Description

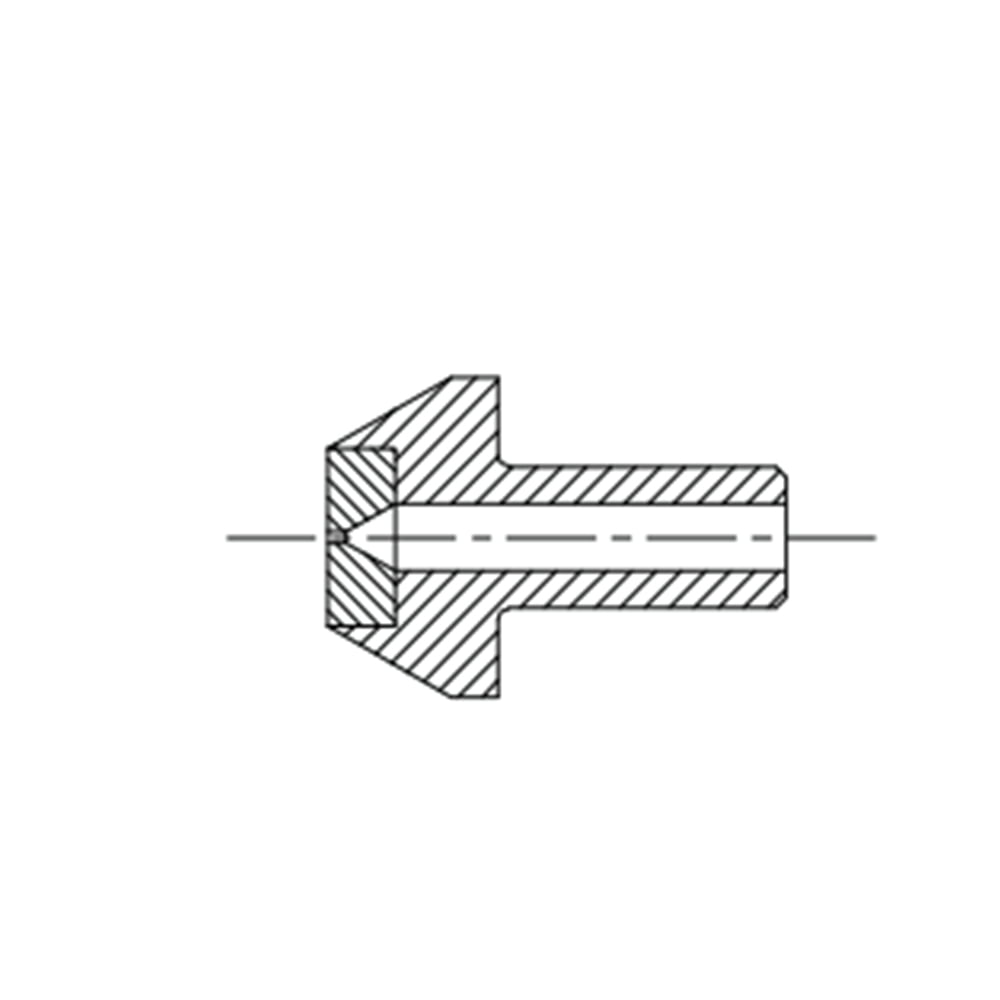

The waterjet orifice is used on the waterjet cutting head, normally installed in the waterjet mixing chamber. There are many sizes of waterjet orifice, the inner diameter that used on the abrasive waterjet cutter is relative larger. Common waterjet orifice has three materials: Ruby orifice, sapphire orifice and diamond orifice, as following picture showed:

Related waterjet orifice:

| Item Number | Description | Item Number | Description |

| A2260001 | 0.001″(0.025mm) | A2260013 | 0.013” (0.330 mm) |

| A2260002 | 0.002″(0.051mm) | A2260014 | 0.014″ (0.356 mm) |

| A2260003 | 0.003″(0.076mm) | A2260015 | 0.015″ (0.381 mm) |

| A2260004 | 0.004″(0.102mm) | A2260016 | 0.016″ (0.406 mm) |

| A2260005 | 0.005″(0.127 mm) | A2260018 | 0.018″ (0.457 mm) |

| A2260006 | 0.006″ (0.152 mm) | A2260019 | 0.019” (0.483 mm) |

| A2260007 | 0.007″ (0.178 mm) | A2260020 | 0.020″ (0.508 mm) |

| A2260008 | 0.008″ (0.203 mm) | A2260021 | 0.021” (0.533 mm) |

| A2260009 | 0.009″ (0.229 mm) | A2260022 | 0.022″ (0.559 mm) |

| A2260010 | 0.010″ (0.254 mm) | A2260024 | 0.024” (0.610 mm) |

| A2260011 | 0.011” (0.279 mm) | A2260028 | 0.028” (0.711 mm) |

| A2260012 | 0.012″ (0.305 mm) | A2260032 | 0.032” (0.813 mm) |

FAQ of the waterjet orifice & waterjet cutting machine:

What is a waterjet orifice?

A waterjet orifice is a waterjet consumable used on the waterjet cutting head of the waterjet cutting machine. The installation location is located inside the mixing chamber of the waterjet head. There will be a place for the waterjet orifice. The ultra-high-speed flowing water flowing through the small aperture of the waterjet orifice enters the interior of the waterjet mixing chamber and fully mixes with the abrasive into the waterjet mixing tube to realize the cutting function of the workpiece. Therefore, waterjet orifice is also an indispensable part of the water jet cutting machine, and it is also a product in the category of wearing parts, which needs to be replaced regularly by the maintenance personnel of the machine.

What material is used for waterjet orifce?

There are three common materials for Waterjet orifice:

1. ruby orifice: It is a relatively common material, the most common in water jet machines. It is the most affordable orifice among the three materials. This orifice is made of high-strenght and high-hardness material – synthetic ruby, which has the characteristics of wear resistance and corrosion resistance. It is a waterjet orifice that is widely liked by customers.

2. Sapphire orifice: It is also a relatively common waterjet orifice. It also has all the characteristics of Ruby orifice, such as wear resistance and corrosion resistance, and sapphire orifice has better expressive power and is more durable. Of course, the price is higher than ruby orifice out a little bit.

3. diamond orifice: This is the most expensive product among the three orifices we are talking about. Everyone knows that diamond is the hardest material in the world, and it is also wear-resistant and corrosion-resistant, and its wear resistance is much higher than the other two ordinary orifices. Lifespan is the other two gemstones. Dozens of times or even nearly a hundred times as much. Of course, the price of a diamond orifice is several times that of the other two orifices.

How much does the waterjet orifice cost?

Regarding the price of waterjet orifice, I think it is a question that much water jet machine users are interested in. The specific price will vary depending on the brand, material, and model of orifice, and the price difference is also very large. The price of ruby orifice made of ordinary materials is generally around 5-20 US dollars, and the price of diamond orifice made of very good materials is usually above 300 US dollars. If you want to know the specific model or size, you can contact us.

What’s the service life of waterjet orifice?

There are many factors that affect the service life of waterjet orifice, such as the water quality of the machine’s working place, the use of water filter elements, the installation method of the installer, whether the concentricity of orifice and nozzle can be maintained, etc., etc., will affect the specific use time. . According to our many years of experience in the field of water jetting, the common waterjet orifice is generally used for about 20–60 hours. This data is for ruby orifice; if it is a diamond orifice, the usage time is about 1200-1800h. The above data For reference, it is necessary to consult professional staff to give a conclusion based on the actual situation.

How to choose the right waterjet orifice?

How to choose a suitable waterjet orifice, try to choose a reputable waterjet supplier. Generally, experienced waterjet manufacturer sales staff can provide pertinent professional advice. If you are an initial customer who is not very familiar with waterjet machines, you can avoid buying the wrong one. Condition. When choosing waterjet orifice, you need to be able to know the specific applicable brands, such as the well-known water cutting brands kmt, flow, etc.; such as these big brands of water jet machine accessories have corresponding numbers, and it is very accurate to purchase according to the number of;

If it is a niche brand that does not know the product number, it is also possible to purchase a suitable product by providing the product’s picture, size, inner diameter, etc.

Or you can also tell the supplier what product your water jet machine is used for cutting, etc., and they will recommend suitable products based on experience, including the size of orifice and nozzle can basically be determined.

How to replace a waterjet orifice?

Before replacing the waterjet orifice, it is necessary to stop the machine and release the high-pressure water before operating it. Disassemble the relevant accessories, such as mixing chamber and nozzle body, etc., check whether there is any problem with the relevant parts, and install a new orifice for testing after confirming that it is correct.

When installing the orifice, it is necessary to ensure that the orifice and the nozzle are concentric, otherwise it is easy to cause wear of these two parts or even cut the workpiece.

What is the minimum hole diameter for a waterjet?

The minimum aperture of waterjet orifice is about 0.001″, and orifice with small aperture size is often used in water-guided laser machines or waterjet only cutting machines. Generally, the orifice aperture required by an abrasive waterjet cutting machine will be larger than that of pure waterjet machine.

What is the hole tolerance on a waterjet?

The hole tolerance on a waterjet depends on several factors, including the cutting parameters, material being cut, nozzle size, and desired cutting precision. Waterjet cutting is generally known for its accuracy and ability to achieve tight tolerances. However, it’s important to note that achieving precise hole tolerances with waterjet cutting may have limitations compared to other machining methods such as milling or laser cutting.

The typical hole tolerances that can be achieved with waterjet cutting range from ±0.1 mm (±0.004 inches) to ±0.5 mm (±0.020 inches), but it can vary based on the specific conditions and requirements of the cutting process.

Several factors can influence the achievable hole tolerance in waterjet cutting:

Material: Different materials have varying characteristics and may behave differently during the cutting process. Harder materials may offer better dimensional accuracy compared to softer or more brittle materials.

Nozzle Size: The size of the waterjet cutting nozzle can affect the achievable hole tolerance. Smaller nozzle sizes generally allow for finer control and higher precision.

Cutting Speed: The cutting speed, or traverse rate, can impact the hole tolerance. Higher cutting speeds may result in slightly looser tolerances compared to slower cutting speeds.

Material Thickness: Thicker materials may introduce more variations in the hole tolerance due to factors like material warping or stream lag.

Cutting Technique: The cutting technique used, such as through-hole cutting or edge-start cutting, can also influence the achievable hole tolerance.

For waterjet cutting, typical part tolerances range from between 0.003″ and 0.005″ of an inch.

Can waterjet machine cut glass?

Waterjet machines are highly capable of cutting glass, making it a versatile method for glass fabrication. The process involves utilizing a high-pressure jet of water, often mixed with an abrasive material, to precisely cut through the glass.

When cutting glass with a waterjet machine, certain considerations should be taken into account to ensure optimal results. Firstly, the addition of abrasive material, such as garnet, to the waterjet stream enhances the cutting ability. The abrasive particles aid in eroding the glass, facilitating clean and accurate cuts.

To achieve efficient and precise glass cutting, it is crucial to adjust the cutting parameters appropriately. Factors like water pressure, nozzle size, traverse rate, and abrasive flow rate must be carefully calibrated, taking into account the thickness and type of glass being cut.

Glass is a delicate material, and precautions should be taken during the cutting process to minimize the risk of cracks, chipping, or damage. Proper fixturing and support techniques are often employed to securely hold the glass in place during cutting.

Waterjet cutting is favored for glass cutting due to its ability to produce intricate shapes, sharp corners, and minimal heat-affected zones. Unlike other cutting methods, waterjet cutting generates minimal heat, reducing the likelihood of thermal stress or distortion in the glass.

For specific questions, please contact us, and we will arrange professional service personnel to answer for you.