Description

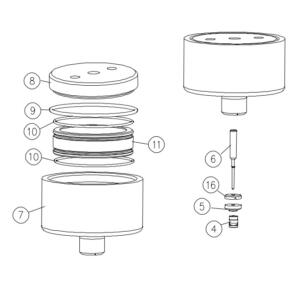

Item number : 05086905

Description: waterjet parts conduit, used on the 100hp waterjet high pressure pump

FAQ of Waterjet Cutting Industry:

What are the parts of the waterjet cutting machine?

A waterjet cutting machine is a complex system composed of several key components that work together to cut materials accurately using a high-pressure waterjet. Here are the main parts of a typical waterjet cutting machine:

- High-Pressure Pump – waterjet parts: The high-pressure pump is the heart of the waterjet system. It pressurizes water to extremely high levels (typically between 40,000 to 90,000 psi) to create the cutting force. There are two main types of pumps used in waterjet cutting machines: intensifier pumps and direct-drive pumps.

- Water Reservoir – waterjet parts: A water reservoir stores the pressurized water before it is sent to the cutting head. It helps maintain a consistent water supply to the cutting process.

- Cutting Head – waterjet parts: The cutting head is the business end of the waterjet system. It includes a nozzle through which the high-pressure water or water mixed with abrasive material is expelled to create a fine, high-velocity jet for cutting. The cutting head is designed to be precise and to focus the jet on the material being cut.

- Abrasive Mixing System (Optional): In abrasive waterjet cutting, an abrasive material, such as garnet, is mixed with the high-pressure water to increase cutting efficiency and precision. The abrasive mixing system handles the blending and delivery of abrasive material into the water stream.

- CNC Controller – waterjet parts: The CNC (Computer Numerical Control) controller is the brain of the waterjet cutting machine. It interprets computer-aided design (CAD) or computer-aided manufacturing (CAM) files and precisely controls the movement of the cutting head along the X, Y, and Z axes. This ensures accurate cutting according to the programmed design.

- X-Y Table: The X-Y table provides the mechanical framework for the cutting head’s movement. It allows for precise positioning of the workpiece in relation to the cutting head. Some waterjet machines also have a Z-axis for vertical movement.

- Catch Tank – waterjet parts: The catch tank collects the water and abrasive mixture after it has passed through the material being cut. It separates the abrasive for reuse and filters the water, making it more environmentally friendly.

- High-Pressure Lines – waterjet parts: High-pressure lines carry the pressurized water from the pump to the cutting head. These lines are specially designed to withstand the extreme pressure of the water.

- Control Panel: The control panel provides an interface for the operator to set cutting parameters, control the machine, and monitor the cutting process.

- Cooling System – waterjet parts: Waterjet systems generate heat during operation, so a cooling system is used to maintain the optimal temperature of the components, particularly the pump.

- Garnet Removal System (Optional) – waterjet parts: In systems that use abrasive, a garnet removal system is used to separate and recycle the abrasive material, reducing waste and cost.

- Safety Features: Waterjet cutting machines are equipped with safety features such as emergency stop buttons, safety interlocks, and protective covers to ensure operator safety during operation.

These are the primary waterjet parts of a waterjet cutting machine, and their efficient collaboration allows for precise and versatile cutting of a wide range of materials. The specific configuration and features of a waterjet machine may vary depending on the manufacturer and the intended application.