Descrição

Introduction

The O-Ring 10074565 is one of the essential waterjet machine parts applied to intensifier pumps operating at 90000 PSI.

As a black-colored nitrile rubber seal, it provides excellent resistance to oil, fuel, and other petroleum-based fluids.

This guide will provide a detailed description of the O-Ring 10074565, its features, benefits, and compatibility with waterjet machines.

It will also offer insights into proper installation, maintenance, and troubleshooting.

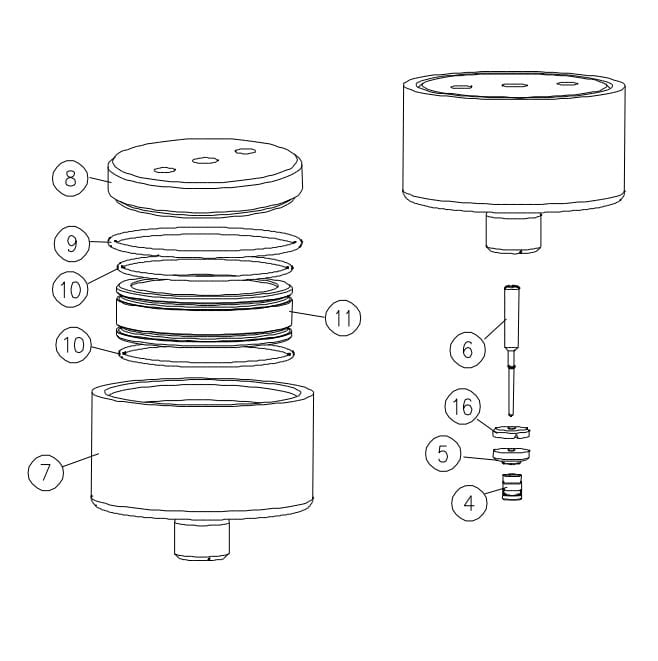

Item 10: 0074565 O-Ring, 2.25 x 2.38 x .06

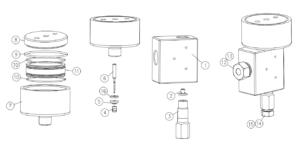

Item | Part Number | Descrição | Quantity | Item | Part Number | Descrição | Quantity |

1 | 20468617 | Valve Body | 1 | 9 | 10074714 | O-Ring, 2.44 x 2.63 x .09 | 1 |

2 | 10178697 | Valve Seat | 1 | 10 | 10074565 | O-Ring, 2.25 x 2.38 x .06 | 2 |

3 | 20451557 | UHP Adapter | 1 | 11 | BV501184 | Piston | 1 |

4 | 72112069 | Seal Assembly | 1 | 12 | 20452965 | UHP Collar, .38 | 1 |

5 | 20475874 | Backup Ring, Bronze | 1 | 13 | 20452956 | UHP Gland, .38 | 1 |

6 | 20475878 | Valve Stem | 1 | 14 | 20452959 | UHP Collar, .25 | 1 |

7 | 20468601 | Pneumatic Cylinder | 1 | 15 | 20452962 | UHP Gland, .25 | 1 |

8 | BV601184 | Cylinder Head | 1 | 16 | 20475882 | Backup Ring, SST | 1 |

| 20477518 | Spare Parts Kit | ||||||

| Includes items 2, 4, 5, 6, 9, 10 and 16 |

Features of O-Ring 10074565

The O-Ring 10074565 is a high-quality seal that is designed to withstand high-pressure applications.

Its dimensions are 2.25 x 2.38 x .06, making it an ideal choice for hydraulic and pneumatic systems in waterjet machines. Its features include:

– Resistance to oil, fuel, and other petroleum-based fluids

– Excellent abrasion resistance and tensile strength

– Durable and long-lasting

– Suitable for use in waterjet machines operating at 90000 PSI

Compatibility with 90000 PSI Waterjet Machines

The O-Ring 10074565 is designed to handle high-pressure applications and is compatible with waterjet machines operating at 90000 PSI.

Its resistance to oil and fuel, durability, and affordability make it an excellent choice for hydraulic and pneumatic systems in high-pressure waterjet machines.

Benefits of O-Ring 10074565 in Waterjet Machine Applications

1. High-Pressure Resistance

Waterjet machines that operate at 90000 PSI require components that can withstand high pressure and stress.

The O-Ring 10074565 is specifically designed to handle high-pressure applications, making it an ideal choice for use in waterjet machines.

2. Resistance to Oil and Fuel

The O-Ring 10074565 is made of nitrile rubber, which is highly resistant to oil, fuel, and other petroleum-based fluids.

This makes it an excellent choice for use in waterjet machines that rely on hydraulic and pneumatic systems to operate.

The O-ring’s resistance to oil and fuel ensures that the machine’s components remain functional and efficient during operation, preventing downtime and costly repairs.

3. Durability

The O-Ring 10074565 is known for its high tensile strength and abrasion resistance, making it a durable component in waterjet machines.

It can withstand continuous use and exposure to harsh environments without compromising its performance.

The O-ring’s durability ensures that it can withstand the wear and tear caused by the machine’s high-pressure operations, reducing the need for frequent replacements and maintenance.

4. Cost-Effective

The O-Ring 10074565 is an affordable component that provides excellent value for its cost.

Its durability and resistance to oil and fuel make it a cost-effective choice for use in waterjet machines, reducing the need for frequent replacements and maintenance.

The O-ring’s cost-effectiveness ensures that businesses can minimize expenses associated with machine maintenance and operations, improving their bottom line.

Proper Installation and Maintenance of O-Ring 10074565

Proper installation and maintenanceof the O-Ring 10074565 are essential to ensure optimal performance and longevity.

Here are some tips for proper installation and maintenance:

1. Compatibility

Ensure that the O-ring is compatible with the machine’s operating environment.

Check for compatibility with the hydraulic or pneumatic system’s fluid, temperature, and pressure requirements.

2. Compression and Stretch

The optimum range of compression for O-rings is typically 8% to 35%, with a reduced upper limit of 20% for dynamic seals.

The stretch for a smaller O-ring should not exceed 5%, and compression should not exceed 3% of the O-ring diameter.

The correct compression and stretch of the O-ring are crucial for providing an effective seal and preventing leakage.

3. Lubrication

Proper lubrication can prevent damage to the O-ring during installation and ensure optimal performance.

Use a compatible lubricant to prevent swelling or other forms of damage.

4. Regular Inspection

Regular inspection of the O-ring and other components can prevent leakage and failure, which can result in costly downtime.

Replace damaged or worn O-rings promptly to prevent further damage.

Causes of O-Ring Cracking

O-ring cracking can occur due to various factors, including ozone cracking, also known as ozonolysis.

Nitrile rubber O-rings, including Buna and Buna-N varieties, are particularly susceptible to ozone cracking.

Ozone cracking occurs when the O-ring is exposed to high temperatures, overly high compression, or other major stresses, causing it to lose its elasticity and become unable to return to its original shape.

This results in flat surfaces on both sides of the O-ring’s cross-section, making it unable to properly seal.

Troubleshooting O-Ring 10074565

If the O-Ring 10074565 is not sealing properly, it may be due to several reasons. Here are some troubleshooting tips:

1. Check for Compatibility

Ensure that the O-ring is compatible with the machine’s operating environment.

Check for compatibility with the hydraulic or pneumatic system’s fluid, temperature, and pressure requirements.

2. Check for Damage

Regular inspection of the O-ring and other components can prevent leakage and failure.

Check for signs of damage such as cracks, flat surfaces, or swelling. Replace damaged or worn O-rings promptly to prevent further damage.

3. Check for Compression and Stretch

The correct compression and stretch of the O-ring are crucial for providing an effective seal and preventing leakage.

Ensure that the compression and stretch of the O-ring are within the recommended range.

4. Lubrication

Proper lubrication can prevent damage to the O-ring during installationand ensure optimal performance.

Check that the O-ring is properly lubricated with a compatible lubricant.

Conclusão

In conclusion, the O-Ring 10074565 is a vital component in waterjet machines operating at 90000 PSI.

Its resistance to high pressure, oil, and fuel, along with its durability and affordability, make it a cost-effective choice for use in hydraulic and pneumatic systems.

Proper installation, maintenance, and lubrication can help ensure optimal performance and longevity, while regular inspection and replacement of damaged O-rings can prevent leakage and failure.

The compression and stretch of the O-ring during installation are crucial for providing an effective seal and preventing leakage.

Understanding the causes of O-ring cracking and troubleshooting tips can help prevent costly downtime and repairs.

At Win-Win, we offer a wide range of high-quality waterjet machine parts, including the O-Ring 10074565, to meet the needs of various industries.

Contact us to learn more about our 90000 PSI waterjet machine parts and how they can benefit your business.