Description

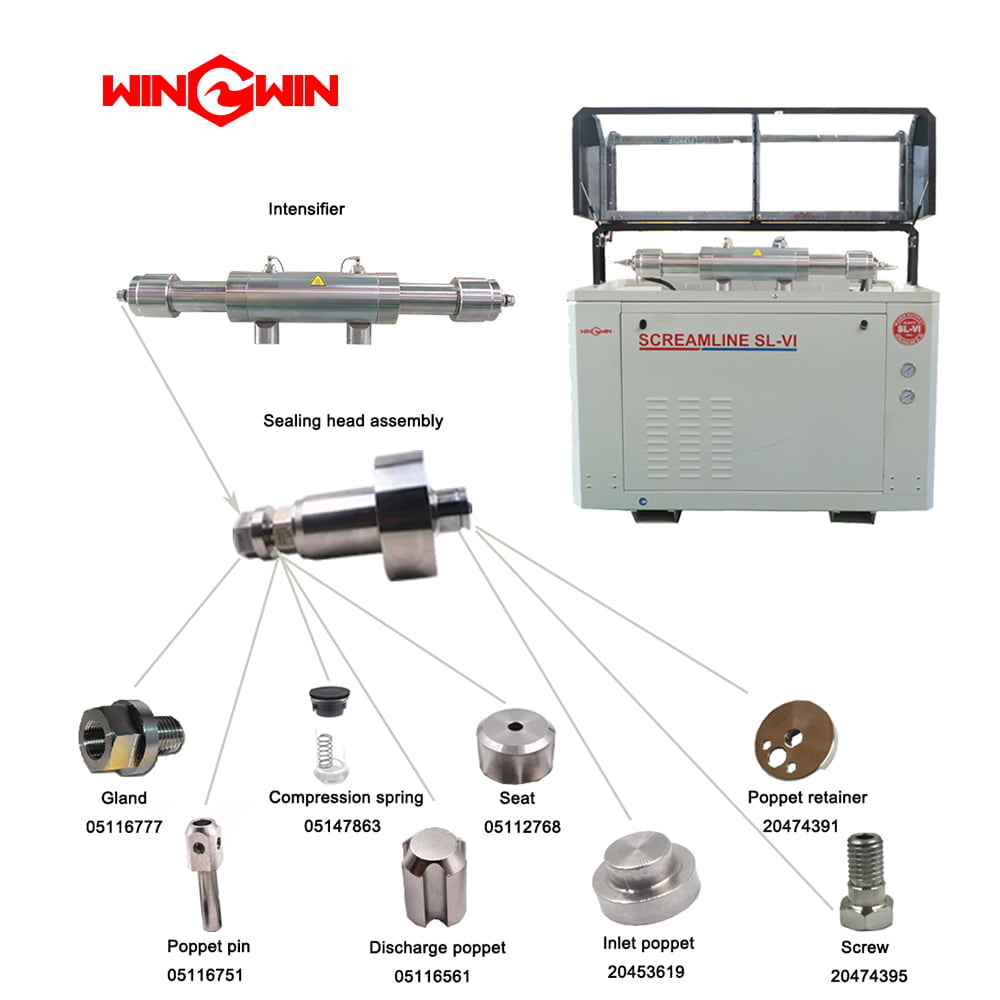

Waterjet parts 72142526 is the sealing head assembly that used on SL-VI 60k intensifier pump. The whole set sealing head assembly include: 05133335 discharge check valve repair kit, 05116751 poppet pin, 05116561 discharge poppet, 20453619 inlet poppet, 05112768 high pressure seat, 05147863 compression spring, 20474391 poppet retainer and also the screw 20474395, and also the gland 05116777; it connected with the water jet cylinder nut 80073646.

This type water jet sealing head assembly can support 60k psi working pressure.

The weight of the sealing head assembly is about 3.5 kgs, Win-Win waterjet as the waterjet parts suppliers, we have all these parts in stock.

No matter direct drive pump or hydraulic water jet intensifier pump both need the sealing head assembly. It’s the core device of the water jet cutting system, the working principle of the water jet cutting machine is : to convert the pressure energy of the water to kinetic energy, and the high pressure generating equipment (water jet intensifier pump) is pressurized to obtain huge energy, forming a high speed water jet. Which is sprayed on the surface of the workpiece. When the water jet impacts the workpiece to be cut, if the pressure can exceed the breaking strength of the cutting material such as metal, stainless steel, glass, stone, marble etc. the material can be cut off to achieve the processing purpose of removing the material.

One of the key benefits of using the water jet abrasive cutting machine to cut is its ability to cut through materials without any heat generated. This makes it an ideal cutting method for materials that are sensitive to heat such as plastics and composites. Additionally, the waterjet cutting process does not produce any hazardous fumes or dust, which makes it a safer cutting method compared to other cutting methods such as laser cutting or plasma cutting.

In terms of maintenance, the waterjet sealing head assembly requires regular maintenance to ensure that it continues to operate at peak efficiency. This includes regular inspection and replacement of waterjet parts such as the high pressure poppet and seat etc. The sealing head body normally can be used about one to two years.

There are many brands of waterjet parts intensifier pump spare parts and also water jet cutting head parts you can find in Win-Win Waterjet Company. Want to know more information, feel free to leave your message.