Sistema de Corte a Jato de Água Robô ABB

The above ABB robot waterjet cutting system for automotive interior carpet cutting, the above video shows the process of the whole set of equipment from scratch, the arrival of the robot, the construction of the frame, the establishment of the cutting table, the completion of the whole set of equipment, and the demonstration work.

- Do you need a robot waterjet cutting workstation with high work efficiency, high safety and high precision, then this set will be a good choice.

The details of this ABB robot waterjet cutting system:

1, Two ABB IRB 2600 ceiling type robot arms

2, Fully enclosed house design

3. Turn table/rotary table for your choice

4. Drip tray to collecting the dripping water

5. Omron safety fence

6. Siemens control panel

7. SL-VI 50 HP dual waterjet intensifier pump

8. Industrial chiller

9. Vacuum adsorption system

Designing the Robot Waterjet Cutting Workstation as a fully enclosed house style has the following benefits:

Safety and Security of the robot waterjet cutting: The fully enclosed housing design provides a higher level of safety and security. Since the waterjet cutting process generates splashing water and cutting waste, the fully enclosed housing design effectively prevents these substances from harming the surrounding environment and operators. The enclosed structure of the workstation blocks the splashing of water and waste materials, reducing the risk of operator contact with materials from the cutting process.

Environmental Control of the robot waterjet cutting: The fully enclosed house style design provides better environmental control. During the cutting process, water jet cutting generates a certain amount of noise and water vapor. The enclosed housing design effectively isolates noise and water vapor, reducing noise levels around the workstation, improving the working environment and reducing the impact on ambient air quality.

Operator Protection of the robot waterjet cutting: The fully enclosed housing design provides improved operator protection. During the water jet cutting process, the operator needs to be at a safe distance from the robot and the cutting area to avoid injury from the water jet. A fully enclosed housing design allows the operator to observe the cutting process through transparent walls or windows, while ensuring their safety.

Material Control of the robot waterjet cutting: The fully enclosed housing design provides better material control. Waterjet cutting generates large amounts of waste and debris during the cutting process. A fully enclosed housing design collects and controls this waste material, preventing it from being dispersed into the surrounding environment and facilitating subsequent disposal and cleanup of the waste material.

Suitable for Specialized Environments of the robot waterjet cutting: Totally Enclosed Housing is suitable for locations that require specialized environmental controls. For example, in some special industrial environments, such as the presence of hazardous gases, dust or chemicals, the fully enclosed housing design can provide additional protection to ensure the safety and reliability of the cutting process.

In summary, designing a robotic waterjet cutting workstation as a fully enclosed house can provide increased safety and security, environmental control, operator protection, material control, and the advantage of being suitable for specialized environments. Such a design improves the working environment of the cutting workstation, reduces risks and hazards, and improves efficiency and quality of work.

3, Rotary cutting table with drip tray cutting box

Robot Waterjet Cutting Workstation matched with rotating cutting table and hanging robot, working efficiency is greatly improved.

The entire workflow of the rotary cutting table from start to finish takes only 7 seconds, which is very fast.

How does our rotary table guarantee operational accuracy?

We do it through three aspects: servo motors, sensors, and positioning pins.

4, Comprehensive safety and security system of the robot waterjet cutting system:

There are comprehensive safety tips in the simple operator console to provide safety for the operator and if one of the start indicators fails then the robot will not start. For example, if there are people or foreign objects in the safe operating area, if the safety door is not closed, if the robot is not returned to its position, if there are alarms or abnormalities, and so on.

The following video shows the overall working of our robot waterjet cutting system and a full view of the entire workstation.

Of course, our robot waterjet cutting system also guarantees high performance in other ways.

Matched with our SL-VI (50HP) high performance high pressure pump of the robot waterjet cutting system, it works stably, operates intelligently, has a low failure rate, and the parts are used for a long time.

For example, it is equipped with a high-power chiller for the robot watejet cutting system, which is specially designed for high-end waterjet cutting machines, with powerful refrigeration effect, no pressure for long time working, and no wearing parts.

Also matched with our high efficiency industrial water purification and filtration system for the robot watejet cutting system, so that robot waterjet cutting system in use completely without worrying about the water quality of the problem caused by the machine damage.

If you are interested in any robot waterjet cutting system, contact us please.

Or you can click this link into our YouTube to know more waterjet products.

Which is the best waterjet supplier in China?

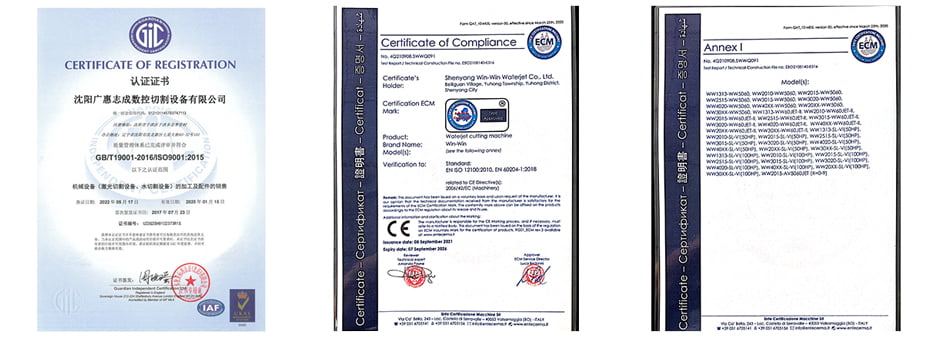

Win-Win Waterjet is a leading Chinese company in the waterjet cutting industry, known for its cutting-edge technology. The company serves a diverse range of customers, including suppliers to renowned automotive companies such as Mercedes-Benz, BMW, Volkswagen, and manufacturers of automotive interior and exterior components. Its primary products are robot waterjet cutting systems and related machine parts.

As a technology leader, Win-Win Waterjet focuses on innovation and research and development to provide high-quality waterjet cutting solutions. The robot waterjet cutting system is one of the core offerings, combining advanced robotics and high-pressure waterjet cutting technology to achieve precise and efficient cutting processes. This system finds extensive applications in the automotive industry, enabling accurate cutting of various automotive parts, including body panels, interior components, and exterior trims. By utilizing the robot waterjet cutting system, customers can enhance production efficiency, product quality, while reducing costs and energy consumption.

In addition to robot waterjet cutting systems, Win-Win Waterjet supplies a wide range of related machine parts to cater to diverse customer needs. These components include high-pressure waterjet cutting heads, cutting tools, control systems, and more, providing comprehensive support and technical services to customers.

With a dedicated team of R&D and technical support professionals, Win-Win Waterjet remains committed to driving innovation and improving product performance and technical details to meet customer requirements. The company also emphasizes collaboration and communication with customers, offering customized solutions and technical support based on specific needs.

Win-Win Waterjet aims to become a global leader in the waterjet cutting industry, earning the trust and support of customers through continuous innovation and exceptional products and services. Guided by the principle of “win-win cooperation,” the company strives to forge partnerships with customers and jointly create a better future.

Win-Win’s comprehensive product line:

As the leader of China’s waterjet industry, Win-Win has experienced more than 20 years of experience in the industry and enjoys a good reputation in the waterjet industry both at home and abroad. We have served users in more than 30 countries around the world, including glass cutting, metal cutting, stone cutting, aerospace and automotive interior and exterior industries, etc. We have established a good cooperative relationship with our customers, and truly achieved mutual benefit and common growth.

Up to now, our products cover almost all categories of waterjet cutting products, such as robot waterjet cutting system, abrasive waterjet cutting machine (3 axis waterjet cutter & AC 5 axis waterjet cutter), portable waterjet cutting machine, waterjet pump (60k psi, 90k psi and the direct drive pump etc.), waterjet spare parts for major brands and also Chinese brand etc.

Other devices, such as auto abrasive removal system for the waterjet cutting table to clean the abrasives and cutting crips in the water sink.

There are also products from related industries: such as accessories for laser cutting machines, ABB robot, FanUc robot, Kuka robot parts etc.

Win-Win is based on technology and is an innovative enterprise:

Our leader is a former technical professional from a renowned brand in the waterjet industry. Over the years, they have been dedicated to researching waterjet cutting products and technologies, aiming to provide customized service solutions to our customers.

With a wealth of experience and expertise in the field of waterjet cutting, our leader brings a deep understanding of the industry and a commitment to excellence. They have consistently stayed at the forefront of technological advancements, ensuring that our company remains at the cutting edge of innovation.

At our company, we pride ourselves on delivering tailored services to meet the unique needs of our clients. Our leader’s expertise allows us to develop customized service projects that align with the specific requirements and expectations of our customers. Whether it’s designing intricate patterns, achieving precise cuts, or optimizing production efficiency, we strive to provide the highest quality solutions.

Our leader’s extensive knowledge and industry insights enable us to offer comprehensive support and guidance throughout the entire waterjet cutting process. From initial project consultation to final execution, we are dedicated to ensuring customer satisfaction and exceeding expectations.

By leveraging our leader’s technical prowess and their continuous pursuit of excellence, we are committed to delivering exceptional results to our valued clients. We understand the importance of staying ahead in a rapidly evolving industry, and we are confident that our team’s expertise and dedication will continue to drive our success.

The following pictures show some of our robot waterjet cutting equipment cases and pumps.