SPECIFICATIONS FOR WATER JET CUTTING MACHINE PUMP | |

Potência Nominal | 40HP (30 kW) |

Pressão máxima | 420Mpa /4200bar/60,000psi |

Pressão de trabalho | 360-380Mpa |

Diâmetro máximo do orifício | 0.33 milímetros |

Max.Flowrate | 3.8L/min |

Capacidade do acumulador | 1L |

Tamanho | 1600mm*1200mm*1100mm |

Peso | 0.9t |

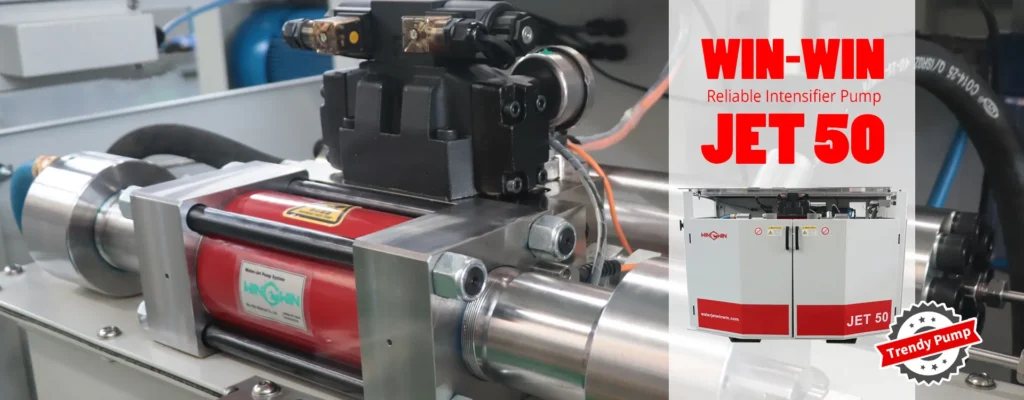

1: The core technology of the intensifier has been used in the market for more than 30 years. It is a intensifier with high cost performance and strong stability. The core components are international universal, the supply is sufficient, and the price is cheap.

2: The control system PLC adopts the Omron brand, Omron brand PLC technology is stable, suitable for working in various environments, and the performance is reliable, which makes the waterjet cutting machine more stable.

3: New reversing valve,whick has quick response and low noise, reducing reversing pressure attenuation, making the pressure more stable.

4: 1L accumulator without rubber seal overall , maintenance-free, will never damage.

5: 40HP/50HP motor.WINWIN mostly uses 40HP motors, because after many tests 40HP motors are enough to reach the rated pressure, and can save electricity costs for customers at the same time .The standard equipment is 40HP motors unless special needs for using 50 HP.

6: The low-pressure water pump adopts stainless steel impeller and copper core structure to prevent the internal rust of the water and cause orifice congestion and other failures.

7: The heat exchanger uses a folding structure, which takes up little space, has a large internal heat dissipation area, and has a very good heat dissipation effect.

8: The independent variable oil pump completes the process of starting at low pressure, waiting at zero pressure, and running at high pressure, reducing the load on the motor, reducing the heat dissipation of the system, and allowing the equipment to save electricity costs at the same time.

Stable and durable features make WW50jet intensifier pump very popular. Many customers choose this intensifier pump, equipped with 5-axis cantilever platform, cutting tiles, marble, metal and other materials.WW50JET adopts excellent booster technology, equipped with double water filter element, oil filter, various alarm systems, the performance has been verified, it is a qualified waterjet cutting machine in the minds of customers.WW50JET provides customers with more commercial value, fully open design, good heat dissipation performance.The design of the oil tank is placed under the intensifier, which makes the intensifier more stable during work.In a word, this machine is an great option you can consider.

WW50JET equipment is currently produced in a production line. The frame is welded by an automated robot, which can ensure that the frame is strong and durable. After sandblasting, rust removal, anti-rust paint and baking paint,.etc processes to complete the production. And the are installed. The material of screws for installing the frame of the waterjet intensifier pump is stainless steel and requires grade 12.9. The beauty of the frame represents the strength of the factory.

The intensifier of WW50JET is international universal , and each part is standard. Before installation, it is necessary to deal with surface impurities and check whether there are scratches on the parts. Waterjet spare parts are all important, and the surface of many parts is sealed.So waterjet parts cannot touch the ground, each part should be placed in a special package, installed on the intensifier by engineers, waiting for testing.

We ensure that each set of equipment is qualified, strictly inspected in the factory and continuously started for 24 hours, observe the parameters such as sound, oil temperature, operating status of individual components, pressure fluctuations, etc., and make records. This is what manufacturers should do as a waterjet cutting equipments production .