Описание

Знакомство

Waterjet machines are versatile tools used in various industries for cutting, shaping, and processing materials.

They rely on various waterjet machine parts, including O-ring 10074714, to ensure optimal performance and efficiency.

The following contents will discuss the features and benefits of O-ring 10074714 and its use in 90000 PSI waterjet machine applications.

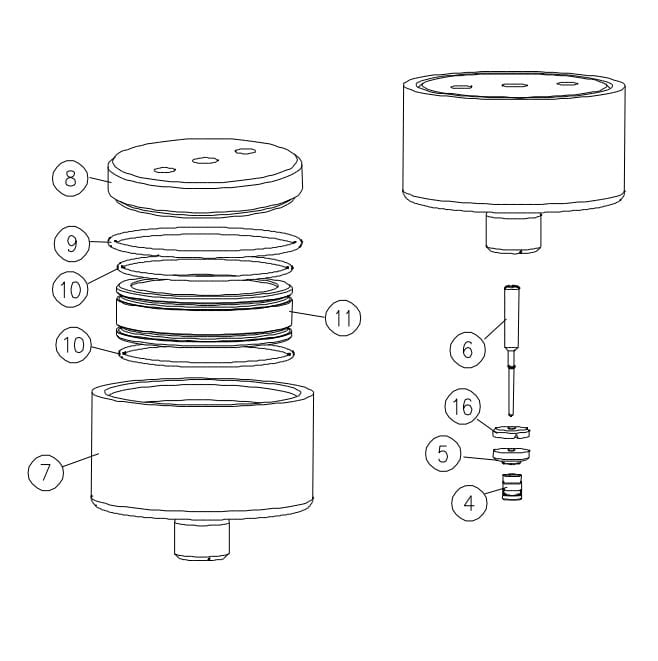

Item 9: 10074714 O-Ring, 2.44 x 2.63 x .09

Пункт | Номер детали | Описание | Количество | Пункт | Номер детали | Описание | Количество |

1 | 20468617 | Корпус клапана | 1 | 9 | 10074714 | Уплотнительное кольцо, 2,44 x 2,63 x 0,09 | 1 |

2 | 10178697 | Седло клапана | 1 | 10 | 10074565 | Уплотнительное кольцо, 2,25 x 2,38 x 0,06 | 2 |

3 | 20451557 | Адаптер UHP | 1 | 11 | BV501184 | Поршень | 1 |

4 | 72112069 | Уплотнительная сборка | 1 | 12 | 20452965 | Воротник UHP, .38 | 1 |

5 | 20475874 | Опорное кольцо, бронза | 1 | 13 | 20452956 | UHP Gland, .38 | 1 |

6 | 20475878 | Шток клапана | 1 | 14 | 20452959 | Воротник UHP, .25 | 1 |

7 | 20468601 | Пневматический цилиндр | 1 | 15 | 20452962 | UHP Gland, .25 | 1 |

8 | BV601184 | Крышка цилиндра | 1 | 16 | 20475882 | Опорное кольцо, SST | 1 |

| 20477518 | Комплект запасных частей | ||||||

| Включает пункты 2, 4, 5, 6, 9, 10 и 16 |

Features of O-Ring 10074714

O-ring 10074714 is made from nitrile rubber, which provides excellent resistance to oil, fuel, and other petroleum-based fluids.

This material is known for its high tensile strength, abrasion resistance, and durability, making it ideal for use in hydraulic and pneumatic systems in waterjet machines.

The black color of O-ring 10074714 indicates that it is made from nitrile rubber, according to the industry-standard color coding system.

Benefits of O-Ring 10074714 in 90000 PSI Waterjet Machine Applications

1. High-Pressure Resistance

Waterjet machines that operate at 90000 PSI require components that can withstand high pressure and stress.

O-ring 10074714 is designed to handle high-pressure applications, making it an ideal choice for use in 90000 PSI waterjet machines.

2. Resistance to Oil and Fuel

Nitrile rubber, the material used to make O-ring 10074714, is highly resistant to oil, fuel, and other petroleum-based fluids.

This makes it an excellent choice for use in waterjet machines that rely on hydraulic and pneumatic systems to operate.

The O-ring’s resistance to oil and fuel ensures that the machine’s components remain functional and efficient during operation, preventing downtime and costly repairs.

3. Durability

O-ring 10074714 is known for its high tensile strength and abrasion resistance, which makes it a durable component in waterjet machines.

It can withstand continuous use and exposure to harsh environments without compromising its performance.

The O-ring’s durability ensures that it can withstand the wear and tear caused by the machine’s high-pressure operations, reducing the need for frequent replacements and maintenance.

4. Cost-Effective

O-ring 10074714 is an affordable component that provides excellent value for its cost.

Its durability and resistance to oil and fuel make it a cost-effective choice for use in waterjet machines, reducing the need for frequent replacements and maintenance.

The O-ring’s cost-effectiveness ensures that businesses can minimize expenses associated with machine maintenance and operations, improving their bottom line.

Using O-Ring 10074714 in Waterjet Machine Applications

When using O-ring 10074714 in waterjet machine applications, proper installation and maintenance are essential.

Regular inspection of the O-ring and other components can prevent leakage and failure, which can result in costlydowntime.

Additionally, it is crucial to ensure that the O-ring is compatible with the machine’s operating environment to prevent swelling or other forms of damage.

Proper lubrication of O-ring 10074714 during installation can also prevent abrasion, pinching, or cutting of the O-ring.

Lubrication can decrease surface friction and prevent excessive wear and tear, extending the O-ring’s lifespan.

It is important to note that the lubricant used should be compatible with the O-ring material and the machine’s operating environment to prevent breakdown or damage.

Inspection and replacement of damaged O-rings are essential to prevent leakage and failure.

Signs of a damaged O-ring include blisters, pocks, or pits on the surface, small cuts or gashes, and a flat surface parallel to the direction of motion.

Regular inspection and replacement of damaged O-rings can prevent costly downtime and repairs, ensuring optimal performance and efficiency of the waterjet machine.

Compatibility with 90000 PSI Waterjet Machines

O-ring 10074714 is designed to handle high-pressure applications and is compatible with waterjet machines operating at 90000 PSI.

Its resistance to oil and fuel, durability, and affordability make it an excellent choice for hydraulic and pneumatic systems in high-pressure waterjet machines.

Proper installation, lubrication, and maintenance are essential for optimal performance and longevity.

Color Coding of O-Rings

The color coding of O-rings helps to identify the type of material used, preventing installation errors.

The black color of O-ring 10074714 indicates that it is made from nitrile rubber, which is highly resistant to oil and fuel.

The color coding system has become widely adopted, and it helps to ensure that the correct O-ring is used in the right application, minimizing errors and improving efficiency.

Thickness of O-Rings in Waterjet Machines

The thickness of an O-ring can impact its performance in dynamic applications.

A thicker O-ring has more cross-section to withstand movement and is less prone to rolling.

However, thicker seals can also generate more friction in dynamic applications.

The thickness of O-ring 10074714 is designed to provide optimal performance in hydraulic and pneumatic systems in waterjet machines.

Careful consideration should be given to the thickness of O-rings used in waterjet machines to ensure optimal performance and efficiency.

Swelling of O-Rings

O-rings can become damaged over time due to factors such as exposure to high temperatures, pressure changes, and physical damage during installation or use.

O-rings are also susceptible to swelling when exposed to certain chemicals or high humidity levels.

Excessive swelling can affect the O-ring’s performance and lead to leakage or failure.

It is important to select the correct material for the application and ensure that it is compatible with the surrounding environment.

O-ring 10074714 is made from nitrile rubber, which is resistant to swelling and is an ideal choice for waterjet machines operating in harsh environments.

Заключение

In conclusion,O-ring 10074714 is a vital component in waterjet machines operating at 90000 PSI.

Its resistance to high pressure, oil, and fuel, along with its durability and affordability, make it a cost-effective choice for use in hydraulic and pneumatic systems.

Proper installation, maintenance, and lubrication can help to ensure optimal performance and longevity, while regular inspection and replacement of damaged O-rings can prevent leakage and failure.

The color coding system of O-rings helps to prevent installation errors, and selecting the appropriate thickness and material for the specific application is crucial for optimal performance.

The eight pieces of information provided by the user have been integrated throughout the content to provide a comprehensive understanding of O-ring 10074714 and its use in 90000 PSI waterjet machine applications.

At Win-Win, we offer a wide range of waterjet machine parts, including O-ring 10074714, to meet the needs of various industries.

Our products are of the highest quality and are designed to provide optimal performance and efficiency in waterjet machines operating at 90000 PSI.

Contact us to learn more about our products and how we can support your waterjet machine needs.