Descrição

The Pneumatic Cylinder 20468601 is a type of cylinder that is commonly used in 90000 psi ultra high-pressure waterjet systems.

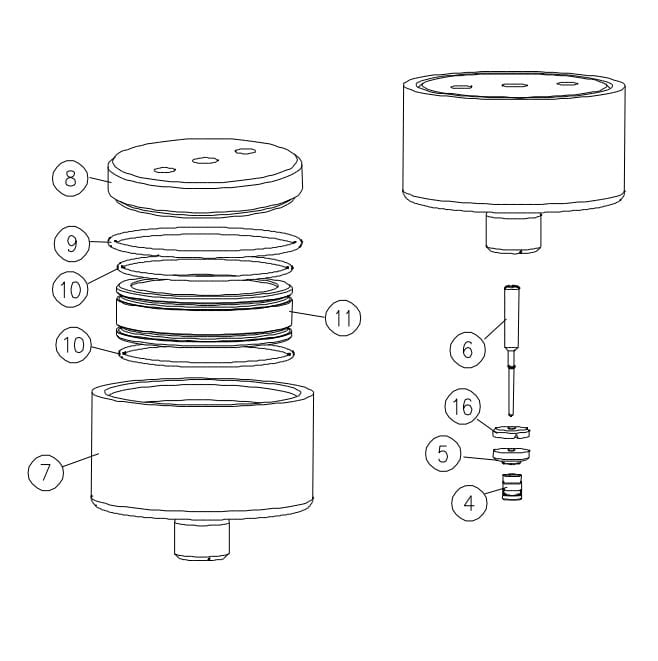

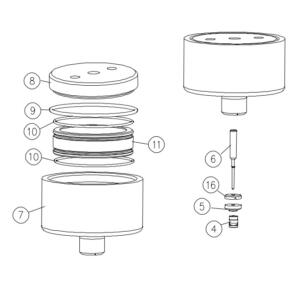

Item | Part Number | Descrição | Quantity | Item | Part Number | Descrição | Quantity |

1 | 20468617 | Valve Body | 1 | 9 | 10074714 | O-Ring, 2.44 x 2.63 x .09 | 1 |

2 | 10178697 | Valve Seat | 1 | 10 | 10074565 | O-Ring, 2.25 x 2.38 x .06 | 2 |

3 | 20451557 | UHP Adapter | 1 | 11 | BV501184 | Piston | 1 |

4 | 72112069 | Seal Assembly | 1 | 12 | 20452965 | UHP Collar, .38 | 1 |

5 | 20475874 | Backup Ring, Bronze | 1 | 13 | 20452956 | UHP Gland, .38 | 1 |

6 | 20475878 | Valve Stem | 1 | 14 | 20452959 | UHP Collar, .25 | 1 |

7 | 20468601 | Pneumatic Cylinder | 1 | 15 | 20452962 | UHP Gland, .25 | 1 |

8 | BV601184 | Cylinder Head | 1 | 16 | 20475882 | Backup Ring, SST | 1 |

| 20477518 | Spare Parts Kit | ||||||

| Includes items 2, 4, 5, 6, 9, 10 and 16 |

Specifically, it is often applied to 90000 psi waterjet intensifier pumps, which are used to generate extremely high pressure water streams for cutting.

When the 90000 psi pump is in operation, the pneumatic cylinder is used to control the flow of hydraulic fluid, which in turn controls the movement of the plunger.

The plunger is responsible for compressing water to extremely high pressures, and the pneumatic cylinder is used to control its movement and ensure that it operates smoothly and accurately.

This allows the pressure of the water to be regulated as needed.

The Pneumatic Cylinder 20468601 is designed to operate in high-pressure environments, and it is built to withstand the extreme pressures and forces that are generated in 90000 psi waterjet system.

It is typically made from high-strength materials like stainless steel or aluminum.

The Pneumatic Cylinder 20468601 is typically designed to operate with a specific pressure range, and it is important to ensure that it is properly rated for the specific application.

This is because operating the cylinder outside of its designed pressure range can lead to premature wear and failure, which can result in downtime and increased maintenance costs.

How does the Pneumatic Cylinder 20468601 compare to other types of cylinders?

The Pneumatic Cylinder 20468601 is a type of pneumatic cylinder, which is a device that converts compressed air into linear motion.

1. Power source

Pneumatic cylinders are powered by compressed air, which is a relatively inexpensive and widely available power source.

In contrast, hydraulic cylinders use hydraulic fluid, which can be more expensive and may require specialized equipment for handling and disposal.

Electric cylinders use electric motors, which may be more efficient but may require a power source and additional wiring.

2. Speed and force

Pneumatic cylinders are capable of generating high speeds and forces, making them suitable for applications that require fast and powerful linear motion, such as packaging or material handling.

Hydraulic cylinders are also capable of generating high forces, but may not be as fast as pneumatic cylinders.

Electric cylinders are generally slower and may not be as powerful, but are capable of more precise control over speed and force.

3. Maintenance requirements

Pneumatic cylinders are generally low-maintenance and require relatively simple maintenance tasks, such as lubrication and seal replacement.

Hydraulic cylinders may require more maintenance, such as fluid changes, while electric cylinders may require more complex maintenance tasks, such as motor repair or replacement.

4. Environmental considerations

Pneumatic cylinders are considered to be environmentally friendly, as they do not use hazardous fluids or generate electrical waste.

Hydraulic cylinders may use fluids that are hazardous to the environment and can be difficult to dispose of.

Electric cylinders may generate electronic waste and require a power source that may not be environmentally friendly.

5. Cost

Pneumatic cylinders are generally more cost-effective than hydraulic or electric cylinders, particularly for smaller applications.

Hydraulic cylinders may be more expensive due to the cost of hydraulic fluid and specialized equipment.

Electric cylinders may also be more expensive due to the cost of the motor and associated electronics.

6. Application suitability

The suitability of the Pneumatic Cylinder 20468601 or any other type of cylinder will depend on the specific application requirements.

Pneumatic cylinders are commonly used in applications that require high speeds and forces, while hydraulic cylinders may be more suitable for applications that require high precision or high load capacity.

Electric cylinders may be appropriate for applications that require precise control over speed and force.

What issues may occur while the Pneumatic Cylinder 20468601 is operating in 90000 psi pump?

Like any mechanical component, the Pneumatic Cylinder 20468601 can experience a range of issues over time, particularly if it is not properly maintained or operated outside of its designed parameters.

1. Leaks

Air or fluid leaks, which can occur due to worn or damaged seals or gaskets.

Leaks can reduce the effectiveness of the cylinder and lead to a loss of pressure or control.

2. Wear and tear

Over time, the moving parts of the cylinder can experience wear and tear, which can lead to reduced performance, increased friction, and decreased accuracy.

3. Overheating

If the cylinder is operated at too high a pressure or for extended periods of time, it can generate excess heat, which can cause damage to the seals and other 90000 psi components.

4. Contamination

Dust, dirt, and other contaminants can accumulate on the cylinder, which can cause damage to the seals and other components and lead to reduced performance or failure.

5. Improper installation

If the cylinder is not installed properly or is not aligned correctly, it can lead to uneven wear and damage to the cylinder or other 90000 psi components.

6. Misalignment

Misalignment can occur if the cylinder is not installed properly or if there is an issue with other components in the 90000 psi system.

Misalignment can cause uneven wear and tear on the cylinder, leading to reduced performance or failure.

7. Corrosion

Depending on the environment in which the 90000 psi waterjet system is operating, the Pneumatic Cylinder 20468601 may be exposed to corrosive elements, which can cause damage to the cylinder and other components.

8. Fatigue

Over time, the repeated cycles of operation can cause fatigue in the cylinder, which can lead to cracks, fractures, or other damage.

9. Improper lubrication

Proper lubrication is essential for the smooth operation of the cylinder.

If the cylinder is not lubricated correctly, it can lead to increased friction and wear on the moving parts, which can reduce the life of the cylinder.

10. Improper air supply

The Pneumatic Cylinder 20468601 relies on a supply of compressed air to operate.

If the air supply is insufficient or inconsistent, it can lead to reduced performance or failure of the cylinder.

You should regularly inspect and clean the cylinder, ensure proper alignment and lubrication, and use appropriate operating parameters, such as the correct air pressure and temperature.

Address any issues as soon as they arise, rather than waiting for them to become more serious problems.

If you do experience issues with the Pneumatic Cylinder 20468601, it’s often possible to repair or replace the cylinder, depending on the extent of the damage.

In some cases, it may be more cost-effective to replace the cylinder rather than attempt to repair it, particularly if the cylinder is approaching the end of its useful life.

Q: How can I know if the cylinder is aligned correctly?

A: Ensuring that the Pneumatic Cylinder 20468601 is properly aligned is important for preventing uneven wear and tear and other issues that can arise from misalignment.

1. Check the mounting bolts

The mounting bolts that secure the cylinder to the 90000 psi system should be tightened to the manufacturer’s specifications.

Loose bolts can cause misalignment or other problems.

2. Check the alignment of other components

Other components in the 90000 psi waterjet system, such as the intensifier pump and cutting head, should also be properly aligned.

Misalignment of these components can cause misalignment of the cylinder.

3. Check for signs of wear

Uneven wear on the cylinder or other 90000 psi components can be a sign of misalignment.

4. Measure the stroke length

If the stroke length is outside the recommended range, it may be a sign of misalignment.

5. Check for leaks

Leaks can be a sign of misalignment or other issues with the cylinder or other 90000 psi components.

If you notice any leaks, you should investigate the cause and address the issue promptly.

6. Use a dial indicator

A dial indicator is a precision measuring tool that can be used to measure the alignment of the cylinder.

The dial indicator is mounted to a fixed point on the system, and the measuring tip is placed against the cylinder.

As the cylinder is moved, the dial indicator will show any deviations from the correct alignment.

7. Check for parallelism

The Pneumatic Cylinder 20468601 should be mounted in a position that is parallel to the other components in the 90000 psi system.

To check for parallelism, measure the distance between the cylinder and other components at several points along their length.

If the distances are not consistent, it maybe on account of misalignment.

8. Check for angular misalignment

Angular misalignment can occur if the cylinder is not mounted at a right angle to the other components in the 90000 psi system.

To check for angular misalignment, measure the angle between the cylinder and other components using a protractor.

9. Check for concentricity

Concentricity refers to the degree to which the cylinder is centered on the axis of rotation.

To check for concentricity, measure the distance between the cylinder and the axis of rotation at several points around the cylinder.

If the distances are not consistent, it may be due to misalignment.

10. Use laser alignment tools

Laser alignment tools can be used to quickly and accurately measure thealignment of the Pneumatic Cylinder 20468601.

These tools use laser beams to measure the position and alignment of the cylinder and other components in the 90000 psi system.

Laser alignment tools can offer precise measurements and are usually used in industrial settings where precision is critical.

Any other questions about 90000 psi waterjet pumps or other components, please fale conosco.