Description

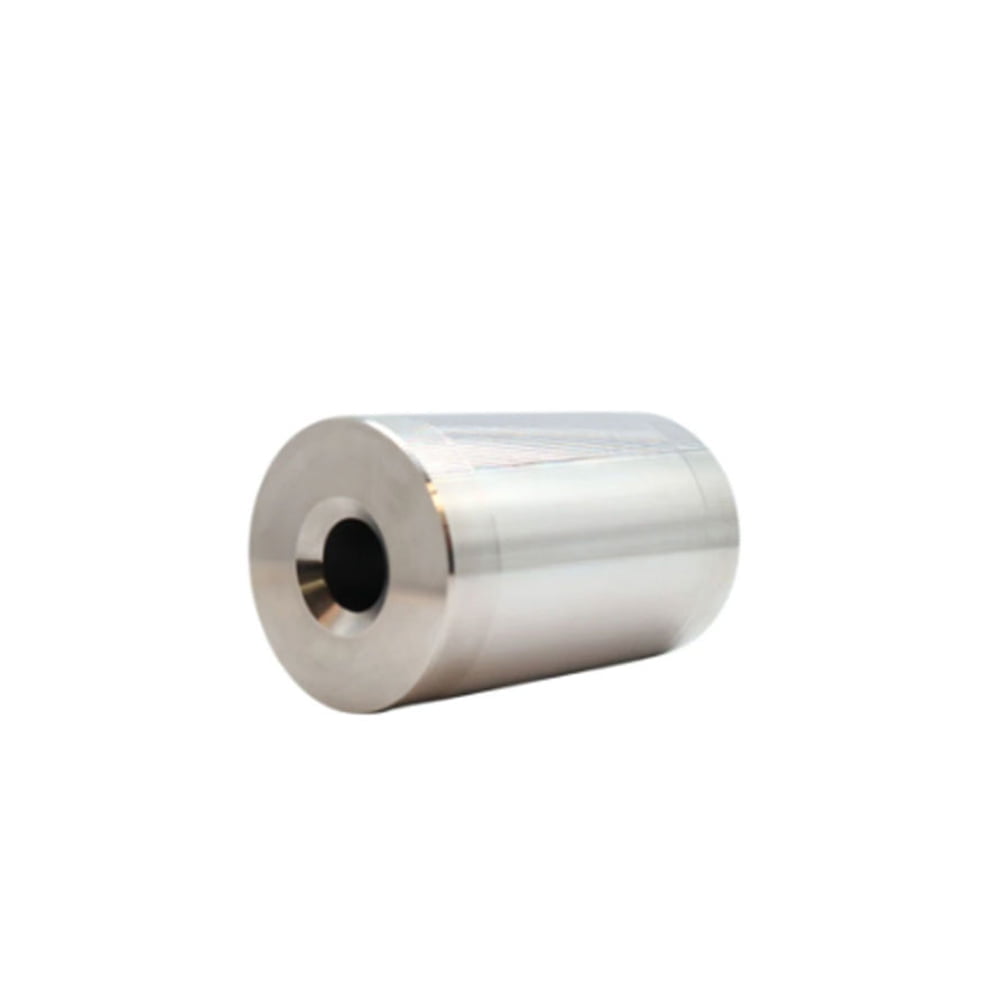

Item number: 020592-1

Item description: water jet factory selling high pressure cylinder withstand 87kpsi

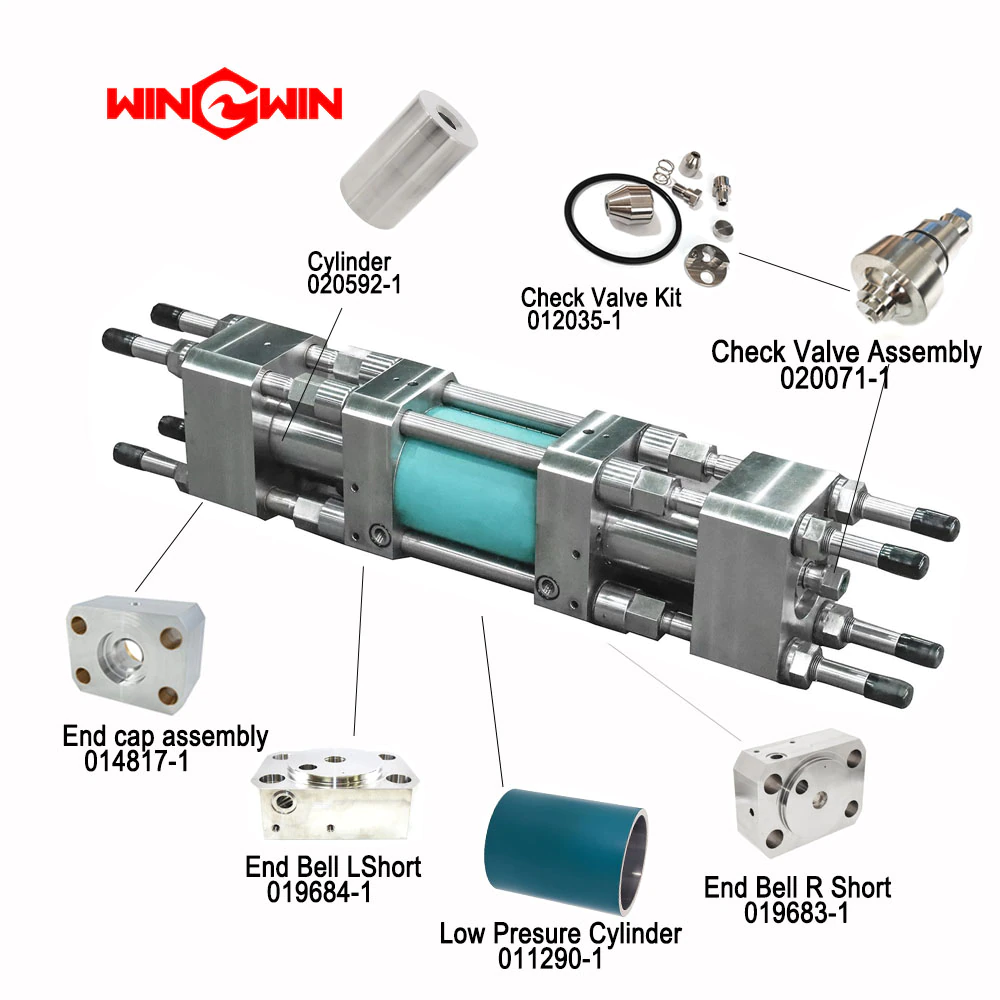

Installation position: as the following photo shows, used on the intensifier pump to connect with end cap

How to determine the quality of 87k high pressure cylinder purchased by customers in water jet factory?

About the quality of water jet cutting machine parts should pay attention to six points:

1: The raw material used by water jet factory is very important. The raw material purchased by WIN-WIN Waterjet Company is the metal material developed by Chinese Research Institute. The commonly used water jet cutting material is H7-14 stainless steel, but it is not the only one. It’s the same as the Chinese brand: 0Cr17Ni4Cu4Nb. Precipitation hardened steel with copper added at 17-4PH. 17-4PH is used in the manufacture of shaft and steam turbine components, and is also used in water cutting accessories. The 17-4PH alloys are precipitated, quenched, martensite stainless steel, and this grade materials has high strength, and hardness & corrosion resistance. After the heat treatment, the mechanical properties of the product will be perfect for the water jet machine, it can reach up to 1100-1300 MPA compressive strength. At this grade of material can not be used above 3000C (572 0F) or very low temperature, it has good corrosion resistance to atmosphere and dilute acid or salt, its corrosion resistance is the same as 304 and 430, water jet factory using this material is not directly processed, After the purchase of raw materials, various processes are needed to meet requirement

2: Water jet cutting parts production process, water jet factory after receiving raw materials, the need for quality inspection of raw materials, first to diagnose whether there are impurities and cracks inside the material, the use of special equipment for internal quality inspection of the material, and then to test the hardness of the material

3: Water jet cutting parts hardness: water jet factory to water jet cutting parts material for heat treatment, after heat treatment to hardness test, hardness can be produced after reaching

4: The production equipment of water jet factory, the use of advanced water jet cutting machine parts production equipment is very important, the use of advanced five-axis CNC machine tool to process the parts, the use of a clamping, directly complete the processing, to ensure the good accuracy of the parts

5: Water jet factory needs to polish water jet cutting machine parts. Water jet parts have very high requirements on the plane, and the polishing surface finish needs to reach level 0.08, to ensure the long-term use of water jet machine parts. Normally the water jet factory with power and influence will have a large inventory of the waterjet spare parts, the purpose is to be able to deliver the waterjet machine spare parts to deliver to customers, reduce the customer equipment production loss