Description

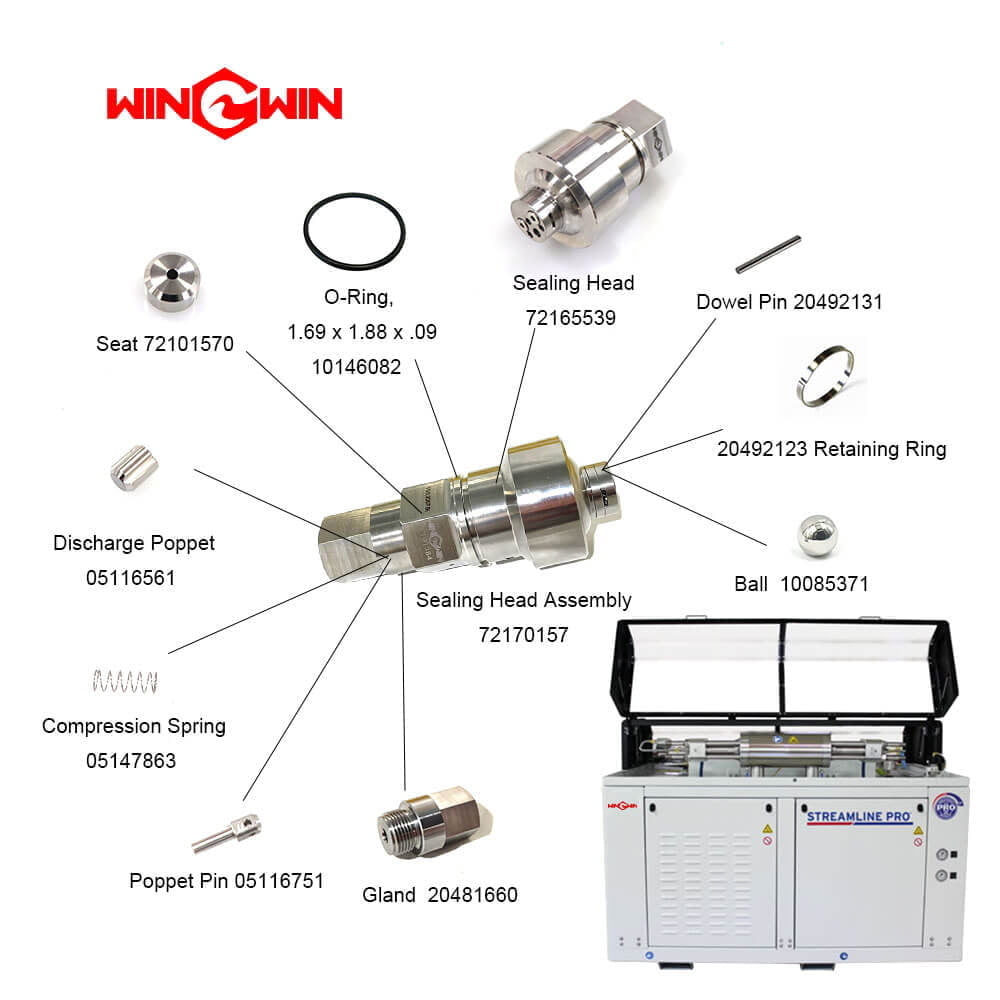

Sealing Head 72165539 is a important spare part of 90K waterjet pump.

Item | Part Number | Description | Quantity | Item | Part Number | Description | Quantity |

1 | 05146592 | Gasket, Topworks Support | 2 | 14 | 72162253 | Plunger | 2 |

2 | 20476377 | Support, Topworks | 2 | 15 | 05130091 | Hydraulic Seal Cartridge | 2 |

3 | 10118206 | O-Ring, 1.31×1.56× .13 | 2 | 16 | 72175989 | Bushing Retainer Flange | 2 |

4 | 05144514 | Hydraulic Cylinder | 1 | 17 | 72158494 | UHP Seal Assembly | 2 |

5 | 05098991 | Socket Head Screw, 3/8-16×3-3/4 | 8 | 18 | 72166738 | UHP Cylinder | 2 |

6 | 95688743 | Lock Washer, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Piston Assembly | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

8 | 10074771 | O-Ring, 5.25×5.50× .13 | 2 | 21 | 72170157 | Sealing Head Assembly | 2 |

9 | 05120092 | Backup Ring, 5.25×5.50× .13 | 2 | 22 | 72178493 | Flange Assembly | 2 |

10 | 72175997 | Hydraulic Cylinder Head | 2 | 23 | 20464590 | Flat Washer, 1.13 | 8 |

11 | 05097886 | Socket Head Screw, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Hex Nut, 1-1/8-12 | 8 |

12 | 05144183 | Spacer Assembly, Proximity Switch | 2 | 25 | 20489339 | Adapter, JIC/Pipe, 50× .38 | 1 |

05144191 | O-Ring, .69× .88× .09 | 26 | 72176756 | O-Ring, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, Proximity Switch | 2 | ||||

| 72134224 | Proximity Switch | ||||||

95119012 | Socket Head Screw, 1/4-20×1 |

The sealing head of a waterjet pump is a critical part that helps to maintain the pressure and flow of water through the pump.

The sealing head is located at the top of the waterjet pump and is responsible for sealing the high-pressure water inside the system, preventing leaks and ensuring that the water is directed to the cutting or cleaning tool.

The sealing head typically consists of several components, including the plunger, the seal, and the check valve. The plunger is a piston-like component that moves up and down to create the high-pressure water stream. The seal is a specialized component that is designed to prevent water from escaping through the top of the waterjet pump.

The check valve is designed to govern the flow of water through the system and preventing backflow.

It is essential that the sealing head is properly maintained and inspected to make sure that it is functioning correctly. Regular maintenance and inspection can help to stem leaks and other issues that can affect the performance and efficiency of the waterjet pump system.

The frequency of inspection for the sealing head of a waterjet pump depends on several factors, including the intensity of use, the operating conditions, and our manufacturer’s recommendations. However, as a general rule, it is recommended to inspect the sealing head at least once a year or after every 1,000 hours of operation, whichever comes first.

During the inspection, you should check the condition of the plunger, seal, and check valve for any signs of wear or damage. You should also inspect the inlet and outlet fittings, pressure gauge, and relief valve to ensure that they are functioning correctly and not leaking.

If any issues or signs of wear are detected during the inspection, it is recommended to replace the affected components as soon as possible to prevent any further damage or potential safety hazards.

However, the frequency of inspection may vary depending on the specific pump model. Therefore, it is always best to consult our manufacturer’s guidelines or seek advice from a qualified technician to determine the appropriate inspection frequency for your specific waterjet pump.

If you have any questions or want to order the products, please contact us.