Description

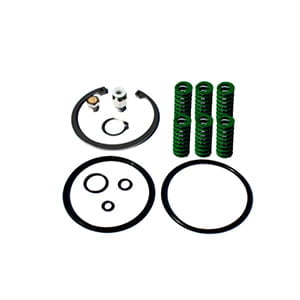

500-20-0158 Clamp Nut Waterjet Consumables

| IMAGE | SKU | NAME | ||

|---|---|---|---|---|

| 5109111 | Autoline Sapphire Orifice 0.011″ | |||

| 05109111 | Autoline Sapphire Orifice 0.011″ | |||

| 20412569 | Autoline Sapphire Orifice 0.013″ | |||

| 5109137 | Autoline Sapphire Orifice 0.014″ | |||

| 05109137 | Autoline Sapphire Orifice 0.014″ | |||

| 10187250N | Backup ring | |||

| 11111 | Blue Thread Goop, 2 OZ | |||

| 10188233N | Brass Backup Ring | |||

| 10188233 | Brass Backup Ring | |||

| 13612 | Button Head Screw | |||

| 500-20-0158 | Clamp Nut | |||

| DD-074 | Coil | |||

| 12276 | Collet | |||

| 500-20-0159 | Collet | |||

| EL-49-2 | Cylinder Body | |||

| SP-49-12 | Cylinder Body | |||

| SP-49-13 | Cylinder Body | |||

| EL-69-2 | Cylinder Liner | |||

| SP4-69-175 | Cylinder Liner | |||

| SP-69-10 | Cylinder Liner | |||

| SP-69-9 | Cylinder Liner | |||

| PTTC-009 | Datum Block | |||

| 500-20-0056 | Diamond Orifice 0.010″ | |||

| 500-20-0057 | Diamond Orifice 0.011″ | |||

| 500-20-0058 | Diamond Orifice 0.012″ |

Knowledge of waterjet cutting machine and Waterjet Consumables:

What type of water and abrasive should I use for cutting?

As for water, you can use tap water, but in order to make the water quality better, so that there are fewer faults in the use of the machine, and the life of high-pressure parts is increased, it is recommended to match a water softening and filtering system.

About abrasives: It depends on the material to be cut, usually 80mesh abrasives are used, if you want to cut the surface of the material smoother, you can choose 120mesh abrasives.

How to troubleshoot the common problems of the machine?

The common problems of water jet machines are generally water leakage, oil leakage and cutting water column divergence, cutting speed drop, etc.

1. Water leakage, usually some seals in the waterway part are worn out, which needs to be checked and replaced in time, such as on/off valve seal, high pressure seal, check valve repair kit, etc.

2. Oil leakage, usually the seals of the oil circuit are worn out, which needs to be checked and replaced in time, such as piston seal, rod seal, etc.

3. The water column diverges and the cutting efficiency is poor: At this time, it is usually necessary to check the nozzle and orifice to see if they are abnormal or worn, and replace them if necessary.

The above parts are Waterjet Consumables, which need to be checked and replaced regularly.

Win-Win is a waterjet cutting machine and waterjet parts supplier, If you want to know Waterjet Consumables waterjet pumps and waterjet cutting machine, contact me please