Descrição

Parts for Water Pump: O-Ring, 3.88×4.25x.19 72176756

Item | Part Number | Descrição | Quantity | Item | Part Number | Descrição | Quantity |

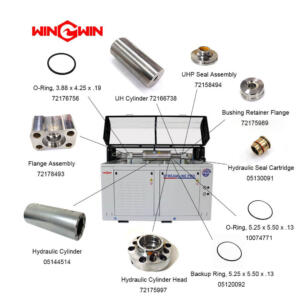

1 | 05146592 | Gasket, Topworks Support | 2 | 14 | 72162253 | Plunger | 2 |

2 | 20476377 | Support, Topworks | 2 | 15 | 05130091 | Hydraulic Seal Cartridge | 2 |

3 | 10118206 | O-Ring, 1.31×1.56× .13 | 2 | 16 | 72175989 | Flange do Retentor de Buchas | 2 |

4 | 05144514 | Hydraulic Cylinder | 1 | 17 | 72158494 | UHP Seal Assembly | 2 |

5 | 05098991 | Socket Head Screw, 3/8-16×3-3/4 | 8 | 18 | 72166738 | UHP Cylinder | 2 |

6 | 95688743 | Lock Washer, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Piston Assembly | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

8 | 10074771 | O-Ring, 5.25×5.50× .13 | 2 | 21 | 72170157 | Sealing Head Assembly | 2 |

9 | 05120092 | Backup Ring, 5.25×5.50× .13 | 2 | 22 | 72178493 | Flange Assembly | 2 |

10 | 72175997 | Hydraulic Cylinder Head | 2 | 23 | 20464590 | Flat Washer, 1.13 | 8 |

11 | 05097886 | Socket Head Screw, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Hex Nut, 1-1/8-12 | 8 |

12 | 05144183 | Spacer Assembly, Proximity Switch | 2 | 25 | 20489339 | Adapter, JIC/Pipe, 50× .38 | 1 |

05144191 | O-Ring, .69× .88× .09 | 26 | 72176756 | O-Ring, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, Proximity Switch | 2 | ||||

| 72134224 | Interruptor de proximidade | ||||||

95119012 | Socket Head Screw, 1/4-20×1 |

What are some common operating conditions that can affect the lifespan of the O-ring parts for water pump?

1. Pressure

The higher the pressure, the greater the stress on the O-ring parts for water pump. Operating a pump at high pressures can cause the O-ring to wear out faster.

2. Temperature

Exposing the O-ring to temperatures outside the specific range (extreme temperatures, either hot or cold) can cause the material to degrade or harden, leading to cracking or other damage.

In addition, rapid temperature changes can cause the O-ring to expand or contract, which can affect its sealing ability.

3. Chemical exposure

Exposure to chemicals or corrosive fluids can cause the O-ring material to break down or deteriorate over time.

4. Abrasion

O-rings can wear out faster if they come into contact with abrasive materials or surfaces. This can cause the material to become rough or pitted, which can affect its sealing ability.

In addition, abrasive particles can get trapped between the O-ring and the sealing surface, causing additional wear and tear.

5. Frequency of use

The more frequently a pump is used, the more wearand tear there will be on the O-ring. This will make the material degrade faster and require more frequent replacement.

In addition, if the pump is not used frequently enough, the O-ring can dry out and become brittle, which can also lead to cracks or other damage.

6. Installation

Correct installation of the O-ring parts for water pump is crutial to its performance and lifespan.

If the O-ring is not seated correctly or is installed in a damaged or dirty groove, it may not be able to seal properly.

This can cause leaks or other problems and can also cause the O-ring to wear out faster.

Contact us for assistance.