valve assembly for signs of wear or damage, such as cracks, corrosion, or other visible signs of wear.

Check the fittings and connections for signs of looseness or damage.

4. Remove the assembly

If necessary, remove the check valve assembly of hydraulic piston assembly from the hydraulic system to inspect it more closely.

Follow the manufacturer’s instructions for removing and reinstalling the assembly.

5. Inspect the interior

Inspect the interior of the check valve assembly for signs of wear or damage, such as cracks, corrosion, or other visible signs of wear.

Check the spring and ball for signs of wear or damage.

6. Clean the assembly

Clean the check valve assembly using an appropriate cleaning solution and technique, as recommended by the manufacturer.

Use a soft brush or cloth to gently remove dirt anddebris from the assembly, and then rinse with clean water to remove any remaining residue.

7. Check for proper function

Once the check valve assembly is clean, reassemble it and test it for proper function.

Check that the ball moves freely and that the spring is working properly.

Test the assembly to ensure that it is controlling the flow of water through the hydraulic system properly, and that it is maintaining pressure as expected.

8. Replace if necessary

If you notice any signs of wear or damage during the inspection, or if the check valve assembly is not functioning properly, it may need to be replaced.

Follow the manufacturer’s instructions for replacing the assembly, or contact their customer support for guidance.

Cleaning solution for the check valve assembly of hydraulic piston assembly:

As a general rule, it is best to use a cleaning solution that is compatible with the materials used in the check valve assembly and that is formulated for use with high-pressure hydraulic systems.

One option for cleaning the check valve assembly is to use a specialized hydraulic system cleaner, which is designed to remove dirt, debris, and other contaminants from the hydraulic system without damaging the components.

These cleaners are typically formulated to be non-corrosive and non-toxic, and are safe for use in high-pressure hydraulic systems.

Another option is to use a solution of water and mild soap or detergent to clean the check valve assembly.

This solution can be applied using a soft brush or cloth to gently remove dirt and debris from the assembly, and then rinsed with clean water to remove any remaining residue.

It is important to follow the manufacturer’s recommendations for cleaning the check valve assembly and to use the appropriate cleaning solution and technique for the specific materials used in the assembly.

Using the wrong cleaning solution or technique can damage the assembly and affect its performance.

If you are unsure about the appropriate cleaning solution or technique for the check valve assembly in your 90k waterjet pump, you can consult our manufacturer’s documentation or contact our customer support for guidance.

We can provide specific recommendations based on the pump model, operating conditions, and other factors to ensure safeand effective cleaning of the assembly.

Любые другие требования к гидравлической сборке поршня или Гидроабразивный насос 90 000 фунтов на квадратный дюймПожалуйста Свяжитесь с нами.