Descrição

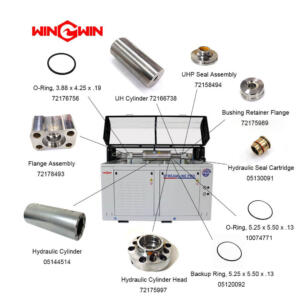

Flange Assembly 72178493 applied to 90k psi waterjet pump.

A flange assembly is a type of mechanical joint that connects two pipes or components together.

In the context of a 90k psi waterjet pump, a flange assembly is used to connect the pump to other parts of the waterjet system, such as the high-pressure hoses or the waterjet cutting head.

The flange assembly typically consists of a circular plate with bolt holes around the perimeter.

The plate is attached to one component, such as the pump, while the other component is attached to a matching plate with bolts.

The bolts are tightened to create a tight seal between the two components, preventing leaks and ensuring that the water pressure is maintained.

Item | Part Number | Descrição | Quantity | Item | Part Number | Descrição | Quantity |

1 | 05146592 | Gasket, Topworks Support | 2 | 14 | 72162253 | Plunger | 2 |

2 | 20476377 | Support, Topworks | 2 | 15 | 05130091 | Hydraulic Seal Cartridge | 2 |

3 | 10118206 | O-Ring, 1.31×1.56× .13 | 2 | 16 | 72175989 | Flange do Retentor de Buchas | 2 |

4 | 05144514 | Hydraulic Cylinder | 1 | 17 | 72158494 | UHP Seal Assembly | 2 |

5 | 05098991 | Socket Head Screw, 3/8-16×3-3/4 | 8 | 18 | 72166738 | UHP Cylinder | 2 |

6 | 95688743 | Lock Washer, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Piston Assembly | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

8 | 10074771 | O-Ring, 5.25×5.50× .13 | 2 | 21 | 72170157 | Sealing Head Assembly | 2 |

9 | 05120092 | Backup Ring, 5.25×5.50× .13 | 2 | 22 | 72178493 | Flange Assembly | 2 |

10 | 72175997 | Hydraulic Cylinder Head | 2 | 23 | 20464590 | Flat Washer, 1.13 | 8 |

11 | 05097886 | Socket Head Screw, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Hex Nut, 1-1/8-12 | 8 |

12 | 05144183 | Spacer Assembly, Proximity Switch | 2 | 25 | 20489339 | Adapter, JIC/Pipe, 50× .38 | 1 |

05144191 | O-Ring, .69× .88× .09 | 26 | 72176756 | O-Ring, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, Proximity Switch | 2 | ||||

| 72134224 | Interruptor de proximidade | ||||||

95119012 | Socket Head Screw, 1/4-20×1 |

Flange assemblies come in many different sizes and types, with variations in the number of bolt holes, bolt circle diameter, and other dimensions. It’s important to select a flange assembly that is compatible with the specific pump and system components being used.

When selecting a flange assembly for a 90k psi waterjet pump, it is important to choose a flange that is compatible with the pump’s specifications, such as its size, pressure rating, and material.

The flange assembly should also be designed to handle the high pressures and vibrations that are typical in waterjet cutting applications.

Flange assemblies are typically made from materials that can withstand high pressures and resist corrosion, such as stainless steel or high-strength alloys. The material selection is important to ensure that the flange assembly can withstand the harsh conditions of a waterjet cutting environment.

Flange assemblies must be installed correctly to ensure a tight seal and prevent leaks. This involves careful alignment of the two components being joined, as well as proper torqueing of the bolts to ensure that the flange assembly is secure.

Many flange assemblies are designed to be interchangeable, which means that different components can be easily swapped in and out of the waterjet system as needed. This can be useful for maintenance and repair purposes, as well as for customizing the waterjet system to meet specific cutting requirements.

In addition to flange assemblies, other types of mechanical joints may also be used in waterjet systems, such as threaded fittings or quick-connect couplings. The choice of joint type will depend on the specific needs of the system and the components being joined.

What are the common signs of wear or damage to look for when inspecting a flange assembly on a 90k psi waterjet pump?

1. Leaks

Leaks are the most obvious sign of wear or damage to a flange assembly. If you notice water or fluid leaking from the flange assembly, it may indicate that the gasket is worn or damaged, or that the bolts are loose or improperly torqued.

2. Corrosion or rust

Corrosion or rust on the flange assembly or bolts can indicate that the component is exposed to moisture or other corrosive fluids. This can weaken the flange assembly or the bolts, leading to leaks or failure.

3. Deformation or warping

If the flange assembly appears to be deformed or warped, it may indicate that it has been subjected to excessive pressure or heat. This can cause the flange assembly to fail or leak.

4. Loose bolts

If the bolts on the flange assembly are loose or out of alignment, it can cause leaks or damage to the flange assembly or the 90k psi waterjet pump components.

5. Gasket damage

The gasket material may become worn or damaged over time, leading to leaks or failure of the flange assembly.

6. Cracks

Any visible cracks on the flange assembly or bolts may indicate that the component is weakened and may fail under pressure.

It’s important to inspect the flange assembly regularly for signs of wear or damage and address any issues promptly to prevent further damage or downtime.

If you notice any of these signs, it may be necessary to replace the flange assembly or other components to ensure safe and efficient operation of the 90k waterjet pump.

What are the common causes of wear or damage to the flange assembly on a 90k psi waterjet pump?

1. Excessive pressure

The high pressures involved in waterjet cutting can cause wear or damage to the flange assembly over time. This can occur if the flange assembly is not designed to handle the specific pressure requirements of the 90k psi waterjet pump system.

2. Excessive vibration

If the flange assembly is exposed to excessive vibration, it can cause wear or damage to the bolts or other components over time. This can occur if the 90k psi waterjet pump or system components are not properly secured or if the system is not properly balanced.

3. Temperature fluctuations

If the temperature of the 90k psi waterjet pump system fluctuates significantly, it can cause wear or damage to the flange assembly or other components over time. This can occur if the system is not properly insulated or if the temperature control system is not functioning correctly.

4. Corrosive fluids

The fluids used in waterjet cutting can be corrosive, which can cause damage to the flange assembly or other components. This can occur if the flange assembly is not made from a corrosion-resistant material or if the fluids are not properly filtered or treated.

5. Misalignment

Misalignment of the flange assembly and 90k psi waterjet pump system components can cause wear or damage to the flange assembly over time. This can occur if the components are not properly aligned during installation or if the system undergoes vibration or movement during operation.

6. Improper installation

Improper installation of the flange assembly can cause wear or damage over time. This can occur if the bolts are not tightened to the correct torque specifications, if the gasket material is not installed correctly, or if the flange assembly is not properly aligned.

7. Age and use

The flange assembly will experience wear and damage over time with regular use. This can include wear or cracking of the bolts, deformation or warping of the flange assembly, or wear and tear on the gasket material.

By understanding the common causes of wear or damage to the flange assembly on a 90k psi waterjet pump, you can take steps to prevent these issues from occurring and ensure safe and reliable operation of the 90k psi waterjet pump system.

This may include upgrading components, improving maintenance procedures, or adjusting system parameters to address specific issues.

Any other questions, please fale conosco.