Descrição

waterjet knowledge:about 94k waterjet parts and profitable waterjet cutting services

What materials can be cut with waterjet cutting machine ?

1. Waterjet cutting process for stones: There arises a variety of stone cutting machines, including large ones and small ones. When we purchase, we should distinguish whether it is for household use or professional use. The household one is easy to carry, and the power is small, which can reduce the workload of workers, and the power is small when the workload is small. Natural stone has high density and strong hardness, which is a type of hard material.Therefore, we has no alternative but to choose the waterjet cutting process. in this industry,use 94k waterjet machine,more cost-effective,our company provide 94k waterjet machines and 94k waterjet parts,

2. Waterjet cutting process for ceramic tiles: In the process of waterjet gasification cutting, the speed at which the surface temperature of the material rises to the boiling point temperature is so fast that it is sufficient to avoid heat conduction causing vaporization. As a result, some of the material tiles disappear as steam, and some of the material is blown away from the bottom of the cutting seam as ejecta by auxiliary gas flow. In this case, an excellent performanced power of waterjet cutting process is required. However, This processing cannot be used for materials such as wood and certain ceramics, which have no melting state and are unlikely to cause material vapor to condense again. Additionally, these materials typically require thicker cuts. In waterjet gasification cutting process, beam focusing depends on material thickness and beam quality. The power and gasification heat of the waterjet only have a certain impact on the focal position. When the thickness of the sheet is constant, the cutting speed is inversely proportional to the gasification temperature of the material. The required waterjet power density should be greater than 108W/cm2, and depends on the material, cutting depth, and beam focus position. Assuming sufficient waterjet power, the cutting speed is limited by the gas jet speed when the thickness of the plate is constant.our company provide 94k waterjet machines and 94k waterjet parts,

3. Waterjet cutting process for glass: Waterjet cutting process for glass belongs to cold cutting. Waterjet cutting process can be applied for a lot of fields, like cutting arcs and sharp corners, cutting any complex patterns on the plane. It is also fully numerically controlled, with higher efficiency and better quality. It is also generally used on craft glass. Moreover, there is no requirement to opening as cutting, and holes can also be punched. When cutting glass with Waterjet cutting process, the normal pressure of the waterjet mechine is 260-280MPA. If the pressure is too high, the glass will be cut and edge chipping will occur. The choice of cutting speed should be set according to the cutting surface.In the glass industry, 94k waterjet cutting machine is rarely used, and 94k waterjet parts are not required

4. Waterjet cutting process for foam: Since pure waterjet cutting is a cold cutting process, it is often used to cut some soft or thin materials, such as foam, fabric, cardboard, foil, rubber and wood. Waterjet cutting process needs to erode raw materials with fine water arrows. To cut a variety of materials from tool steel to titanium to foam, a granular (usually garnet) abrasive is added to the waterjet, which increases the cutting capacity. Switching between pure and abrasive waterjet cutting is simple thanks to the added abrasive at the nozzle. This flexibility enhances the versatility of the waterjet cutting process as it can easily switch from cutting 12.7mm foam spacers to 101.6mm titanium brackets.

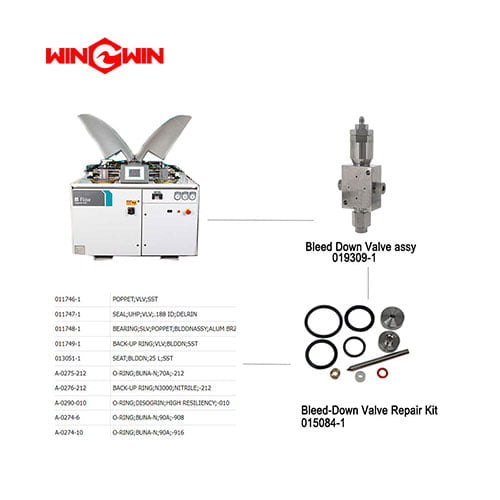

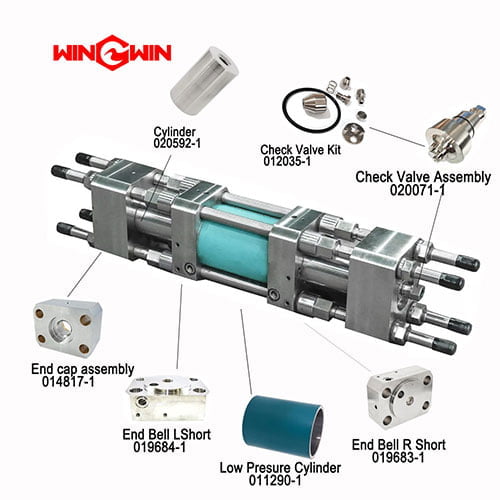

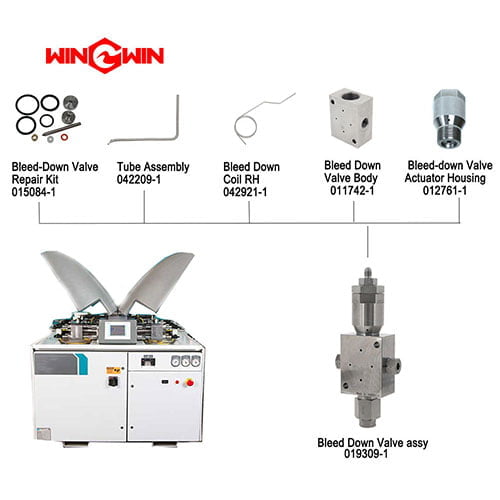

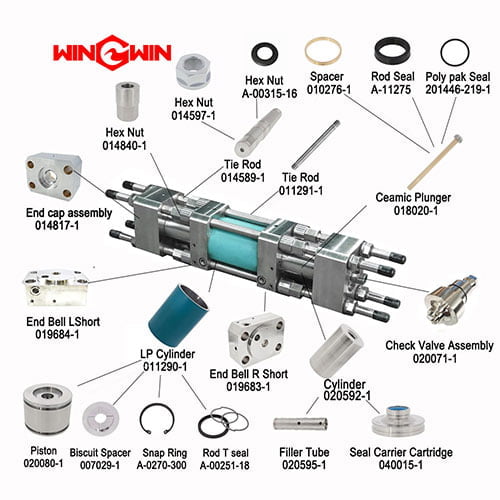

If you are using a 94k waterjet machine,you can contact our buy 94k waterjet parts,