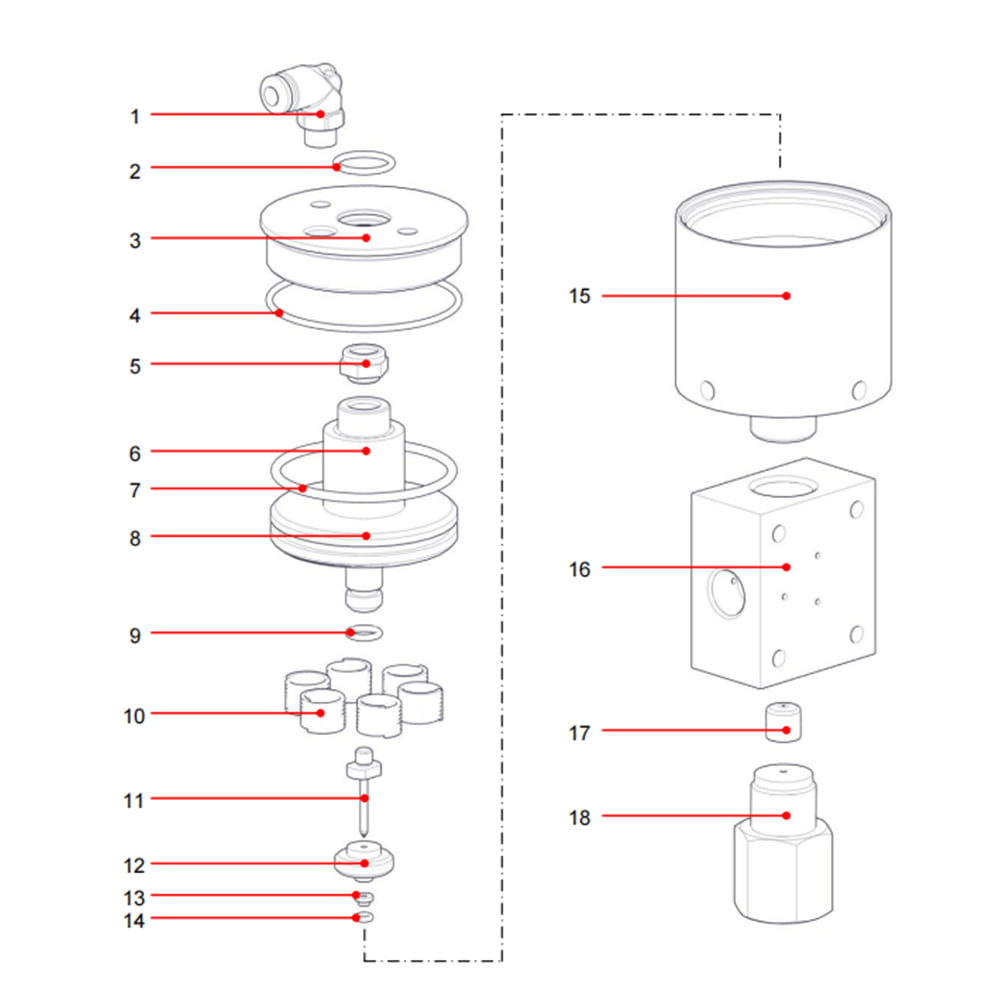

Description

Waterjet cutting parts Air Operated Needle Valve Cutting Head Part

Item number: 1003725

There are some related waterjet cutting parts for the valve assy:

| Item number | Description |

| 1002480 | Push in knee 6 x 1/8″ |

| 1004403 | O-ring |

| 1000801 | Cover |

| 1002838 | O-ring |

| 1000767 | Grate nut |

| 1000804 | Bushing |

| 1004402 | O-ring |

| 1047774 | Piston NO |

| 1002836 | O-ring |

| 1004206 | Spring |

| 1000791 | Needle |

| 1002835 | Seal thrust ring |

| 1002834 | HP seal |

| 1001643 | Cup |

| 1000805 | Valve body |

| 1000796 | Seat |

| 1047750 | Adapter |

Other related waterjet cutting parts:

| 1027347 | Valve body |

| 1004604 | Check valve assembly |

| 1003551 | Hydraulic piston |

| 1003544 | Hydraulic cylinder |

| 1003644 | Filter Housing |

| 1003433 | Check valve adapter |

| 1004146 | Hydraulic cylinder |

| 1001653 | High pressure seal ring |

| 1009700 | Coupling |

| 1003302 | High pressure filter |

| 1004541 | Check valve repair kit |

| 1004386 | Piston retaining ring |

FAQ of waterjet cutting machine & waterjet accessories: How can I extend the life of my waterjet intensifier? Is there any good suggestion?

In order to prolong the service life of the waterjet intensifier, we have the following suggestions for your reference:

All prerequisites: It is important to follow proper maintenance procedures and to use within recommended operating parameters.

- Follow the manufacturer’s maintenance recommendations: including specific maintenance procedures, regular inspection of waterjet cutting parts, lubrication and replacement of worn or damaged parts, etc.

- Use good quality water cutting accessories: the best choice is to use the original accessories of the same brand. In order to save costs, you can also find alternative products, but you must choose a water cutting product supplier with a good reputation, and you must Accurate specific parameters of water cutting accessories; parts such as sealing are very important, once the sealing is not good, it is easy to cause the problem of pressure relief, resulting in insufficient pressure, which will affect the cutting effect and speed.

- Strictly monitor the operating parameters of the machine: For example, the pressure of our common waterjet intensifier pumps is generally within 420MPA. If the working pressure exceeds this maximum value, it may cause damage to related parts; another is the intensifier pump. The temperature of the cutting machine should also be paid attention to at all times. If the temperature is too high, the machine will send out an alarm to stop the cutting work. It is best to operate all the data within the recommended value range to ensure the long-term working condition of the intensifier.

- Training for operating staff: proper operation, installation and maintenance training for staff can enable staff to perform correct maintenance when the machine needs to be maintained, which can reduce the risk of failure and other problems and increase the service life.

Basically, following these tips, you can prolong the service life of the water cutting intensifier. Of course, if you encounter other problems about water cutting, you can also contact us. We have professional maintenance personnel who have been engaged in the water cutting industry for more than 20 years. Professional opinions and suggestions will help you solve the water cutting problems you encounter in time.