Descrição

Waterjet parts: Adhesive thread locker

Item number: 49877509

DetalheS: Usado na máquina de corte a jato de água SL-VI 100HP

Relacionado peças de jato de água:

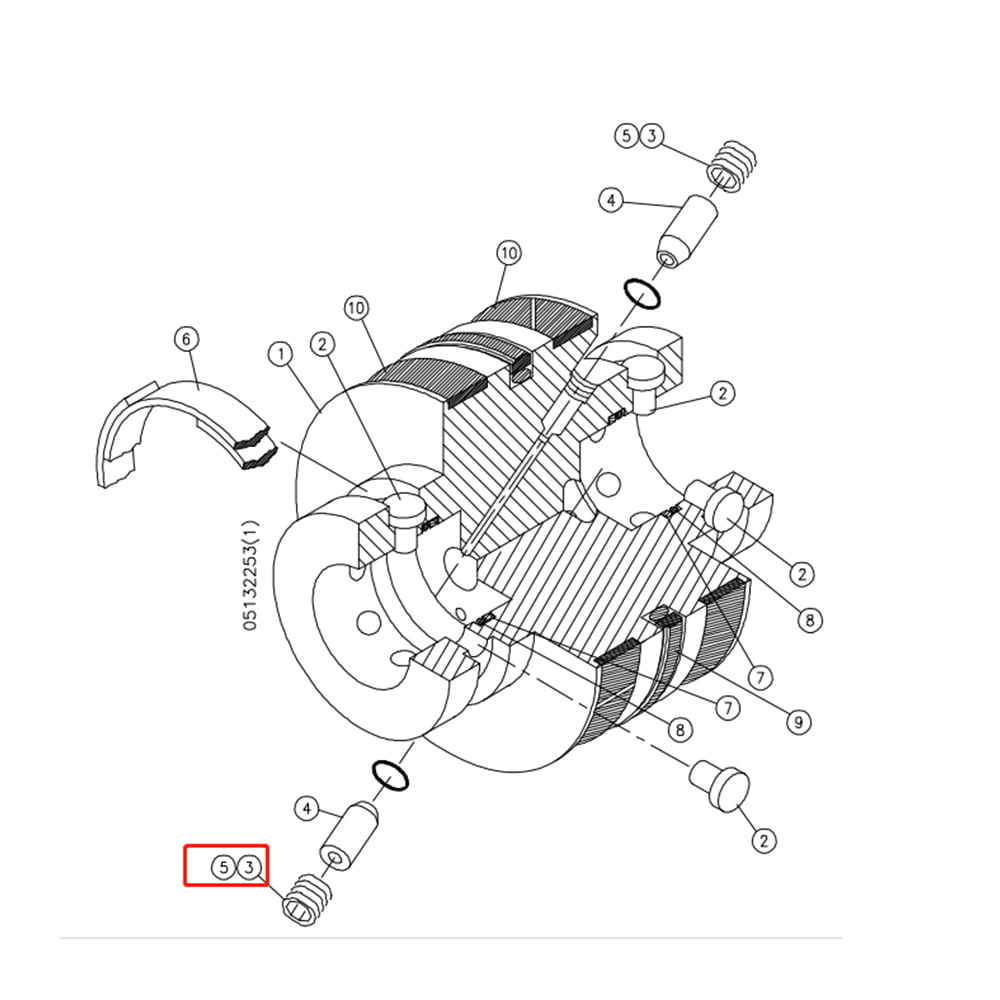

| Número do item | Descrição |

| 10192961 | Waterjet parts Socket head screw M12 x 1.75 x 30 mm |

| 10069763 | Waterjet parts Flat washer .50 |

| 72112043 | Waterjet parts Manifold assembly |

| 10151470 | Waterjet parts Adapter ORB/JIC 1.0 x .75 |

| 05091301 | Waterjet parts Gear pump hydraulic |

FAQ of platform waterjet machine & waterjet spare parts etc.:

Advantages of Waterjet Cutting:

Versatility: Waterjet cutting can be used on a wide range of materials, including metals, stone, glass, composites, plastics, and more. It is suitable for both conductive and non-conductive materials, making it a versatile cutting method.

Precision: Waterjet cutting offers high precision and accuracy, allowing for intricate detailing, sharp corners, and tight tolerances in the cut. It can achieve complex shapes with excellent edge quality.

No Heat-Affected Zone (HAZ): Waterjet cutting is a cold cutting process, meaning it does not generate heat during the cutting process. This eliminates the risk of heat distortion, hardening, or changes in the material properties that can occur with heat-based cutting methods.

Clean and Burr-Free Cuts: Waterjet cutting produces clean, smooth edges without burrs, reducing the need for additional finishing operations. It creates a high-quality cut surface without altering the material’s inherent properties.

Minimal Material Waste: Waterjet cutting produces a narrow kerf width, resulting in minimal material wastage. The close nesting of parts during cutting maximizes material utilization and reduces overall material costs.

Environmentally Friendly: Waterjet cutting is considered an environmentally friendly cutting method. It does not produce hazardous fumes, gases, or dust.

Disadvantages of Waterjet Cutting:

Slower Cutting Speed: Compared to some other cutting methods like plasma or laser cutting, waterjet cutting is generally slower, especially for thicker materials. The cutting speed can be a limiting factor in high-volume production scenarios.

Higher Initial Investment: The equipment and machinery required for waterjet cutting can have a higher initial cost compared to some other cutting methods. The complexity and precision of the system contribute to the cost.

Limited Thickness for Certain Materials: While waterjet cutting can handle a wide range of thicknesses, there may be limitations in cutting very thick materials. In some cases, alternative cutting methods like plasma cutting or milling may be more suitable for extremely thick materials.

Noise and Water Disposal: Waterjet cutting can be noisy due to the high-pressure water stream and the abrasive particles.

Additionally, the disposal of used water and abrasive waste can require proper handling and wastewater treatment.A

brasive Wear: When cutting harder materials or using abrasive waterjet cutting, the abrasive particles can cause wear on the cutting nozzle and other components of the equipment.

Regular maintenance and replacement of consumables may be necessary. It’s important to consider these advantages and disadvantages when choosing the cutting method for a specific application. Waterjet cutting is particularly beneficial for its versatility, precision, and cold cutting nature, but factors like cutting speed and initial investment should also be taken into account.