Описание

Свяжитесь с нами, чтобы получить каталог запчастей для гидроабразивной резки FLOW и прайс-лист

1. Гидроабразивные детали FLOW показать видео:

2. Нажмите на номер продукта в таблице ниже, чтобы узнать о деталях для гидроабразивной резки FLOW.

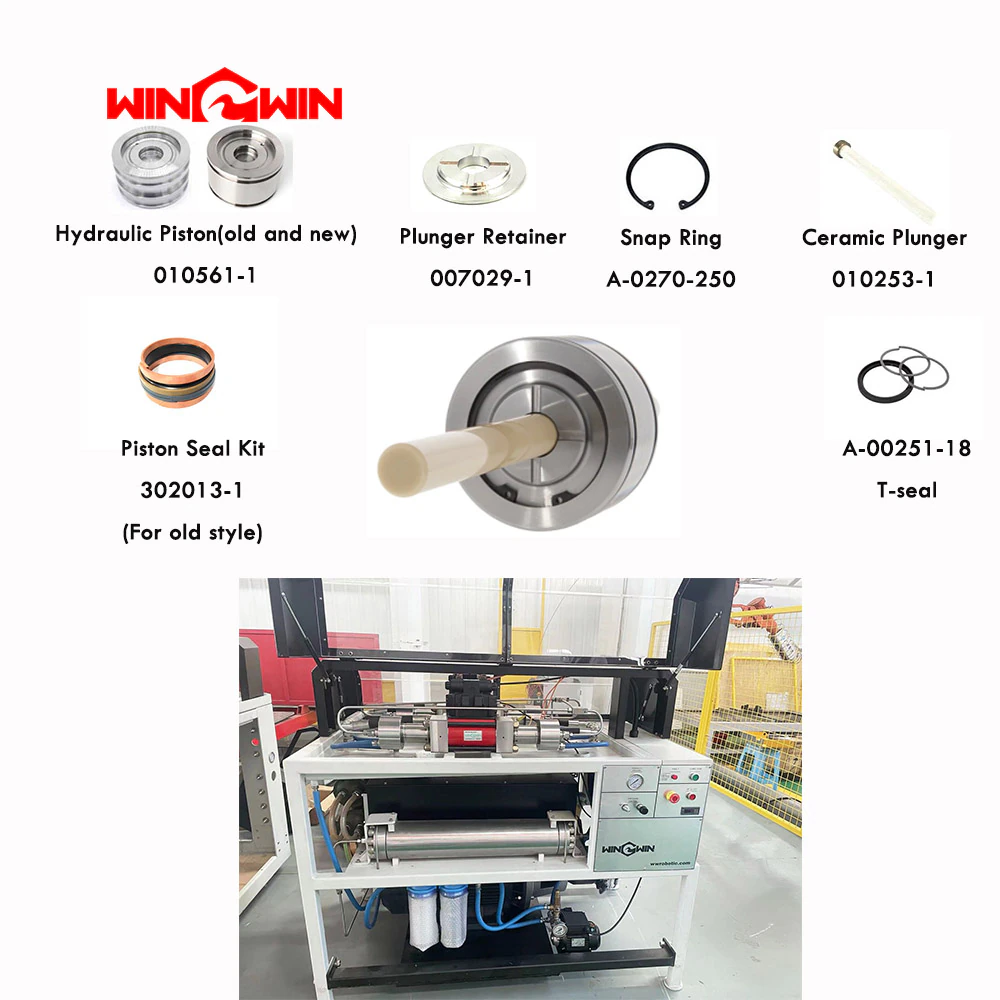

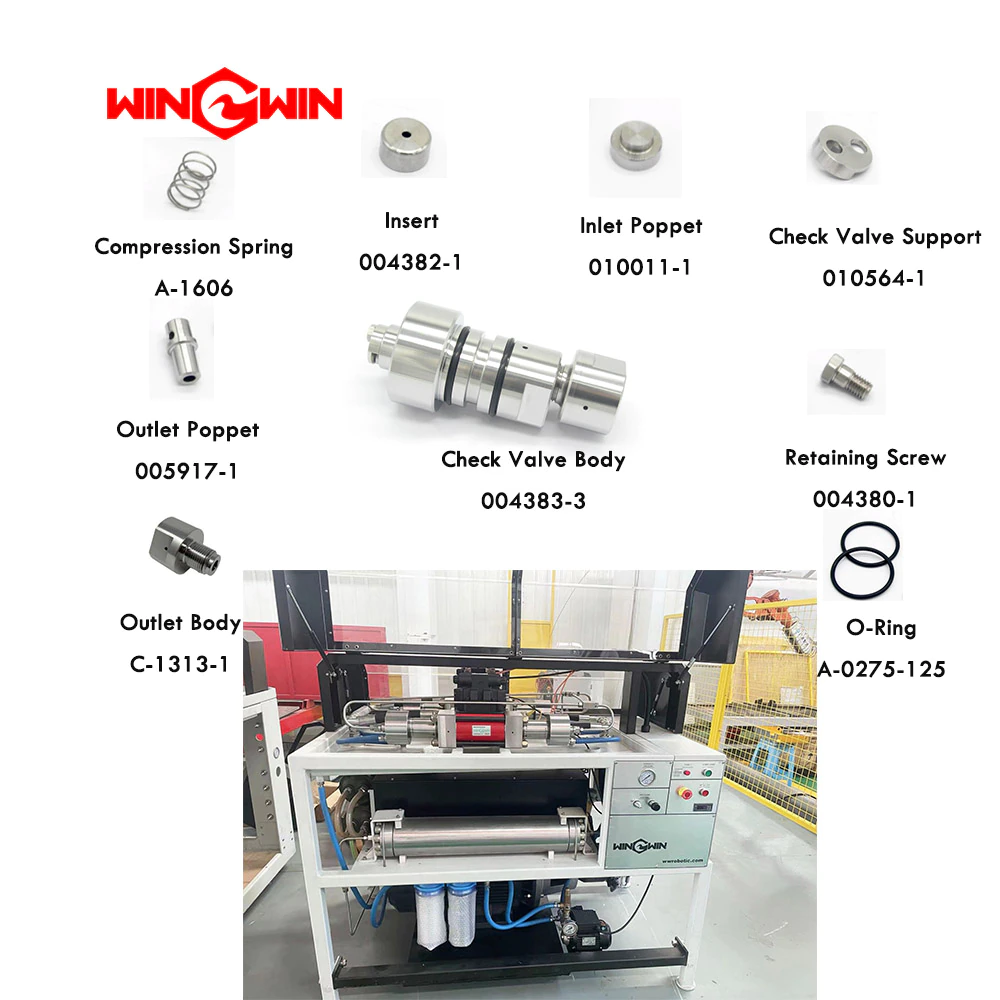

| Пункт | Номер продукта | Название продукта | Картина |

| 1 | 001198-1 | Комплект уплотнений высокого давления |  |

| 2 | 004383-3 | Корпус обратного клапана |  |

| 3 | 004694-1 | Ремкомплект спускного клапана |  |

| 4 | 007038-3 | Цилиндр высокого давления |  |

| 5 | 007303-1/2 | Концевой колокол |  |

| 6 | 010253-1 | Церемный поршень |  |

| 7 | 010642-1 | Ремкомплект обратного клапана |  |

| 8 | А-11275 | Уплотнение штока |  |

| 9 | 010558-3 | Узел усилителя |  |

Свяжитесь с нами для получения более полного каталога продукции или прайс-листа.

3. Видео о гидроабразивном насосе типа FLOW показывают:

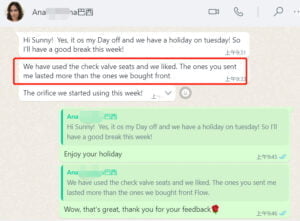

4. Отображение похвалы пользователя для приобретенных деталей для гидроабразивной резки FLOW:

5. Благодаря каждому клиенту, мы знаем друг друга в мире, такова судьба.

Поздоровайтесь, примите улыбку;

Скажите просьбу, получите помощь;

Выразить извинения, потерять заботу;

Поблагодарите и покажите стиль;

Попрощайтесь и оставьте возврат.

Нет ни шикарного языка, ни смелых слов,

Но моя благодарность вам не станет меньше.

6. Связанные вопросы о деталях гидроабразивной резки FLOW и станке гидроабразивной резки FLOW:

6.1 Связанные вопросы о деталях гидроабразивной резки FLOW и станке гидроабразивной резки FLOW:

Какие существуют типы компонентов гидроабразивной резки?

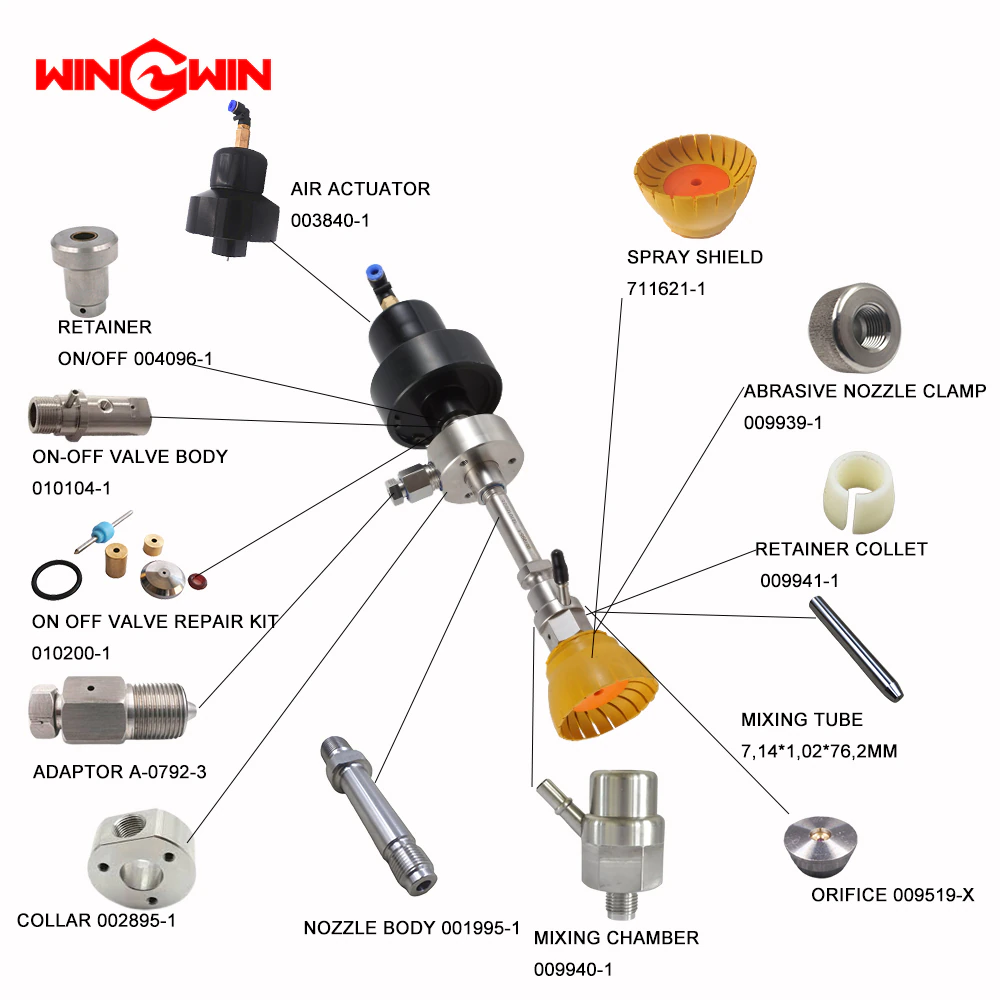

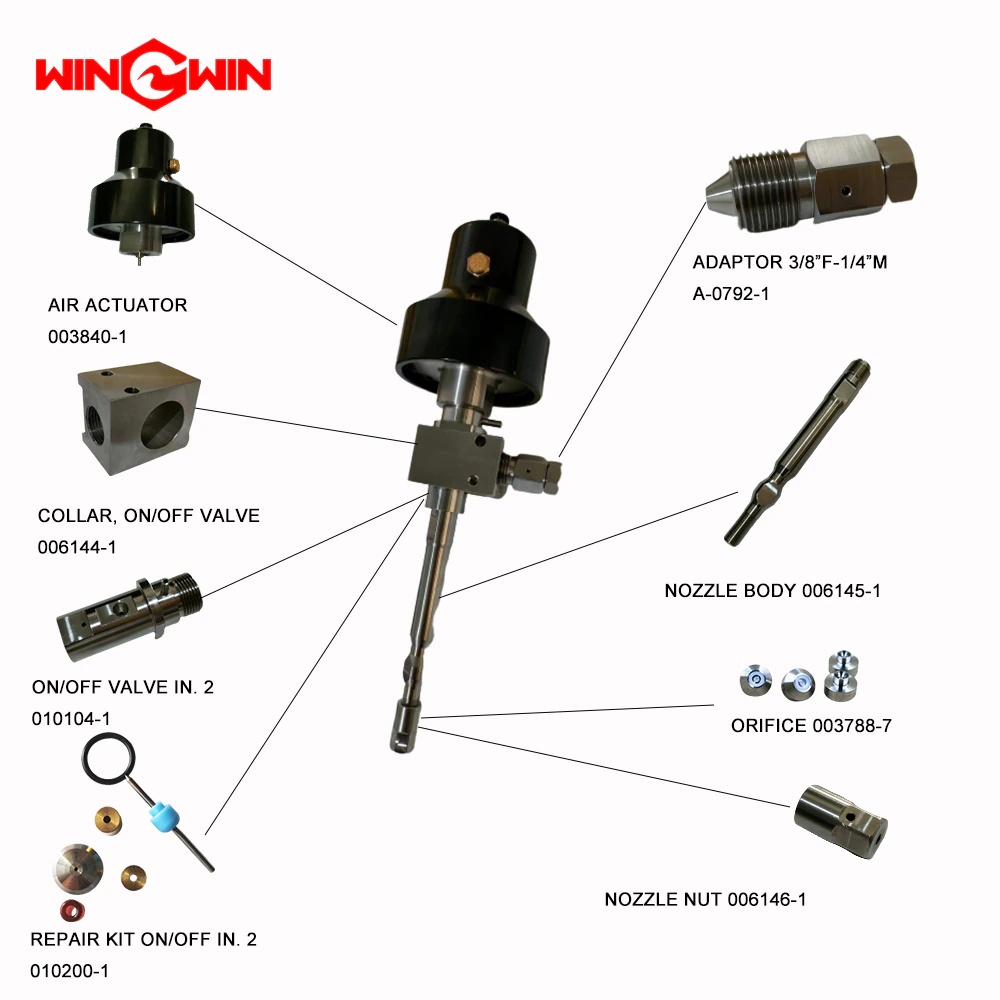

Детали станка гидроабразивной резки включают в себя детали режущей головки: в том числе режущую головку чистой воды, абразивную режущую головку, детали гидроабразивного насоса: включая детали гидравлического насоса, детали насоса с прямым приводом, детали электрического сервонасоса и т. Д.

Вспомогательные детали высокого давления для гидроабразивной резки: такие как колено, тройник, муфта, адаптер и т. Д.

Связанные расходные детали гидроабразивной резки Flow: такие как сопло гидроабразивных деталей, отверстие гидроабразивных деталей Flow, гидроабразивные детали Flow, гидроабразивные детали Flow, масляный фильтр, абразивное, гидравлическое масло и т. Д.

Связанные специальные инструменты гидроабразивных деталей Flow: гидроабразивные детали Flow цилиндрический ключ высокого давления, гидроабразивные детали Flow инструмент для уплотнения высокого давления, торцевой ключ для гидроабразивных деталей Flow, инструмент для нарезания резьбы и конуса трубок высокого давления Flow, гидроабразивные детали Flow blue goop, детали гидроабразивной резки Flow pure goop и т. Д.

6.2 Как выбрать подходящие детали для гидроабразивной резки Flow для моей области применения?

Выберите профессионального поставщика гидроабразивной резки с высоким качеством, высокой стабильностью, достаточным запасом, хорошим предпродажным, послепродажным обслуживанием и технической поддержкой.

6.3 Какие материалы обычно используются для изготовления деталей FLOW для гидроабразивной резки?

Использование специальной нержавеющей стали, высокой сжимаемости, материала с высокой износостойкостью, материала высокой твердости, специального материала для производства деталей с гидроабразивной обработкой

6.4 Как обслуживать и ремонтировать гидроабразивные детали FLOW?

Пользователи водоструйных машин должны пройти соответствующее обучение по эксплуатации и техническому обслуживанию машины перед использованием машины. Они могут быть обучены производителем или искать соответствующую информацию в Интернете, чтобы учиться, и их нельзя разбирать или ремонтировать вслепую.

6.5 Как устранить распространенные проблемы с компонентами гидроабразивной резки Flow?

Распространенными проблемами деталей FLOW для гидроабразивной резки являются: ремкомплект для включения/выключения клапана или ремкомплект для обратного клапана, износ или деформация ремонтного комплекта под высоким давлением, плохая герметизация и другие проблемы приводят к утечке воды или нестабильному давлению, нарушаются режущие работы, не забывайте регулярно заменять соответствующие детали.

6.6 Как установить и заменить детали гидроабразивной резки Flow?

Каждая гидроабразивная деталь Flow имеет соответствующую стандартную процедуру замены и процесс, а некоторые детали имеют специальные инструменты для установки, не работают по своему желанию, иначе возникнут ненужные неприятности, обратитесь к руководству или обратитесь к нам, мы ответим за вас.

6.7 Каковы преимущества использования компонентов расхода премиум-класса?

Преимущество изготовления высококачественных деталей для гидроабразивной резки заключается в том, что пользователи и друзья могут быть более спокойными. Мы знаем, что детали для гидроабразивной резки FLOW очень популярны в мире. Это универсальные и стандартизированные детали, и их легко купить на рынке, но качество низкое. Они неравномерны, что требует от нас эффективного их выявления. На то, чтобы опробовать их одну за другой, уйдет много времени и сил, поэтому мы стараемся не покупать слишком дешевые гидроабразивные детали Flow, чтобы избежать необходимых потерь, вызванных наступлением на яму.

Нам нужно выбирать качественные детали. Мы видим, что хотя стоимость покупки запчастей относительно высока, но

Это приносит массу соответствующих преимуществ. Например, качественные детали имеют длительный срок службы и менее частую замену, благодаря чему эффективность производства более гарантирована. Пользователи гидроабразивной резки знают, что время — деньги, особенно для компаний, которые обрабатывают некоторые высококачественные материалы, каждая секунда на счету, и это гонка со временем. Например, резка деталей интерьера автомобилей, аэрокосмического алюминия, корпуса скоростных катеров высокоскоростных железных дорог и других отраслях.

Поэтому подбираются качественные гидроабразивные детали Flow и повреждение определенной детали не вызовет даже повреждения смежных деталей, и частота замены хорошая, и количество разборок и монтажа меньше, что лучше защищает детали механизма и с меньшей вероятностью приведет к поломке.

6.8 Как гидроабразивные детали Flow отличаются от других типов режущих инструментов?

Детали станка гидроабразивной резки Flow уникальны и не могут быть заменены другими деталями машины, такими как фрезы, лазеры, плазма, ультразвук и т. Д. Их свойства, производительность, материалы и функции различны, поэтому их нельзя использовать универсально.

6.9 Как я могу оптимизировать процесс резки деталей Flow Waterjet?

Если вас не устраивает режущий эффект существующего станка гидроабразивной резки, то мы можем выяснить неудовлетворительные моменты, например, если вас не устраивает отделка резки, то мы можем поменять абразив, с 80 меш на 100 меш и 120 меш, с обычного качества, такого как речной песок, Морской песок до высокой твердости рудный песок.

Если вас не устраивает давление резки машины, мы можем модернизировать водоструйный насос высокого давления с 40k, 55k, 60k до 87k, 90k, 94k и т. Д. По сравнению с тем же материалом и толщиной, чем выше давление насоса, тем быстрее скорость резки.

Если вас не устраивает расход машины, мы можем заменить насос 3,8 л/мин на 6,5 л/мин, 7,6 л/мин и другие продукты.

Если вас не устраивает шум машины и вы чувствуете, что она слишком шумная, что скажется на вашем здоровье, настроении и окружающей среде, то вы можете рассмотреть возможность модернизации обычного трехфазного асинхронного двигателя до серводвигателя, при этом шум можно снизить более чем на 30%.

Если вас не устраивает срок службы деталей гидроабразивной резки машины Flow, рассмотрите возможность замены высококачественных деталей или обратитесь к нам, чтобы сделать модернизацию для вас

И предоставить соответствующие меры противодействия и подсказки.

Если вы считаете, что время использования режущей головки для рубиновых отверстий Flow слишком короткое, то у нас есть алмазное отверстие для гидроабразивных деталей Flow, которое не только имеет длительный срок службы, но и выгодную цену.

Если у вас есть старая машина и вы хотите ее модернизировать и отремонтировать, Win-Win также предлагает эту услугу

Если вы не разбираетесь в использовании и обслуживании машины, Win-Win также предоставляет техническую поддержку и обучение

6.91 Какие меры предосторожности следует соблюдать при работе с деталями Flow Waterjet?

Поскольку большинство деталей для гидроабразивной резки Гидроабразивные детали Flow изготовлены из толстой нержавеющей стали, они не только громоздкие, но и очень тяжелые. Мы должны уделять внимание защите рук и ног во время обращения и замены, чтобы не разбиться, а при замене некоторых деталей гидроабразивной резки Flow обязательно не забывайте отключать воду и электричество и не управляйте машиной во время ее работы, иначе это может привести к несчастному случаю с безопасностью.

6.92 Насколько точен станок гидроабразивной резки?

Точность станка гидроабразивной резки на самом деле хорошая. Его точность резки составляет плюс-минус 0,1 мм, что может почти удовлетворить требования к точности резки большинства материалов.

6.93 Каковы преимущества использования гидроабразивного резака?

Экономичность большинства станков гидроабразивной резки все еще довольно высока, за исключением некоторых отдельных брендов, они используют полностью электрические сервонасосы, а некоторые режущие платформы используют технологию магнитной левитации, эти затраты очень высоки, это зависит от пользователей, вложенных в производственный бюджет для покупки.

6.94 Чем гидроабразивные резаки отличаются от других типов режущих станков, таких как лазерные резаки?

Каждый из них имеет свои преимущества и недостатки, в зависимости от того, какой из них предпочитают пользователи.

Например, водная резка более экологична, чем холодная резка, но в дополнение к машине под давлением 90k, если машина под давлением 60k используется для резки материалов с высокой твердостью и высокой герметизацией, скорость относительно низкая.

Как и при лазерной резке, высокая скорость резки очень высока, но это приведет к тепловому повреждению или деформации, а также к дыму

Это зависит от того, какие материалы пользователям нужно резать, и какую точку выбрать, и выбрать ту, которая им подходит, а не самую дорогую.

7. My name is Sunny Li (the Director of International Trade Department), as the name suggests, I am a warm, positive and optimistic person. The following is my personal video: Love Life & Love Work.

8. Если у вас есть какие-либо вопросы о решениях для гидроабразивной резки или оборудовании для гидроабразивной резки, мы можем предоставить бесплатную техническую поддержку, Свяжитесь с нами, пожалуйста.