Description

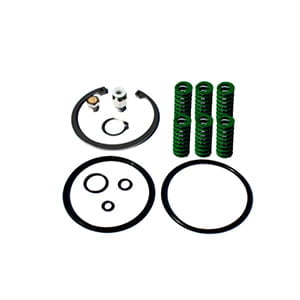

SP1120 Guide Bush Assembly 66K Waterjet Replacement Parts

| IMAGE | SKU | NAME | ||

|---|---|---|---|---|

| 500-20-0059 | Diamond Orifice 0.013″ | |||

| 500-20-0060 | Diamond Orifice 0.014″ | |||

| 5116561 | Discharge Poppet Check Valve | |||

| 05116561 | Discharge Poppet Check Valve | |||

| 12401 | Filter Element | |||

| 10126969 | Focusing Tube 0.030″ | |||

| 500-15-0060 | Focusing Tube 0.030″ (3″) Straight cutting | |||

| 10126928 | Focusing Tube 0.040″ | |||

| 500-15-0070 | Focusing Tube 0.040″ (3″) Straight cutting | |||

| 500-15-0020 | Focusing Tube 0.040″ (PAC – 2.5″) | |||

| 11679-012 | Garnet Tube O-Ring | |||

| 500-3-0061 | Grease, 0.75 OZ | |||

| SP1115 | Guide Bush Assembly | |||

| SP1092 | Guide Bush Assembly 55K | |||

| SP1107 | Guide Bush Assembly 66K | |||

| SP1120 | Guide Bush Assembly 66K | |||

| 10079580 | HP Adaptor (For Square Valve Body Only) | |||

| 500-20-0111 | HP Check Valve Seat | |||

| 11288 | HP Coned Insert | |||

| 500-20-0113 | HP Outlet Poppet | |||

| 500-20-0110 | HP Outlet Poppet Kit – Seat, Poppet & Spring | |||

| SP1052 | HP Seal Assy 66K | |||

| SP1055 | HP Seal Assy 66K | |||

| SP1060 | HP Seal Assy 66K | |||

| 500-20-0112 | HP Spring |

Knowledge of Waterjet Cutting Machine and Waterjet Parts Waterjet Replacement Parts:

Are there any considerations for water jet cutting for cutting metal?

There are the following points:

1, safety protection: we all know that water jet cutting machine is a high-pressure water jet to cut a variety of materials, this high-pressure water since the metal can be so hard materials can be cut, you can imagine how powerful it is, if the staff is not careful in the operation, accidentally put the hand under the high-pressure water will cause what results, so in the machine cutting must pay attention to protect themselves. Do a good job of protective measures.

2, good cleaning and maintenance: all machines in the use of the process need to love it, maintain it, and regularly clean it to avoid wear and tear or clogging.

3, reasonable parameter settings: water jet cutting machine cutting settings and operations are set and adjusted by the CNC system to achieve, for different materials and thicknesses, we need to set the appropriate parameters to achieve optimal cutting efficiency.

4, cutting after processing: water jet cutting machine can only achieve the cutting of the material, can not do grinding, engraving, grinding edge, etc., so if there are some materials need these processes, then you need to use other tools to complete.

Win-Win is a waterjet cutting machine Waterjet Replacement Parts and Waterjet Parts manufacturer, If you want to know anything, contact me please

The following is our products and Waterjet Replacement Parts display.

Win-Win provice Waterjet Replacement Parts nozzle, Waterjet Replacement Parts orifice, Waterjet Replacement Parts cutting head parts, Waterjet Replacement Parts pump parts and other Waterjet Replacement Parts.