Descrição

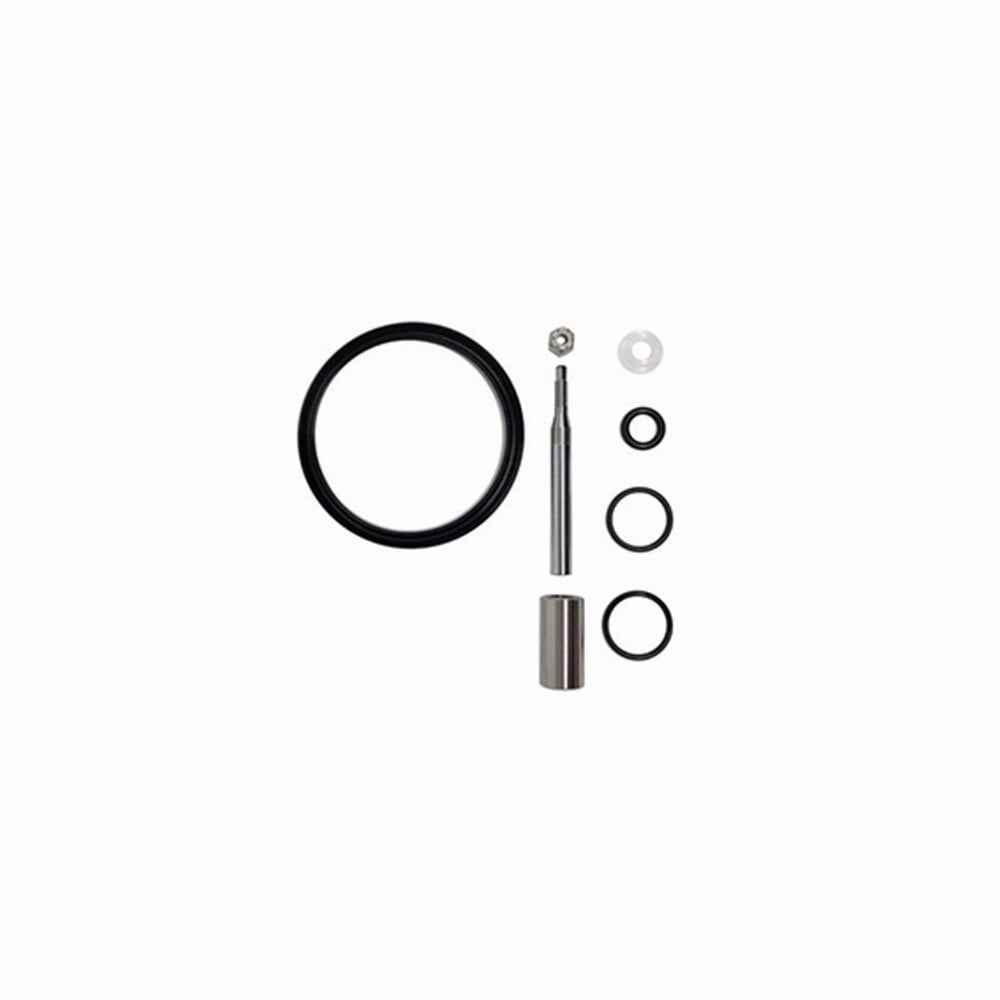

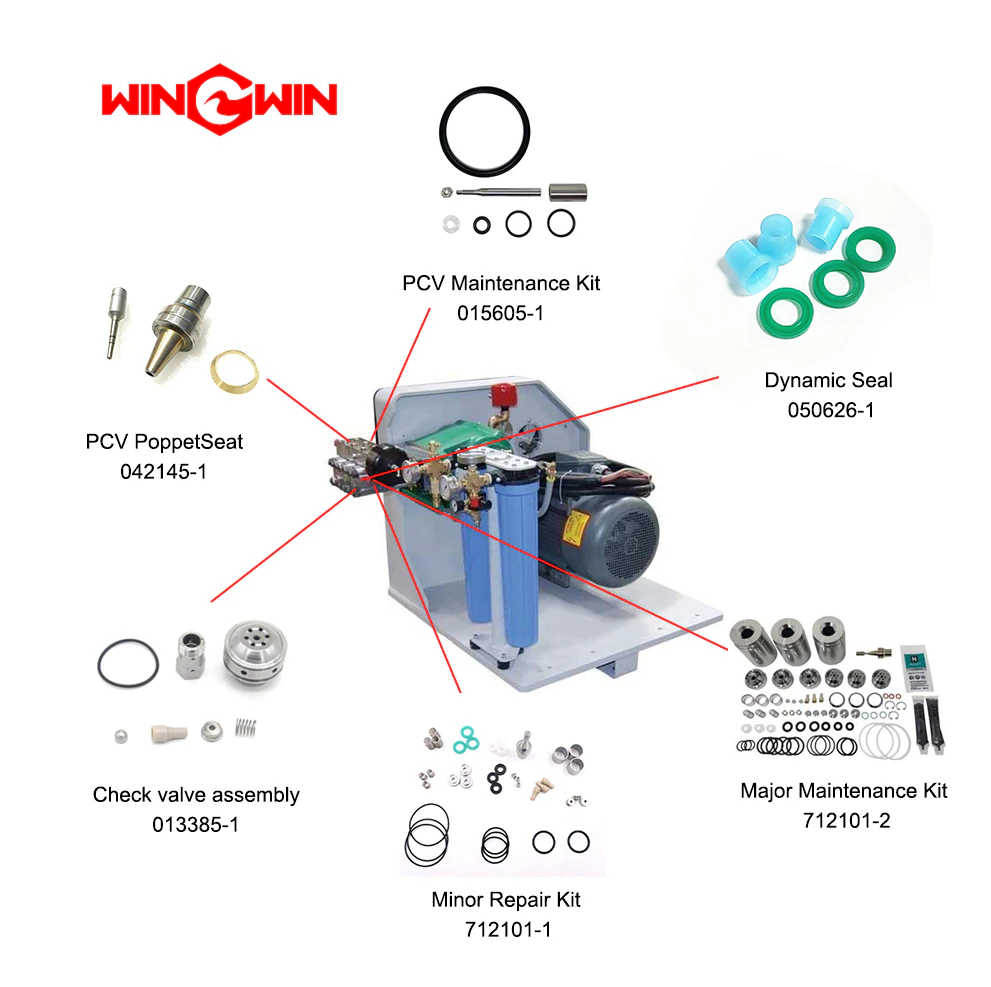

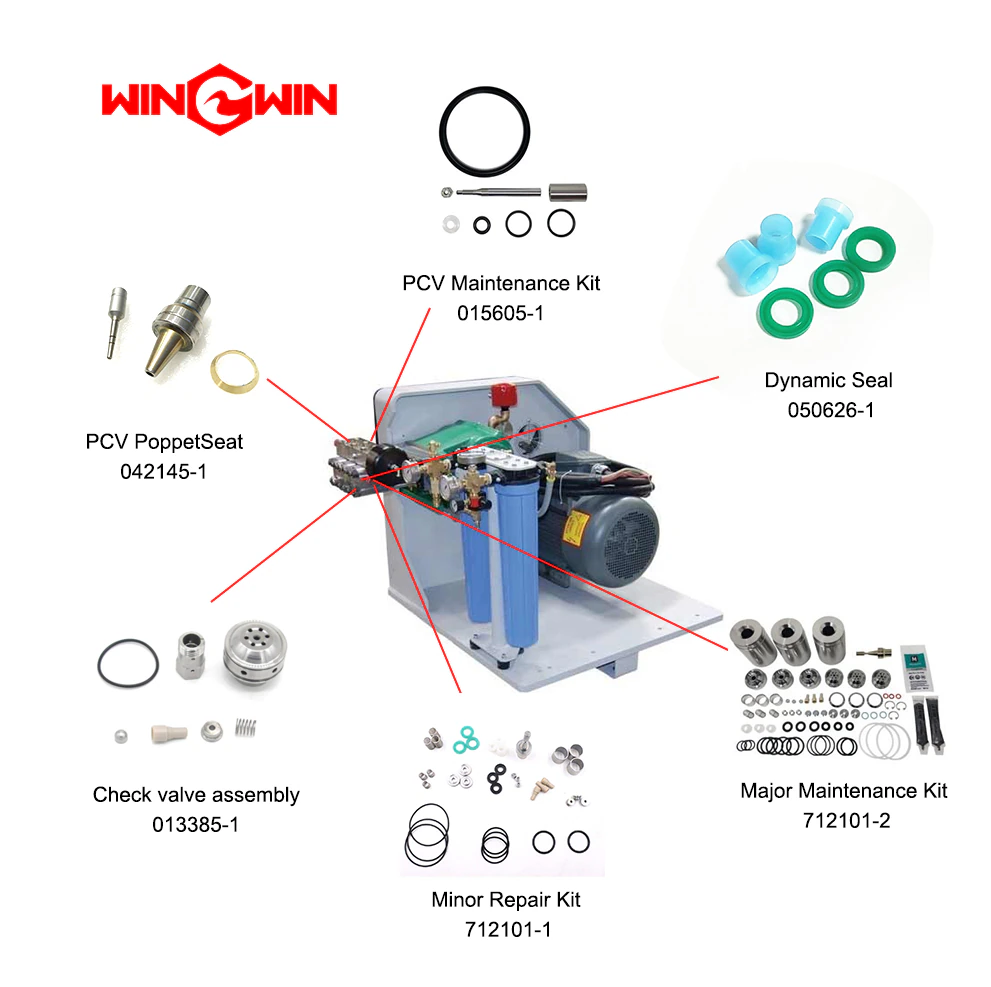

Waterjet Direct Drive Pump Parts PVC Maintenance Kit 015605-1 Hyplex Prime Waterjet Direct Drive Pump Water Jet Cutting Machine Parts

Questions and answers about waterjet cutting machines and Waterjet spare parts from waterjet cutting users.

- The cutting table size should be min 2000×4000 mm .

That’s ok, we have these sizes of cutting table: 2000x4000mm, 2500x4500mm, etc.

We can customize various sizes you need.

- I want to use it for granite and marble and ceramic material. Thickness to 40mm .

It’s ok, our AC-5AIXS waterjet cutting machine is especially suitable for cutting the materials and thickness you mentioned. The AC-5AXIS machine is the most suitable for cutting these materials and is chosen by manufacturers of kitchen and bathroom cabinets.

- The cutting head should be 5Axis up to 70°

It’s ok, AC-5axis can up to 70°, The cutting angle it can achieve is 0-70 degrees. Usually, glass is cut, metals are cut at 0 degrees, tiles are cut at 10 degrees, and marble and granite are cut at 45 degrees. So buying an AC-5axis machine can meet the needs of different cutting materials and cutting effects.

- I would like to know about the Program if it easy to use or not (and which language the program has ).

Yes, it is easy to use, and we can provide you with operating instructions and instructional videos.

Regarding the language, it can be used in multiple languages: Chinese, English and so on.

- About your service and the online support.

We can provide local service or online service.

- About the Parts that need to be changed frequently , and if I should to sell it at the same time with the machine .

If you buy our machine, I will give you some consumables and also provide you with a list of consumables.

- And the must important things is the Price.

Regarding the price of the machine, we have a very advantageous price in the same product configuration and quality.

- What equipment is included in the water jet cutting machine, and how to choose Waterjet pump, choose intensifier pump or waterjet direct drive pump? What is the difference between Intensifier pump and waterjet direct drive pump? What is the difference between the working principle of Intensifier pump and waterjet direct drive pump? What is the maximum working pressure that the Intensifier pump and waterjet direct drive pump can achieve?

Contains: waterjet cutting table, cutting head, high pressure pump, chiller, water softening system (optional item), abrasive removal system (optional item).

Regarding the high-pressure pump, it depends on what material the user needs to cut, what is the maximum thickness of the material, what is the customer’s budget, and what cutting efficiency do you want to achieve? Win-Win produces high pressure intensifier pump and waterjet direct drive pump. The maximum cutting working pressure is 55kpsi, 60kpsi and 90kpsi.

Intensifier pump is a hydraulic pump. Its working principle is to drive the pump to carry out uninterrupted piston movement through hydraulic pressure. The piston loosens and tightens. When it is loose, it will naturally store water, automatically fill tap water, and then squeeze the piston rod hydraulically. Let the natural water inside be squeezed to form ultra-high pressure, and finally form ultra-high-pressure water through the characteristics that the check valve cannot return, and then the high-pressure water jet flows to the cutting head, and finally the material is cut, depending on the material to be cut. The high pressure used can also be set to different values.

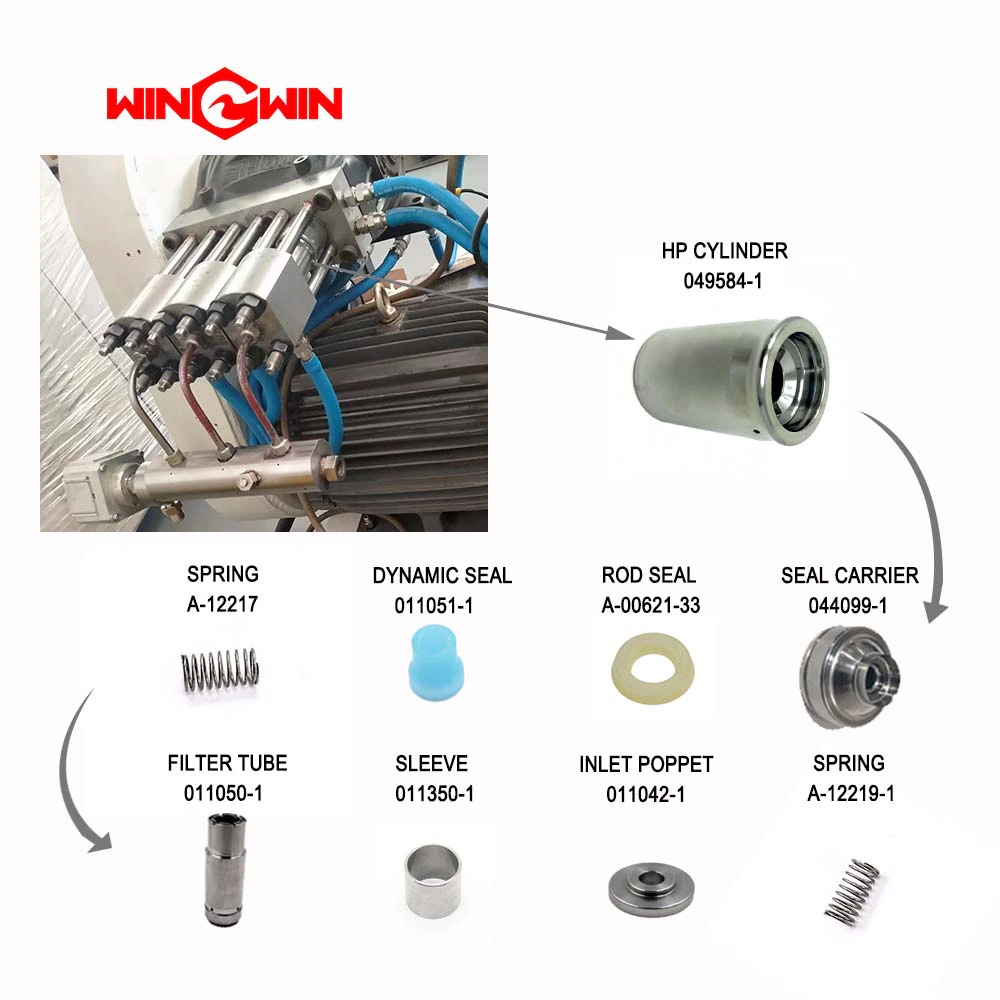

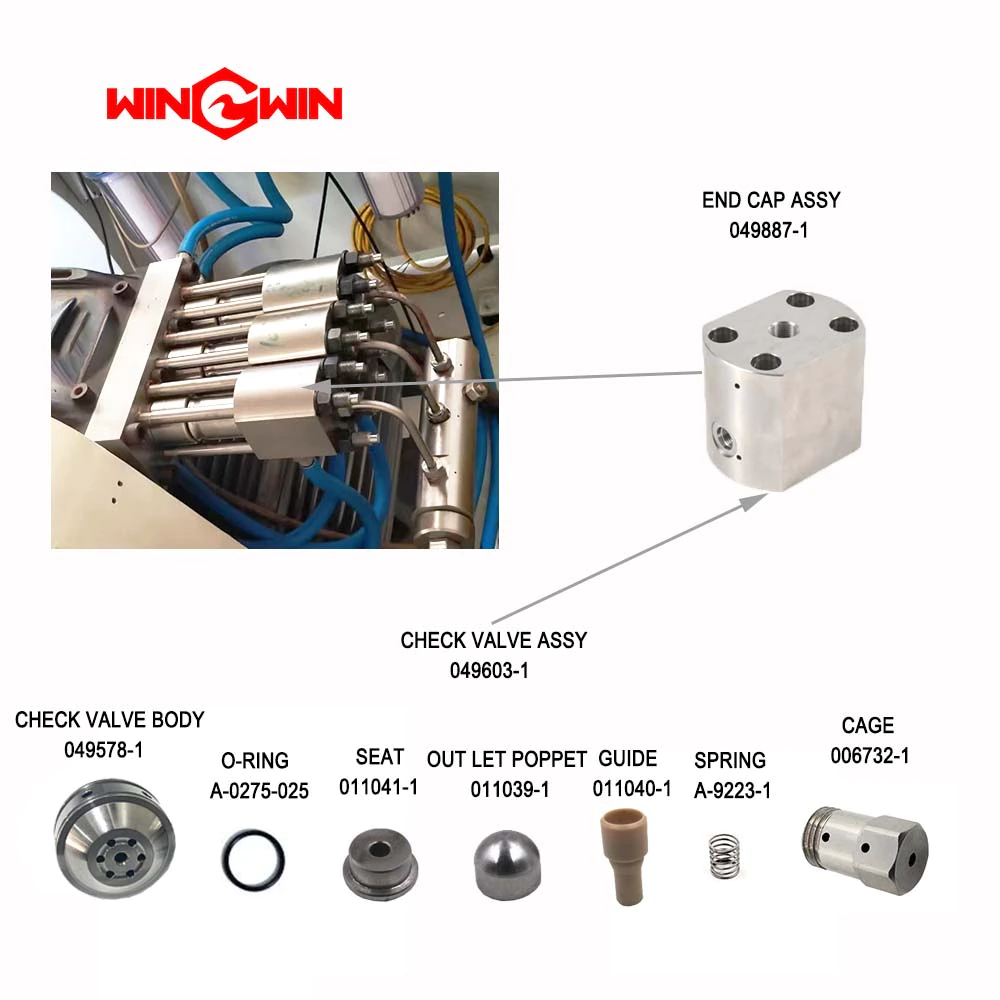

The working principle of the waterjet direct drive pump is the waterjet direct drive pump is driven to the crankshaft by an electric motor with a timing belt. The crank drives the three plungers in the cylinder. Each plunger/cylinder combination has a check valve that allows water to enter the cylinder during the back stroke of the plunger and forces water out into the high pressure line.