Descrição

Water Jet Accessories: Compression Spring 05147863

Application: 90,000 psi waterjet intensifier pump

Item | Part Number | Descrição | Quantity | Item | Part Number | Descrição | Quantity |

1 | 05146592 | Gasket, Topworks Support | 2 | 14 | 72162253 | Plunger | 2 |

2 | 20476377 | Support, Topworks | 2 | 15 | 05130091 | Hydraulic Seal Cartridge | 2 |

3 | 10118206 | O-Ring, 1.31×1.56× .13 | 2 | 16 | 72175989 | Flange do Retentor de Buchas | 2 |

4 | 05144514 | Hydraulic Cylinder | 1 | 17 | 72158494 | UHP Seal Assembly | 2 |

5 | 05098991 | Socket Head Screw, 3/8-16×3-3/4 | 8 | 18 | 72166738 | UHP Cylinder | 2 |

6 | 95688743 | Lock Washer, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Piston Assembly | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

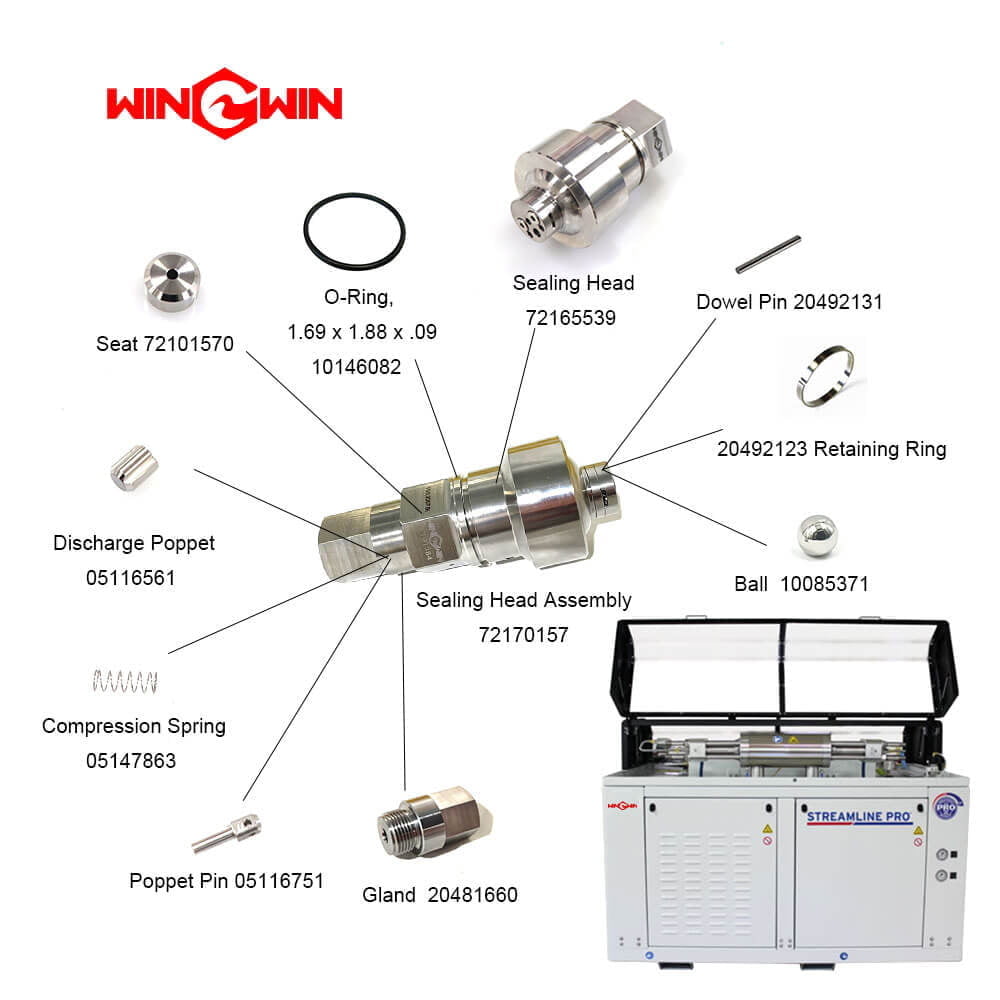

8 | 10074771 | O-Ring, 5.25×5.50× .13 | 2 | 21 | 72170157 | Sealing Head Assembly | 2 |

9 | 05120092 | Backup Ring, 5.25×5.50× .13 | 2 | 22 | 72178493 | Flange Assembly | 2 |

10 | 72175997 | Hydraulic Cylinder Head | 2 | 23 | 20464590 | Flat Washer, 1.13 | 8 |

11 | 05097886 | Socket Head Screw, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Hex Nut, 1-1/8-12 | 8 |

12 | 05144183 | Spacer Assembly, Proximity Switch | 2 | 25 | 20489339 | Adapter, JIC/Pipe, 50× .38 | 1 |

05144191 | O-Ring, .69× .88× .09 | 26 | 72176756 | O-Ring, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, Proximity Switch | 2 | ||||

| 72134224 | Interruptor de proximidade | ||||||

95119012 | Socket Head Screw, 1/4-20×1 |

Compression springs are a type of mechanical spring that are commonly used in high-pressure waterjet pumps, including those that operate at 90,000 psi.

These springs are designed to resist compressive forces, which makes them ideal for applications where there is a need to maintain a certain level of tension or force over time.

Here are some general characteristics of compression springs used in water jet accessories of 90,000 psi pumps:

1. Material composition

Compression springs used in water jet accessories of 90,000 psi pumps are typically made from high-strength materials such as stainless steel or other alloys that can withstand the high pressures and vibration of the pump.

2. Load capacity

The load capacity of a compression spring refers to the amount of force needed to compress the spring to a certain degree.

Compression springs used in water jet accessories of 90,000 psi pumps need to be able to withstand the high pressure of the water and the hydraulic fluid to ensure proper pump operation.

3. Wire diameter

The wire diameter of a compression spring used in a 90,000 psi waterjet pump refers to the thickness of the metal wire that makes up the spring.

The wire diameter can vary depending on the specific application and load capacity requirements of the spring.

4. Spring rate

The spring rate of a compression spring used in water jet accessories of a 90,000 psi pump refers to the amount of force needed to compress the spring by a certain distance.

A higher spring rate means that more force is required to compress the spring, which can help ensure that the spring maintains the desired level of tension or force over time.

5. Durability

Compression springs used in water jet accessories of 90,000 psi pumps need to be highly durable to withstand the extreme operating conditions of the pump.

This includes resistance to corrosion, fatigue, and wear and tear.

2. Heat treatment

Some compression springs used in water jet accessories of 90,000 psi pumps may undergo a heat treatment process to enhance their strength and durability.

This can involve heating the spring to a particular temperature, then cooling it rapidly to create a stronger, more durable material.

4. Stress relief

Compression springs used in water jet accessories of 90,000 psi pumps may undergo a stress relief process to help reduce the risk of failure due to fatigue or other factors.

This process involves heating the spring to a particular temperature, then slowly cooling it to help relieve any residual stresses in the material.

Compression spring is one of essential water jet accessories of the 90,000 psi pump, helping to maintain proper tension and force in the pump’s hydraulic system.

By choosing high-quality compression springs that are designed for use in high-pressure applications and following proper maintenance procedures, you can help ensure that your waterjet pump operates safely and efficiently over the long term.

Contact us for assistance.