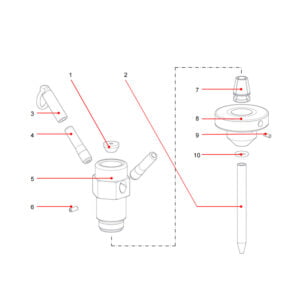

Description

Waterjet cutting parts check valve adapter

Item number: 1003433

| 1027347 | Valve body |

| 1004604 | Check valve assembly |

| 1003551 | Hydraulic piston |

| 1003544 | Hydraulic cylinder |

| 1003644 | Filter Housing |

| 1003433 | Check valve adapter |

| 1004146 | Hydraulic cylinder |

| 1001653 | High pressure seal ring |

| 1009700 | Coupling |

| 1003302 | High pressure filter |

| 1004541 | Check valve repair kit |

| 1004386 | Piston retaining ring |

FAQ of waterjet cutting machine – 12 common waterjet cutting users may encounter faults and solutions:

A waterjet is a high-precision cutting device commonly used for cutting materials in manufacturing. However, long-term use can cause various failures of the waterjet cutting parts. Therefore, it is very important for users to understand the common faults of waterjet cutting parts and their solutions. Here are 25 common waterjet cutting parts failures and their solutions:

- Low water pressure: caused by a bad water pump or a clogged filter. Solution: Replace with a new water pump or clean the filter.

- Loose connections: can cause a drop in pressure. Solution: Check the connection and tighten it.

- Uneven cutting: caused by nozzle wear, too little water flow, or inconsistent distance from the material. Solution: Replace with a new nozzle, adjust the distance, and increase water flow.

- Automatic cutting system failure: caused by data errors or software freezes. Solution: Check data and software, reinstall or update.

- Head wear: excessive use can cause wear or damage. Solution: Replace with a new cutting head.

- Nozzle clogged: blocked by debris. Solution: Remove the nozzle for cleaning or replacement.

- Slow cutting speed: caused by pressure drop or throat blockage. Solution: Replace with a new water pump or clean the throat.

- Controller failure: may lead to failure of the automatic cutting system. Solution: Replace the damaged controller.

- Switch failure: inconvenient operation and cutting stop. Solution: Replace with a new switch.

- Insufficient water flow: caused by an old water pump or a clogged filter. Solution: Replace with a new water pump or clean the filter.

- Leaking water pipes: may cause poor cutting results or the machine may not work properly. Solution: Replace damaged water pipes.

- Loose faucet: poor cutting results. Solution: Check the faucet and fix it

To sum up, the above are 12 possible faults that waterjet cutting parts may encounter and their corresponding solutions. Of course, a better approach is to follow the waterjet cutting parts precautions, such as regularly inspecting and maintaining the waterjet cutting parts, to avoid these failures. When using the waterjet cutting parts, you must strictly follow the instructions in the instruction manual and solve the problem in time when there is a problem.