Description

A‑11275 water jet part Spring‑Energized Rod Seal

What are the advantages of waterjet cutting?

- it can be cut in a wide range.

It can cut most materials, such as metal, marble, glass, and so on.

- Good cutting quality.

Smooth incisions do not produce rough, burr edges.

- No hot processing.

Because it uses water and abrasive cutting, there is no heat (or very little heat) in the machining process, and this effect is ideal for materials affected by heat. Such as titanium.

- Good environmental protection.

This kind of machine uses water and sand cutting, in the processing process will not produce poison gas, can be discharged directly, more environmentally friendly.

- No need to change the tool.

You do not need to change the cutting machine device, a nozzle can process different types of materials and shapes, saving cost and time.

- Reduce burr.

Using water with abrasive sand to cut, the cut has only a few burrs.

7, combined with other equipment, can be operated separately.

The waterjet cutting machine can be matched with other processing equipment (such as a drilling head) to make full use of its performance and optimize the utilization of materials.

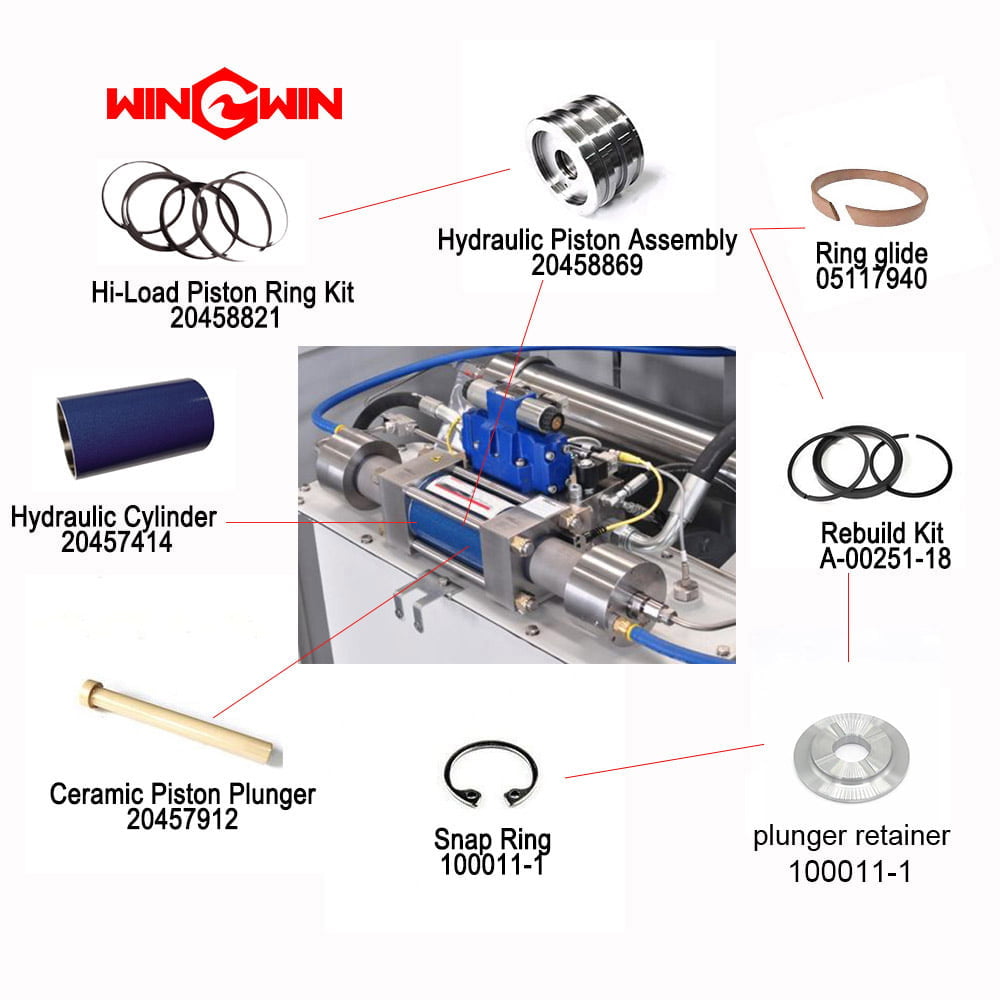

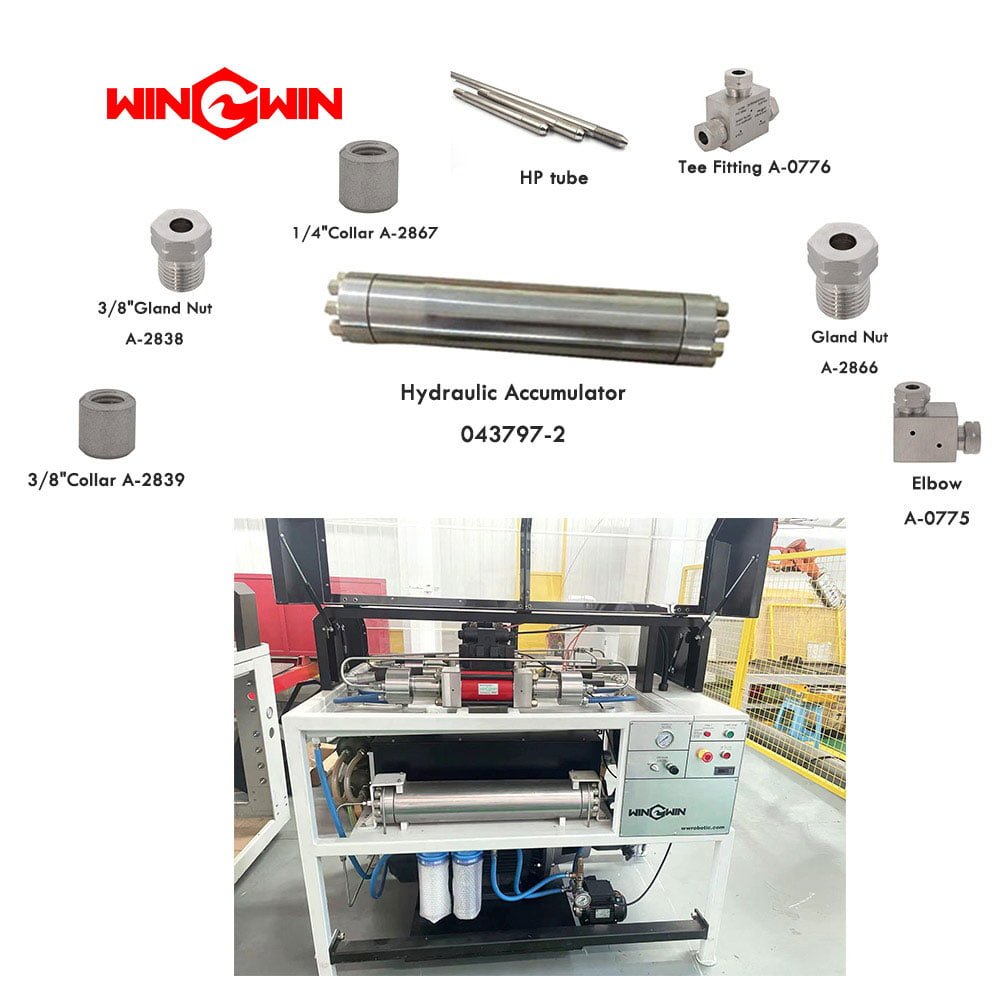

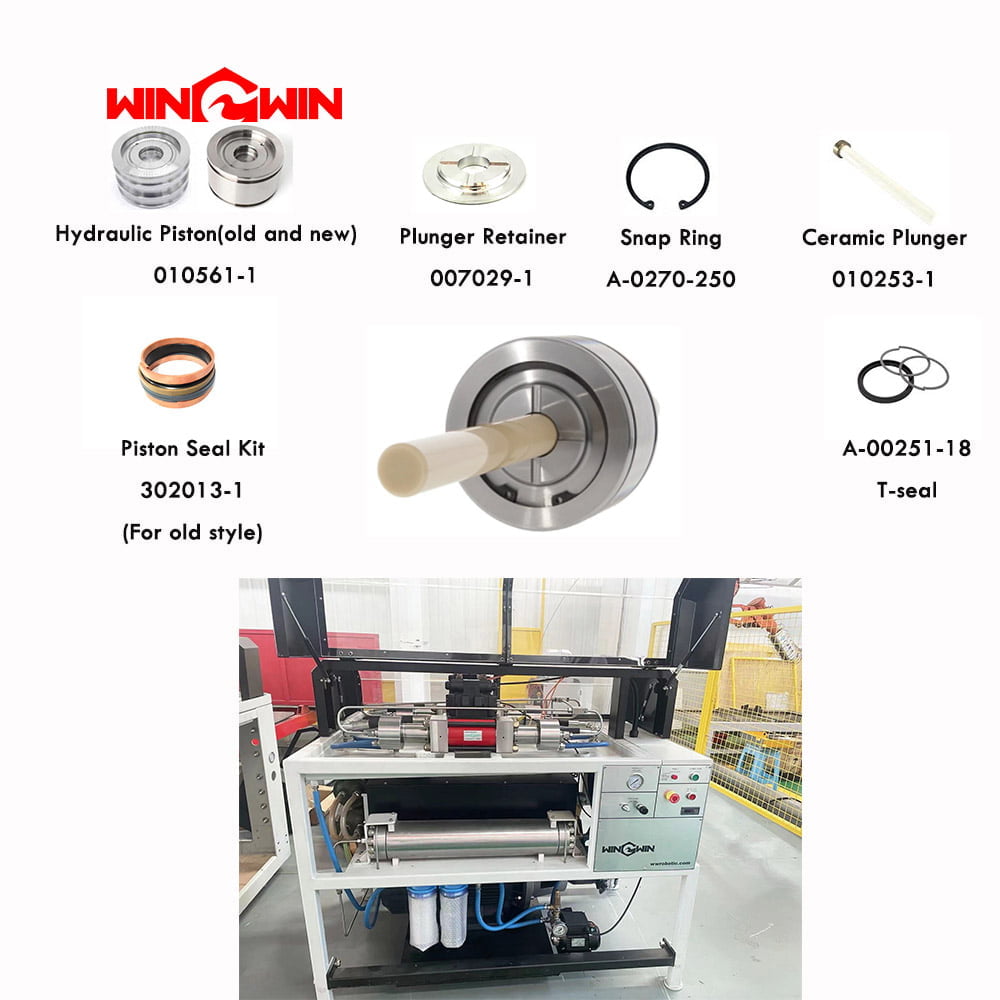

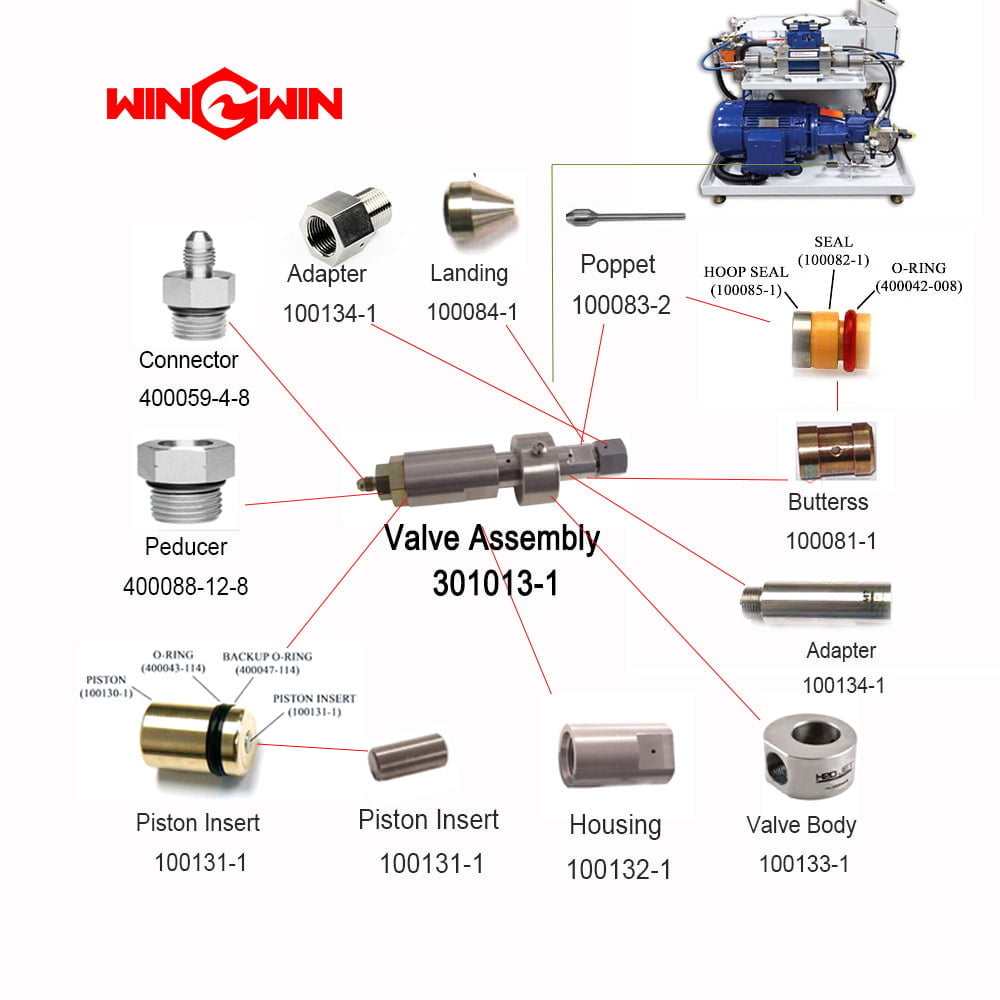

water jet part

- Reduce the number of adjustments.

Only a small side pressure is needed to fix the workpiece, reducing the trouble caused by complex clamping.

- Without the restriction of cutting direction, you can complete a variety of different cutting shapes.

- The drilling and cutting functions can be completed with the same machine, which can reduce the processing time and cut costs.

- No thermal effect or deformation or fine cracks do not need secondary processing, which can save time and manufacturing costs.

- Non-toxic gases can provide a better working environment for operators.

- The fine cut can reduce the production of a large number of waste materials and save direct manufacturing costs.

- water jet part