Descrição

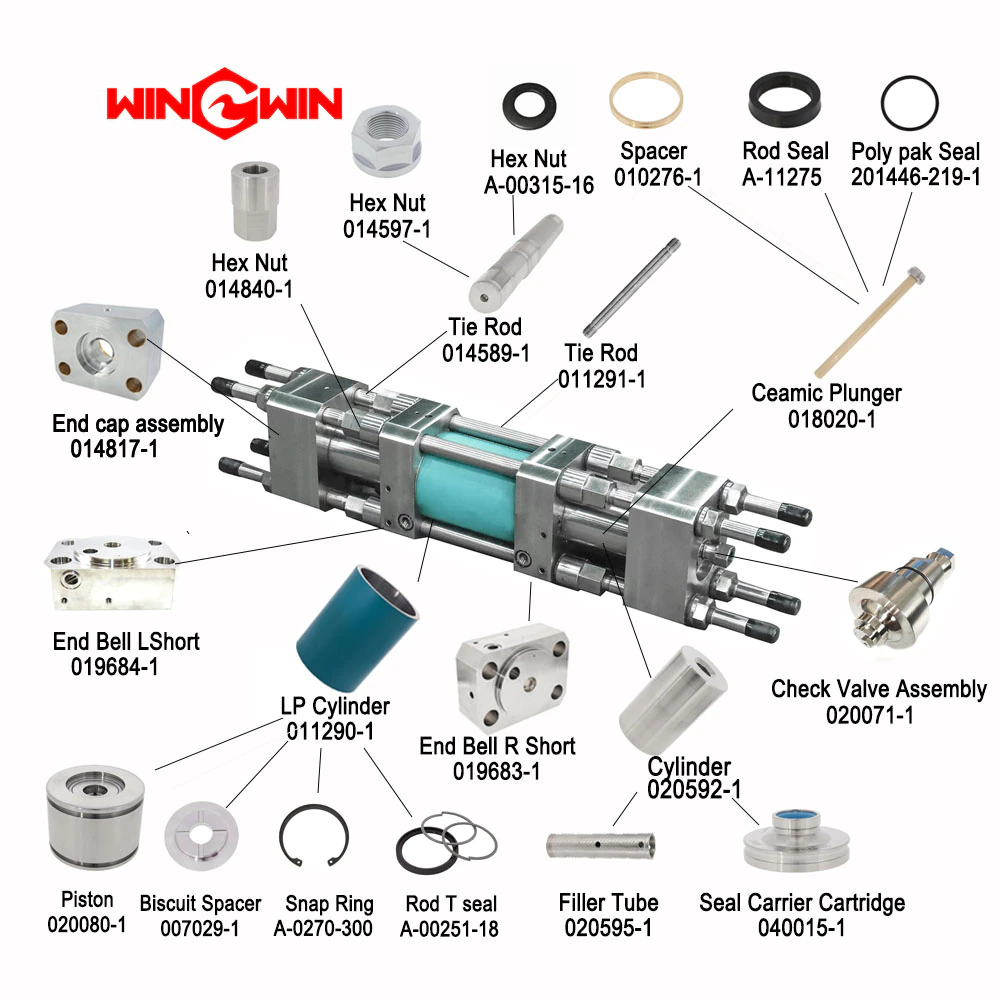

The waterjet cutting piston is equipped with a seal and an anti-wear belt, which is best installed by the waterjet cutting manufacturer because it is easily damaged by the customer’s own installation.

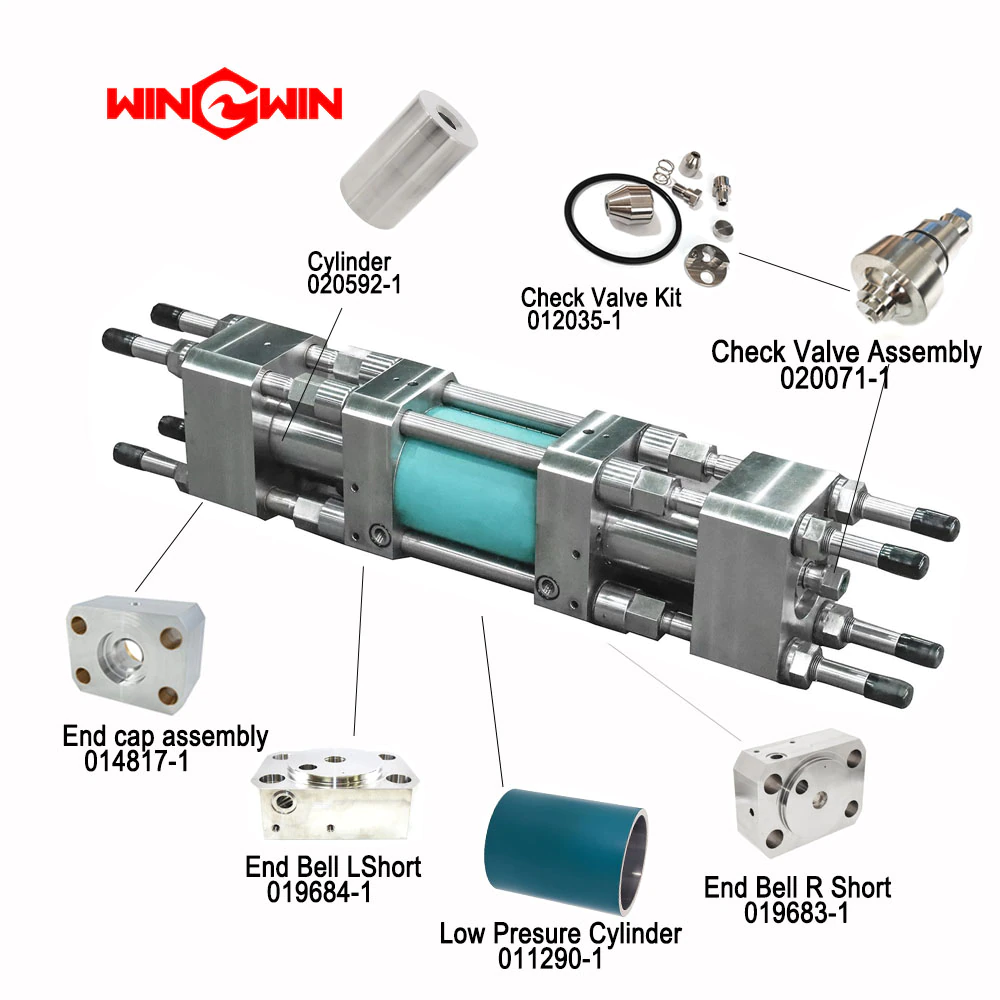

Speaking of the waterjet pump parts, here we will explain what parts need to be replaced for waterjet cutting machine.

First, the waterjet nozzles and mixing tubes are the easiest to be replaced. The use time of waterjet nozzle is generally about 80h, and the use time of waterjet mixing tube is about 120h. These two Parts are standard waterjet Pump Parts. We recommend that customer to buy ten or twenty of these two parts together, because of the high use frequency, and if order large quantity can also get more favorable prices.

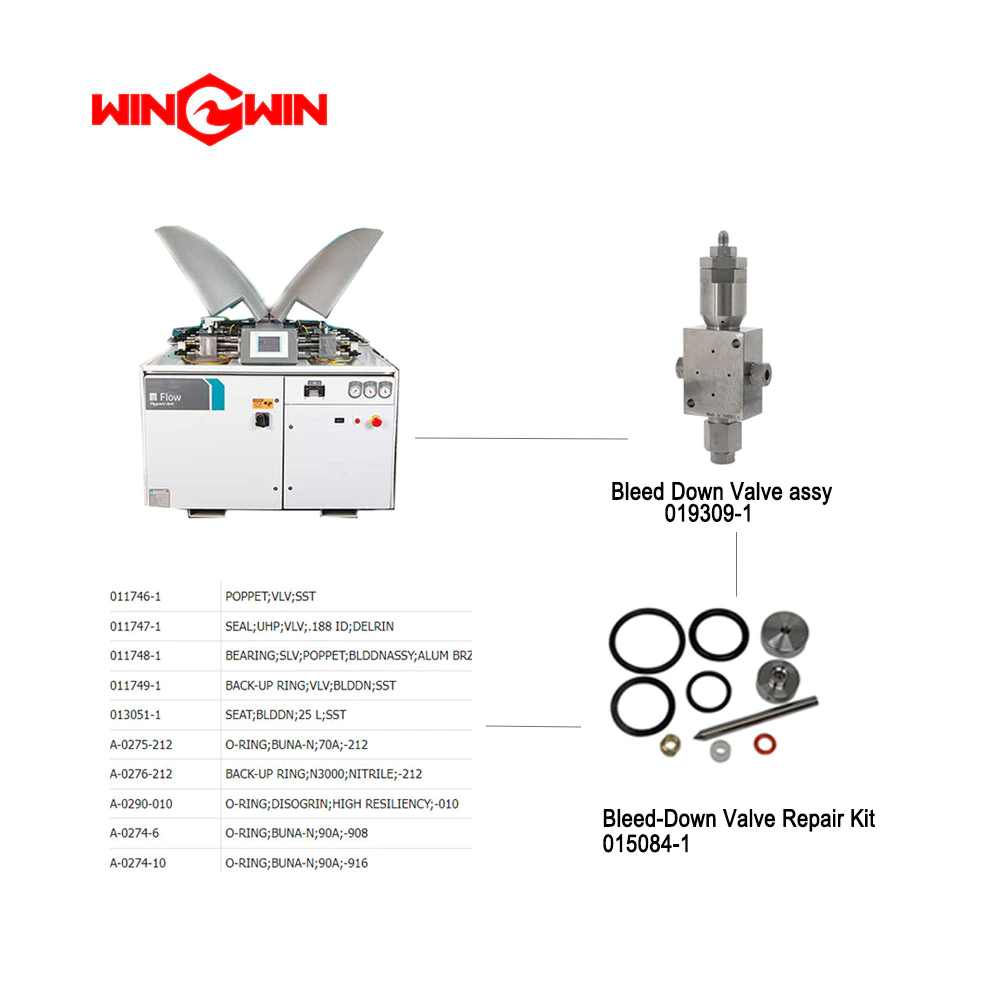

The second reason is that the waterjet parts that used on the intensifier pump is very standard, outlet poppet, insert, poppet, check valve main body, seal plunger, and so on. If you need the whole set of parts, please contact us for a complete list. We need to mention some Parts that are not commonly used here, but the customer needs to prepare for the waterjet Pump Parts. In many cases, the customer neglect one of waterjet Pump Parts, that is, the Water filter. Customers need to replace this part often, many customers will not notice, do not often change the Water filter, that will cause the nozzles are easy to block, which will cause waste, many customers do not know this reason.

Do you know why are waterjet Pump Parts hydraulic Piston damaged?

1. Check the quality of hydraulic oil. Many times the damage to waterjet Pump Parts hydraulic Piston is because the quality of hydraulic oil is not good, or the use of hydraulic oil for too long and the viscosity is reduced. Normal hydraulic oil should have a certain viscosity, and the color is light yellow, when the hydraulic oil of the waterjet cutting machine becomes white, or the viscosity is low, then it’s the time for the hydraulic oil needs to be replaced, and this will avoid the damage to the hydraulic parts

2: Whether to place a strong magnet inside the oil tank, because the equipment in the operation process, the independent variable pump or the waterjet intensifier will wear, so a lot of iron powder will enter the oil tank, if there is no strong magnet inside the tank, these iron powders will cause the wear of hydraulic components, Or cause waterjet Pump Parts hydraulic Piston seal failure, the result is insufficient pressure for cutting work