Descrição

Introduction

Waterjet cutting is a precise and versatile method of cutting various materials, and it is commonly used in many industries, including aerospace, automotive, and manufacturing.

The key to the accurate and effective operation of a waterjet cutting system is the high pressure jet pump that generates the water stream.

One of the critical components of a waterjet pump machine is the attenuator assembly, which helps regulate the flow and pressure of the water.

The following parts will introduce the 20478834 Attenuator Assembly, 1.6L, which is commonly used in the 90k waterjet pump machine.

We will also discuss the water jet pump working principle, the different types of pumps used in waterjet cutting, the efficiency of waterjet pumps, and the pressure required for effective waterjet cutting.

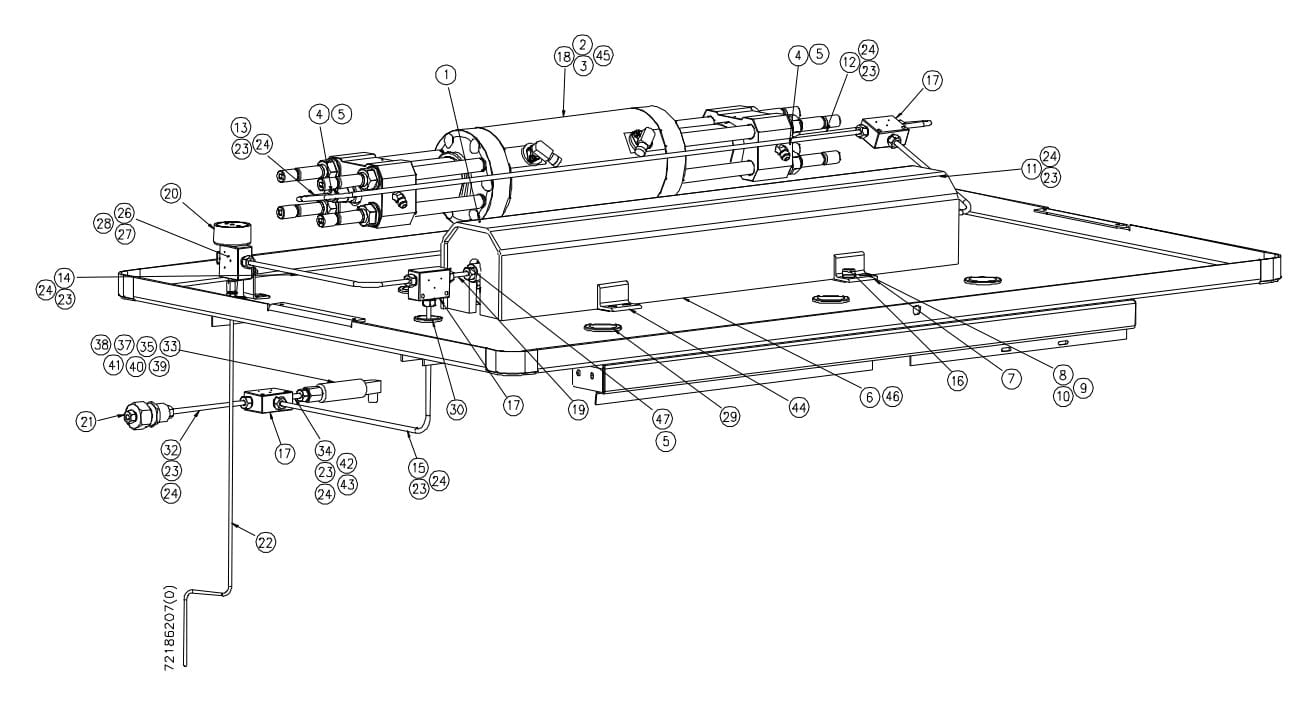

Item | Part Number | Descrição | Quantity | Item | Part Number | Descrição | Quantity |

1 | 20478834 | Attenuator Assembly, 1.6L | 1 | 23 | 10083897 | Ferrule, Hose, .25 | 10 |

2 | 95383790 | Socket Head Screw, 1/2-13 x 1 | 4 | 24 | 10186153 | Flexible Conduit, .38 | 150.0″ |

3 | 95413696 | Lock Washer, .50 | 4 | 26 | 72158122 | Socket Head Screw, 1/4-28 x 5/8 | 2 |

4 | 20452956 | UHP Gland, .38 | 2 | 27 | 95838314 | Lock Washer, .25 | 2 |

5 | 20452965 | UHP Collar, .38 | 4 | 28 | 95391322 | Flat Washer, .25 | 2 |

6 | 20480175 | Attenuator Housing | 1 | 29 | 49831480 | Grommet, 3.0 | 7 |

7 | 05144837 | Spacer, Attenuator Bracket | 4 | 30 | 20419432 | Grommet, 2.25 | 2 |

8 | 95660957 | Flat Washer, .38 | 8 | 32 | 72160706 | UHP Tube, .38 x 11.10 | 1 |

9 | 95670972 | Lock Washer, .38 | 8 | 33 | 72160914 | Pressure Transducer | 1 |

10 | 95375473 | Socket Head Screw, 3/8-16 x 1 | 8 | 34 | 20468830 | UHP Tube, .38 x 4.81 | 1 |

11 | 72158312 | UHP Tube, Bent, .38 | 1 | 35 | 10067205 | Cable Connector, .50 | 1 |

12 | 72131795 | UHP Tube, Bent, .38 | 1 | 37 | 72120528 | Resistor | 1 |

13 | 72131788 | UHP Tube, Bent, .38 | 1 | 38 | 72158140 | Kit, Screen Ground | 1 |

14 | 72158403 | UHP Tube, Bent, .38 | 1 | 39 | 10083012 | Lock Nut, .50 | 1 |

15 | 72158411 | UHP Tube, Bent, .38 | 1 | 40 | 10082857 | Gasket Assembly, .50 | 1 |

16 | 20491892 | Cup Seal | 1 | 41 | 05143631 | Cable, #18 | 130.0″ |

17 | 20455812 | Tee Assembly, UHP, .38 | 3 | 42 | 10078715 | HP Collar, .38 | 1 |

18 | 72170165 | Intensifier Topworks | 1 | 43 | 10078129 | HP Gland, .38 | 1 |

19 | 20478653 | UHP Tube, .38 x 5.0 | 1 | 44 | 72170474 | Foam Strip | 16.0″ |

20 | 20468634 | Pneumatic Valve/Actuator Assembly | 1 | 45 | 49898729 | Flat Washer, M12 | 4 |

21 | 20464737 | Coupling, Bulkhead, UHP, .38 x .38 | 1 | 46 | 10112662 | Neoprene | 48.0″ |

22 | 72175565 | UHP Tube, Bent, .25 | 1 | 47 | 72169600 | Gland Assembly, .38 | 2 |

Water Jet Pump Working Principle

The principle behind a jet pump involves the injection of pressurized power fluid, such as water or oil, into the power fluid flow path at a predetermined rate and pressure.

As the fluid enters the high pressure jet pump, the flow path area is reduced by a sized nozzle, causing the fluid’s velocity to increase and creating a venturi effect.

This principle is essential in waterjet machining as it enables the high-pressure water to cut through challenging materials with ease.

This principle is critical in waterjet machining, as it allows for the high-pressure water to cut through tough materials.

The waterjet cutting process is a complex one that involves a few key components.

The high pressure jet pump is responsible for generating the water stream, which is then directed through a nozzle to create a high-velocity stream that can cut through various materials.

The pump’s working principle involves the use of a hydraulic piston or a rotating impeller to compress water and produce high pressure, depending on the type of pump used.

Types of Pumps Used in Water Jet Machining

There are two types of pumps used in waterjet cutting: the linear intensifier pump and the rotary direct drive pump.

Both pumps are capable of reliably delivering ultra-high-pressure water, and both are successfully used in industry.

The linear intensifier pump uses a hydraulic piston to compress water and produce high pressure.

In contrast, the rotary direct drive pump uses a rotating impeller to produce high pressure.

The choice of pump used in a waterjet cutting system depends on several factors, including the desired pressure and flow rate, the size of the system, and the type of materials being cut.

Efficiency of a Water Jet Pump

The theoretical maximum ideal pumping efficiency of a waterjet pump machine is 50% at a flow ratio of unity.

However, in reality, various factors can affect the efficiency of a waterjet pump machine, including the design of the pump, the operating conditions, and the maintenance of the pump.

Some of the key factors that affect the efficiency of a waterjet pump machine include the pressure, flow rate, nozzle size, and the type of abrasive used.

To ensure the efficient operation of a waterjet pump machine, it is essential to perform regular maintenance, includingchecking the seals and gaskets, replacing worn out parts, and cleaning the system to prevent clogs or blockages.

Correct maintenance can help ensure that the pump operates at maximum efficiency, resulting in cost savings and improved performance.

Pressure of Water Jet Cutting Machine in PSI

In waterjet cutting, a high-velocity stream of ultra-high-pressure water ranging from 30,000-90,000 PSI (210-620 MPa) is used to cut materials.

This high-pressure water is generated by a high pressure jet pump that may or may not have abrasive particles suspended in the stream.

The high pressure is critical in ensuring that the water can cut through tough materials such as metals, ceramics, and composites.

The pressure required for effective waterjet cutting depends on various factors such as the material being cut, the thickness of the material, and the nozzle size, among others.

Careful calibration of the pressure is necessary to ensure optimal cutting performance.

The high pressure is critical in ensuring that the water can cut through tough materials such as metals, ceramics, and composites.

The pressure required for effective waterjet cutting rests with the material being cut, the thickness of the material, and the nozzle size.

The pressure should be carefully calibrated to ensure optimal cutting performance.

Comparison between Waterjet and Laser Cutting

Waterjet cutting is often compared to laser cutting as both methods are used for precision cutting of different materials.

While laser cutting is generally faster and more precise than waterjet cutting, waterjet cutting is more versatile and can cut a wider range of materials, including materials that are not fit for laser cutting.

In terms of cost, laser cutting costs about $13-$20 per hour, while waterjet cutting has a general range of $15-$30 per hour.

The cost of waterjet cutting depends on factors such as the type of material being cut, the complexity of the design, and the thickness ofthe material.

20478834 Attenuator Assembly, 1.6L in 90000 PSI Waterjet Pump Machine

The 20478834 Attenuator Assembly, 1.6L is a critical component in 90000 PSI waterjet pump machines.

This assembly helps adjust the flow and pressure of the water, ensuring that the pump operates efficiently and effectively.

The attenuator assembly is designed to minimize pressure fluctuations in the water jet system, which can affect the cutting precision and cause premature wear and tear on the pump’s components.

The 20478834 Attenuator Assembly, 1.6L features a compact design and is easy to install and maintain.

The assembly is designed with high-quality materials to withstand the harsh operating conditions of water jet cutting.

The assembly consists of a diaphragm, a piston, and a spring, which work together to regulate the pressure of the water in the system.

The diaphragm separates the air and water in the system, preventing the air from being compressed and causing pressure fluctuations.

The piston is responsible for regulating the pressure of the water, while the spring helps maintain a constant pressure in the system.

The assembly is also designed to be durable and long-lasting, reducing the requirement for frequent replacements and repairs.

Conclusão

Waterjet cutting is a precise and versatile method of cutting various materials, and the high pressure jet pump is a critical component of the system.

The attenuator assembly, such as the 20478834 Attenuator Assembly, 1.6L, plays a vital role in regulating the flow and pressure of the water, ensuring efficient and effective operation of the pump.

Understanding the water jet pump working principle, the different types of pumps used, the efficiency of waterjet pump machines, and the pressure required for effective waterjet cutting is essential for choosing the right pump and components for your cutting needs.

By choosing high-quality components, such as the 20478834 Attenuator Assembly, 1.6L, users can ensure that their water jet pumps operate efficiently and effectively, providing reliable and consistent performance for their cutting needs.

Regular maintenance of the system is also crucial to ensure that the pump operates at maximum efficiency, resulting in cost savings and improved performance.

In conclusion, the 20478834 Attenuator Assembly, 1.6L, is a critical component of 90000 PSI waterjet pump machines, helping regulate the flow and pressure of the water to ensure efficient and effective operation.

By understanding the principles of waterjet cutting and choosing the right components, users can optimize their cutting performance and achieve their desired results.

Any other requirements for waterjet pump machinesPor favor consult with us.