Descrição

Robot Waterjet Cell Parts

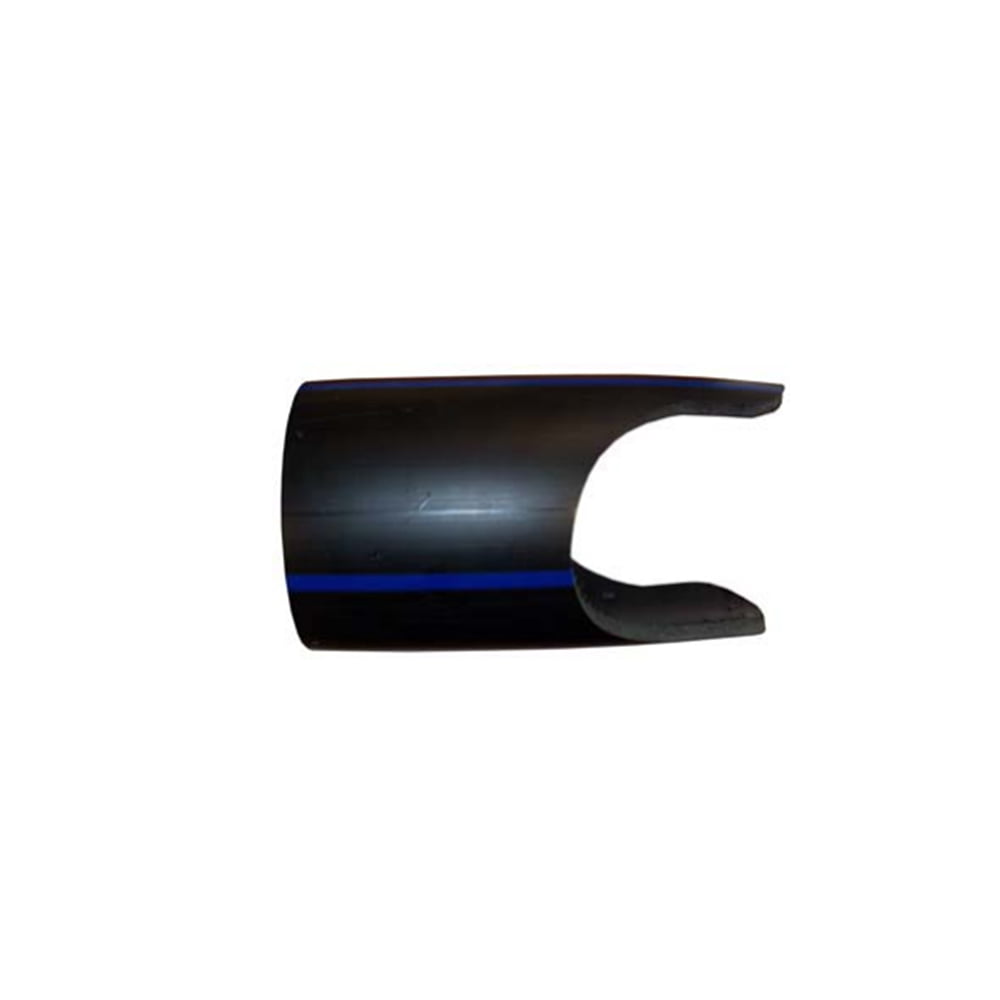

Item number: 304409 Coil Protection

Detalhes: usado nos braços robóticos da ABB, estação de trabalho robótica de corte com jato de água

Win-Win provide robot waterjet solutions, robot waterjet cell parts, etc.

Related robot waterjet cutting workstation & peças de célula de jato de água robô:

Robótico sistema de corte por jato de água & Robot Waterjet Cell Parts: Yaskawa robotic waterjet workstation and Robot Waterjet Cell Parts, Dual Fanuc robotic waterjet workstation and robot waterjet cell parts , ABB robotic waterjet workstation and robot waterjet cell parts.

FAQ of platform waterjet machine & robot waterjet system & peças de célula de jato de água robô:

1, Can Water Jet Cutting Machine be used for perforating fragile materials?

Yes, water jet cutting machine can be used for perforating fragile materials. Water jet cutting is a technology that utilizes a high-speed jet of water to cut materials. It creates a high-speed stream of water on the material, which cuts or perforates the material through the impact and abrasion of the water.

Compared with traditional mechanical cutting methods, water jet cutting has some unique advantages. Firstly, water jet cutting does not create a heat affected zone around the material as the cooling effect of the water reduces the risk of thermal deformation and cracking. This is important for fragile materials, which are often very sensitive to temperature changes.

Secondly, water jet cutting allows for high precision cutting and punching. Water jet cutting machines can control the speed and pressure of the water stream to achieve the different shapes and sizes of holes required. This is useful for fragile materials that require precise hole sizes and shapes.

Additionally, water jet cutting can be used for various types of fragile materials such as glass, ceramics and stone. This is because water jet cutting does not require the use of cutting tools and avoids stress concentration on the material, thus reducing the risk of material breakage.

In conclusion, water jet cutting machines are an ideal technology for perforating fragile materials, allowing for high precision and low damage cutting results.

2, What do I need to be aware of when using a water jet cutting machine for perforating fragile materials?

When using a water jet cutting machine for perforating fragile materials, the following points need to be noted:

Material fixation and support: Fragile materials may be subjected to the impact and pressure of the water flow during the perforation process, so it is necessary to ensure that the material is well fixed and supported. Suitable clamps or braces can be used to secure the material to prevent it from moving or breaking.

Water flow speed and pressure control: Water jet cutting machines can regulate the speed and pressure of the water flow. For fragile materials, the proper water flow speed and pressure need to be carefully selected to avoid excessive impact and abrasive effects that can cause the material to break.

Hole Size and Shape: Water jet cutting can fulfill the need for punching holes of different shapes and sizes. When choosing the hole size and shape, the characteristics and strength of the material need to be considered to ensure that the drilling is completed without damaging the material.

Cooling and Cleaning: Heat is generated during the water jet cutting process and it is important to cool the fragile material, which can be achieved by spraying coolant on the cutting area or using a cooling system. In addition, the surface of the material needs to be thoroughly cleaned after punching to remove any residual cutting agent and debris.

Experimentation and commissioning: Before proceeding with a formal perforating operation, experimentation and commissioning is recommended. Tests can be conducted with similar materials or scrap to determine the optimum water flow rate, pressure and other parameters, as well as to verify the effectiveness of the perforation.

Professional operation and protective measures: Water jet cutting machines are high-pressure equipment that require strict adherence to operating guidelines and safety regulations when in operation. Operators should wear appropriate personal protective equipment such as safety glasses, gloves and protective clothing.

By taking care of the above, you can ensure that the task of perforating fragile materials with a water jet cutting machine is completed safely and efficiently, and that the risk of material damage is minimized.

3, What other types of materials are water jet cutting machines used to perforate?

Water jet cutting machines are suitable for punching holes in many types of materials, including but not limited to the following categories:

Metal materials: water jet cutting can be used to perforate a variety of metal materials such as steel, aluminum, copper, stainless steel and more. It can handle metal materials with different thickness and hardness and achieve high precision hole diameter and shape.

Stone and rock: Water jet cutting is suitable for perforating stone and rock, such as marble, granite, limestone and so on. It can realize fine cutting and perforation on these materials for construction, carving and decoration.

Glass and Ceramics: Water jet cutting is widely used for perforating and cutting glass and ceramic materials. It can realize high-precision and smooth holes, and is suitable for processing glass plates, glass bottles, ceramic tiles and other products.

Plastics and composites: Water jet cutting can be used for punching holes in various plastics and composites, such as polyurethane, polypropylene, and fiber-reinforced plastics. It can realize fine cutting effect and is suitable for automotive, aerospace, electronics and other industries.

Rubber and Foam Materials: Water jet cutting is suitable for perforating and cutting rubber and foam materials, such as rubber sheets, foam sheets, etc.. It allows for accurate hole sizes and shapes for making seals, soundproofing materials and more.

Wood: Water jet cutting can be used for perforating and cutting wood. It can realize fine cutting effect and is suitable for processing of wooden furniture, handicrafts and so on.

It should be noted that different materials have different characteristics and cutting requirements, so when using a water jet cutting machine for perforation, the water flow rate, pressure and other parameters may need to be adjusted to achieve the best cutting results.