Descrição

The Backup Ring 05129515 is one of the small 90000 psi pump parts used in high-pressure waterjet pumps.

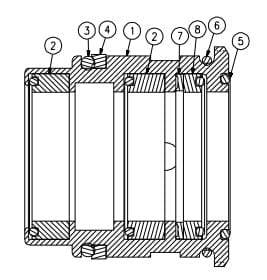

Item | Part Number | Descrição | Quantity |

1 | 05130109 | Seal Bushing | 1 |

2 | 05015060 | Packing Ring | 2 |

3 | 10193522 | O-Ring, 1.19 x 1.38 x .09 | 1 |

4 | 05050760 | Backup Ring | 1 |

5 | 05129481 | O-Ring, 1.0 x 1.13 x .06 | 1 |

6 | 05013024 | O-Ring, 1.25 x 1.38 x .06 | 1 |

7 | 05129515 | Backup Ring | 1 |

8 | 05027255 | Packing Seal | 1 |

| 80084759 | Rebuild Kit | ||

| Includes Items 2-8 |

Q: What are some common causes of wear or damage to the 90000 psi pump parts Backup Ring?

A:

1. Exposure to high pressure

The Backup Ring is designed to provide additional support and stability to O-Rings and other seals in high-pressure environments.

However, continuous exposure to high pressure can cause the Backup Ring to wear or become damaged over time.

2. Exposure to abrasive materials

Waterjet cutting applications often involve the use of abrasive materials such as sand, grit, or other particles.

These materials can cause wear or damage to the Backup Ring, especially if they are allowed to accumulate on the surface of the ring.

3. Improper installation

If the 90000 psi pump parts Backup Ring is not installed properly, it may become misaligned or damaged during operation.

4. Age

Like any other component of a waterjet pump, the Backup Ring can become worn or damaged simply due to age and normal wear and tear.

Over time, the Backup Ring may lose its elasticity or become brittle, making it more prone to damage.

5. Chemical exposure

Exposure to certain chemicals or fluids can cause the Backup Ring to become brittle or degrade over time.

It’s important to ensure that the Backup Ring is made from a material that is compatible with the fluids and chemicals used in your waterjet cutting application.

In addition to the causes mentioned above, here are other factors that can contribute to wear or damage to the Backup Ring.

Including exposure to extreme temperatures, improper handling or storage, and exposure to UV radiation or other environmental factors:

a. Perform regular cleaning and lubrication

Regular cleaning and lubrication of the components can help to prevent wear or damage to the Backup Ring and other 90000 psi pump parts.

This may include cleaning the pump and components with a mild detergent or solvent, and applying a high-quality lubricant to the Backup Ring and other seals.

b. Monitor the pump for leaks or changes in pressure

Regular monitoring of the waterjet pump can help to identify leaks or changes in pressure that may indicate a problem with the Backup Ring or other 90000 psi pump parts.

c. Store the Backup Ring properly

When not in use, the Backup Ring should be stored in a cool, dry place away from direct sunlight and other environmental factors that can cause it to degrade.

It’s important to ensure that the Backup Ring is stored in a way that prevents it from becoming misshapen or damaged.

Q: What are some maintenance tasks I can perform to prevent 90000 psi pump parts Backup Ring wear?

A:

1. Regularly inspect the Backup Ring

Regular inspections of the Backup Ring can help to identify signs of wear or damage before they become more serious.

2. Clean the components

Regular cleaning of the components can help to prevent wear or damage to the Backup Ring and other components.

Use a mild detergent or solvent to clean the pump and 90000 psi pump parts.

Be sure to remove any abrasive materials or debris that may have accumulated.

3. Lubricate the Backup Ring

Applying a high-quality lubricant to the Backup Ring and other seals can help to prevent wear or damage by reducing friction.

Be sure to use a lubricant that is suitable for the materials used in your waterjet pump.

4. Monitor the pump for leaks or changes in pressure

Regular monitoring of the waterjet pump can help to identify leaks or changes in pressure.

It may indicate a problem with the Backup Ring or other 90000 psi pump parts.

5. Store the Backup Ring properly

When not in use, the Backup Ring should be stored in a cool, dry place away from direct sunlight and other environmental factors that can cause it to degrade.

It’s important to ensure that the Backup Ring is stored in a way that prevents it from becoming misshapen or damaged.

6. Replace the Backup Ring at recommended intervals

Manufacturers typically recommend replacing the Backup Ring and other components at specific intervals to prevent wear or damage.

7. Use the correct tools and techniques

When performing maintenance on the waterjet pump, you should use the correct tools and techniques to prevent damage to the 90000 psi pump parts.

This may include using torque wrenches to ensure that bolts are tightened to the correct specifications, and using the correct lubricants and cleaning agents.

Any other questions about 90000 psi pump parts, please fale conosco.