Description

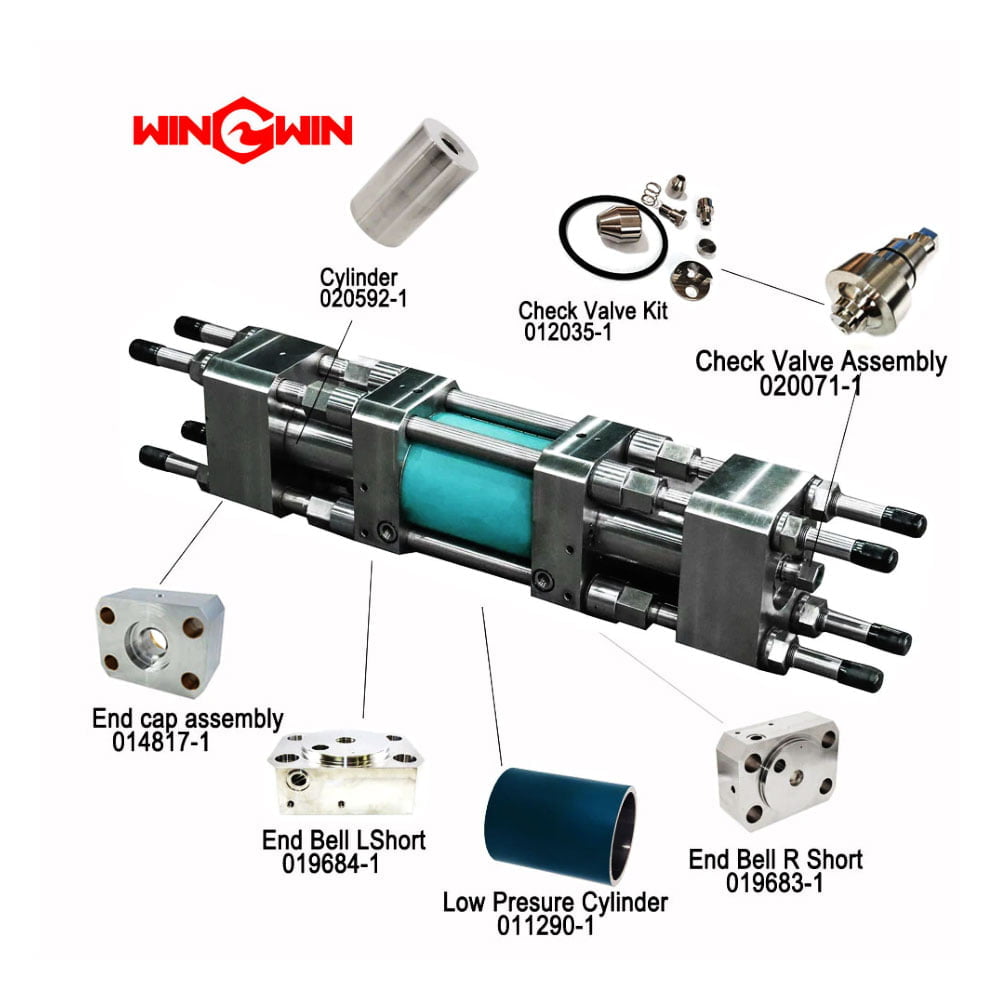

Waterjet supplier 019683-1 End Bell Intensifier Right Hand

WINWIN Waterjet supplier cutting machine, whose cutting efficiency has increased by 50%. 90,000psi ultra-high pressure equipment can make the cutting speed of water up to 50%, oil-immersed stainless steel has a double sealing structure, thick lead screw, large slider, meanwhile its transmission accuracy can reach by ±0.02mm, WINWIN waterjet cutting machine has ten years of achievements in new technology research and development, especially the new generation of ultra-high pressure water cutting machine. We strongly recommend that Waterjet supplier should choose our WINWIN waterjet.

Although there exist various larger Waterjet supplier, WINWIN Co., Ltd. has accomplished a lot of large-scale water cutting projects. For example, glass industry water cutting projects, which needs a multi-head structure. As we all know, water cutting is a cold processing method, no heat effect, whose can cut 3mm thick glass to more than 200mm thickness of glass. A processing plant in Brazil is specialized in the production of glass enterprises that possessed with five glass production lines, all of them are adopted the Multi-head batch cutting structure.

However, Waterjet supplier choose to select WINWIN high-flow equipment and 90,000psi ultra-high pressure equipment. The large-flow equipment can drive three cutter heads at the same time, as mass production glass utlization. More importantly, 90,000psi ultra-high pressure water cutting equipment for cutting 230mm thick custom glass, Meanwhile, the overall scheme consists of a total of five sets, from the early drawing check to the later after-sales installation. The entire water cutting project covers an area of more than 3000 square meters, the water cutting platform has a total of 5 sets, such as 12mx3m water cutting platform, 1mx5m water cutting platform, etc., Nowadays, the current project is perfectly completed and put into production excellently.

A processing factory in the United States is a manufacturer specializing in waterjet cutting, laser cutting, plasma cutting, stainless steel processing, stainless steel special-shaped parts processing, stainless steel engineering production. A manufacturer integrating stainless steel engineering production and installation, its main business are:

- Waterjet cutting processing, laser cutting processing, plasma cutting processing, CNC / flame plasma cutting.

- Stainless steel products: such as tableware, carts, workbenches, oil tanks, mixers, fire tanks, water tanks, environmental protection garbage containers, community mailboxes, stainless steel shelves, etc., such as medical equipment, hotels, sanitary food and other industrial special machinery parts processing.

- Stainless steel engineering installation shear plate, brushed gusset, gross, stainless steel footline, door set, shed, canopy gusset, various closures, steel structure, iron engineering, stainless steel canopy. 4. Professional barring works, including: ordinary railings, different models of home decoration railings, etc.

Waterjet supplier cutting can cut 300mm thick titanium alloy. Up to now, the newest technology in the world is 90,000psi ultra-high pressure water cutting booster pump. However, who can produce this ultra-high pressure water cutting equipment waterjet supplier are two companies, meanwhile their products’ principles and core components are universal. Fortunately, WINWIN Co., Ltd. has the capability to solve water cutting problems for customers, focusing on design and development and waterjet supplier provide cutting solutions, especially in the military industry, whose inspiration is water cutting.

Banks, homes and organizations, all of which must possess with a higher security. Therefore, bulletproof glass is too safe to protect you from shooting accident. However, water cutting is not only a complicated process but also can be easily injured if not cut properly. Moreover, if poorly handled, beautiful gemstones inside would be frequently worn out, resulting in abrasions or poor results. However, waterjet cutting process is a smooth, clean and precise cutting solution! With waterjet cutting you will get a perfectly smooth cutting effect on shops or museums. You won’t understand how powerful, efficient, and precise these machines are until you see a video of how waterjet the motorcycle helmets molded by waterjet cutting! Waterjet cutting process allows cutting every components at once, with the same precisions and commitments to details. I strongly hope that your chices to Waterjet supplier will show you all of these conditions!

Waterjet supplier can reduce the failure of your equipment and improve your production efficiency