Описание

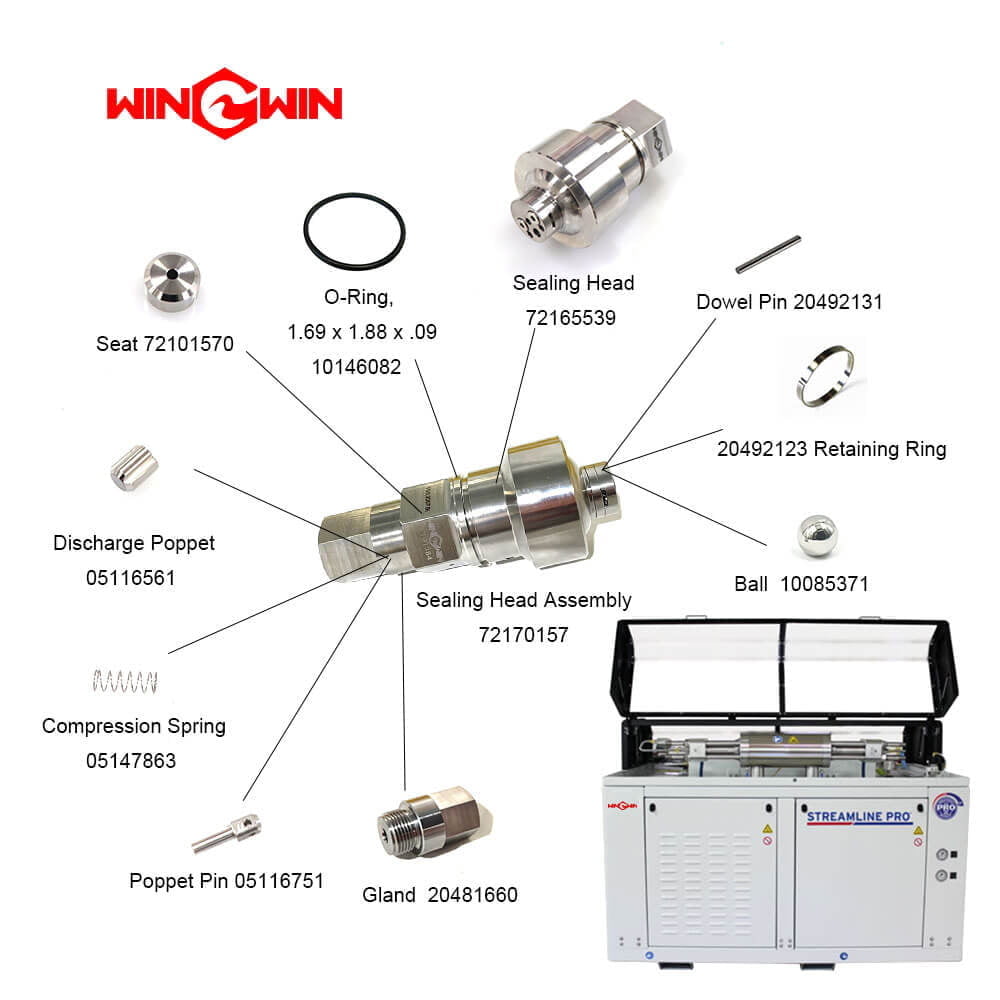

Discharge poppet 05116561 is one of 90000 psi parts produced by Win-Win Waterjet.

Пункт | Номер детали | Описание | Количество | Пункт | Номер детали | Описание | Количество |

1 | 05146592 | Прокладка, опора Topworks | 2 | 14 | 72162253 | Вантуз | 2 |

2 | 20476377 | Поддержка, Topworks | 2 | 15 | 05130091 | Картридж гидравлического уплотнения | 2 |

3 | 10118206 | Уплотнительное кольцо, 1,31×1,56× .13 | 2 | 16 | 72175989 | Фланец фиксатора втулки | 2 |

4 | 05144514 | Гидравлический цилиндр | 1 | 17 | 72158494 | Узел уплотнения UHP | 2 |

5 | 05098991 | Винт с торцевой головкой, 3/8-16×3-3/4 | 8 | 18 | 72166738 | Цилиндр UHP | 2 |

6 | 95688743 | Стопорная шайба, .38 | 8 | 19 | 72163802 | Лайнер | 2 |

7 | 72101190 | Поршень в сборе | 1 | 20 | 20474325 | Шпилька, 1-1/8-12×18.31 | 8 |

8 | 10074771 | Уплотнительное кольцо, 5,25×5,50× .13 | 2 | 21 | 72170157 | Уплотнительная головка в сборе | 2 |

9 | 05120092 | Резервное кольцо, 5.25×5.50×.13 | 2 | 22 | 72178493 | Сборка фланца | 2 |

10 | 72175997 | Гидравлическая головка блока цилиндров | 2 | 23 | 20464590 | Плоская шайба, 1.13 | 8 |

11 | 05097886 | Винт с торцевой головкой, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Шестигранная гайка, 1-1/8-12 | 8 |

12 | 05144183 | Распорка в сборе, бесконтактный выключатель | 2 | 25 | 20489339 | Адаптер, JIC/труба, 50×.38 | 1 |

05144191 | Уплотнительное кольцо, .69×.88×.09 | 26 | 72176756 | Уплотнительное кольцо, 3,88×4,25× .19 | 6 | ||

13 | 72141569 | Комплект, бесконтактный выключатель | 2 | ||||

| 72134224 | Бесконтактный переключатель | ||||||

95119012 | Винт с торцевой головкой, 1/4-20×1 |

In the 90000 psi parts of waterjet pump, the discharge poppet is a critical part of the system, as it helps to regulate the flow of water and ensure that the pressure remains consistent.

To operate effectively, the discharge poppet is typically made of a hard, durable material, such as tungsten carbide, and is designed to withstand the high pressures and abrasive nature of the waterjet stream.

The poppet is typically located at the outlet of the pump, where it controls the flow of water into the high-pressure hose. The poppet is typically controlled by a hydraulic or pneumatic system that adjusts the pressure on the poppet spring, allowing for precise control over the water flow.

When the pump is activated, water is forced into the poppet, which is held closed by a spring or other mechanism. As the pressure builds, the poppet begins to open, allowing water to flow through and into the high-pressure hose.

The poppet is designed to open and close rapidly, allowing the pump to maintain a consistent flow and pressure.

In addition to regulating pressure and flow, the discharge poppet also serves as a safety feature to protect the pump from damage.

When the pressure in the system exceeds a certain threshold, the poppet will open to release excess pressure and prevent damage to the pump or other components.

This is known as a pressure relief valve, and it is a critical safety mechanism in 90000 psi parts of waterjet systems.

What are some common issues that can arise with the discharge poppet in 90000 psi parts of a waterjet pump?

1. Poppet wear

Over time, the high-pressure water stream can cause wear on the poppet, particularly on the sealing surfaces. This can result in leakage, which can reduce the efficiency of the pump and cause other issues.

To address this, the poppet may need to be replaced or refurbished. Poppet refurbishment typically involves machining or lapping the sealing surfaces to restore them to their original condition. In some cases, the poppet may need to be replaced entirely if the wear is too severe.

2. Spring failure

The poppet is held closed by a spring, and if this spring fails or loses tension, the poppet may not close properly, resulting in reduced pressure or flow. This can be due to fatigue or other factors, and may require replacement of the spring or the entire poppet assembly in 90000 psi parts.

3. Contamination

If debris or other foreign matter gets into the poppet assembly, it can cause the poppet to stick or cause damage to the seating surfaces. This can result in reduced efficiency or complete failure of the poppet.

4. Improper adjustment

The pressure on the poppet spring must be properly adjusted to ensure that the poppet opens and closes at the correct pressure. If the adjustment is incorrect, the pump may not operate at the desired pressure or flow rate.

5. Overpressure

In some cases, the pressure in the system may exceed the maximum rated pressure for the poppet or other components. This can cause damage to the poppet, resulting in leakage or complete failure.

Installing proper pressure monitoring and safety mechanisms, such as pressure relief valves and burst discs, can help prevent this issue.

What are some signs that the discharge poppet in 90000 psi parts needs to be replaced?

1. Утечки

If you notice water leaking from the poppet assembly, this is a clear indication that the poppet is not sealing properly. This can be due to wear on the sealing surfaces or other damage to the poppet assembly.

2. Reduced pressure or flow

If you notice a decrease in the pressure or flow rate of the waterjet stream, this may be due to a problem with the poppet.

Reduced pressure or flow can be caused by wear on the poppet or other issues that prevent the poppet from opening and closing properly.

3. Damage to the poppet

If you notice visible damage to the poppet, such as cracks or chips, this is a clear indication that the poppet needs to be replaced.

Damage to the poppet can cause leaks or other issues that can compromise the efficiency and safety of 90000 psi parts in waterjet system.

4. Poppet sticking

If the poppet becomes stuck in the closed position, this can prevent water from flowing through the system and cause a loss of pressure or flow. This can be due to wear or contamination in the poppet assembly.

5. Unusual noises

If you hear unusual noises coming from the pump or poppet assembly, this may be a sign of a problem with the poppet. Unusual noises can be caused by wear, damage, or other issues with the poppet assembly.

6. Poppet spring failure

If the poppet spring fails or loses tension, the poppet may not close properly, resulting in reduced pressure or flow. This can be due to fatigue or other factors, and may require replacement of the spring or the entire poppet assembly in 90000 psi parts.

If you notice any of these signs, it is important to have the poppet assembly inspected and serviced as soon as possible.