Descrição

Waterjet spare parts 20478196 Pump/manifold assembly

Technical answers about Waterjet spare parts 20478196 Pump/manifold assembly:

What are the reasons for the insufficient pressure of the waterjet intensifier pump?

Five reasons for the insufficient pressure of the waterjet intensifier pump:

There are many reasons for no oil pressure:

1: First of all, it may be caused by the wear or failure of related wearing Waterjet spare parts. Judgment method: close the outlet valve of the Waterjet spare parts water jet cutting head – turn on the high pressure – look at the current pressure of the oil gauge, if the current pressure of the oil gauge is less than 320Mpa, and within 5 minutes the intensifier pump does not change direction, which proves that it is not a failure of high-pressure water wearing Waterjet spare parts.

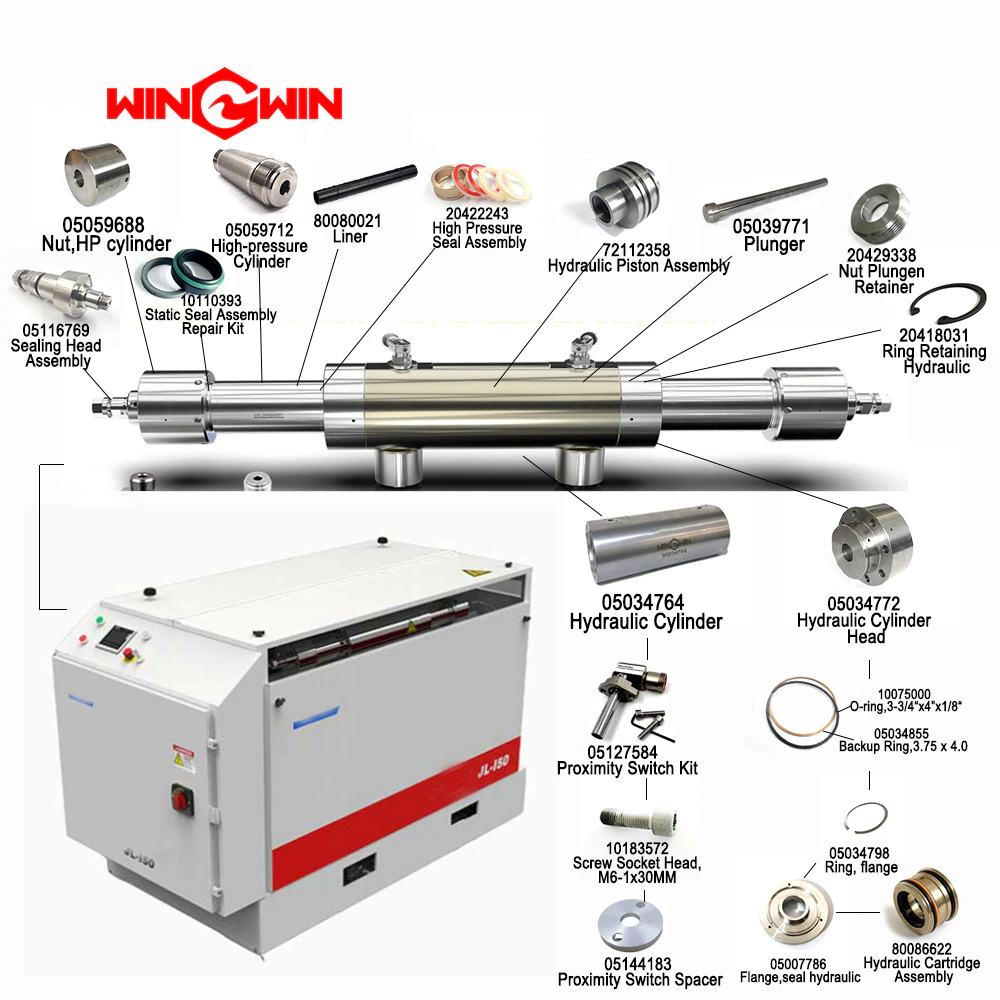

Which consumables with high pressure discharge check valve?

2(poppet pin), 3(compression spring), 4(discharge poppet check valve), and 5(seat) in the figure below are all vulnerable Waterjet spare parts, and the service life of 5 seat is about 20 days (depending on the water quality). When the machine has insufficient pressure, if it is judged that it is the wear of the Waterjet spare parts High pressure discharge check valve As a result, first replace the 5 seat, if this has no effect, then you need to check whether the plane of other corresponding parts is worn, such as whether the contact surface of Waterjet spare parts check valve body/sealing head body is worn or scratched, if these conditions exist , the surface can be polished or directly replaced with a new one.

2: It may be that the independent variable pump is worn. Judgment method: There is a thin tube on the independent variable pump, which is a thin oil tube that connected to the fuel tank. In normal operation, the oil return volume of this oil tube is small. If in normal operation, the oil return volume of this oil pipe is very sufficient, even reaching the state of spraying, which proves that the independent variable pump is worn and needs to be replaced.

3: The pressure regulating valve is damaged: Rotate the pressure regulating valve, the pressure does not change, or the pressure is unstable, please remove the pressure regulating valve to clean, and then install and test, if the fault has not been improved at this time, please replace the pressure regulating valve.

4: Relief valve damage: There is an overflow valve on the oil path plate of the waterjet intensifier pump. When the overflow valve is damaged, the pressure of the water jet cutting pump is very low, which is because the overflow valve is damaged and too much hydraulic oil passes through the overflow valve, resulting in the reduction of oil pressure. In this case, the overflow valve should be replaced. You can judge by listening to the noise or watching the normality of the intensifier pump oil return.

5: Piston seal wear: Judgment method: close the water outlet valve of the cutting head, turn on the high pressure, wait for five minutes, and observe whether the intensifier pump reverses direction. If the intensifier pump can reverse direction, it means that the piston seal is worn, or the wearing parts of the check valve assembly are worn, please replace it corresponding parts.

Piston seals (See the below picture item 1 piston seal assembly)

If your water jet intensifier pump has no pressure, you can troubleshoot according to the above tips. We can also provide you with online technical consultation or guide you to solve the problem through video calls. About 20478196 Pump/manifold assembly we have stock, if you need to order, please contact us.