Description

90,000 PSI Waterjet 20452962 UHP Gland, .25

Introduction

Waterjet cutting has become an essential part of the manufacturing industry due to its precision and efficiency in cutting various materials.

The waterjet nozzle is a critical component that generates a powerful stream of water that can cut through different materials with ease.

The UHP Gland .25 is a vital tool for holding the nozzle in place and maintaining optimal water pressure for precision waterjet cutting PSI and hydrojet cutting.

In the following sections, we will explore the features and benefits of the UHP Gland .25, which is optimized for high pressure waterjet cutting and hydrojet cutter requirements.

We will also delve into the highest and average PSI for waterjet cutting, how deep waterjet can cut, the cost of waterjet cutting, and how accurate waterjet cutting can be.

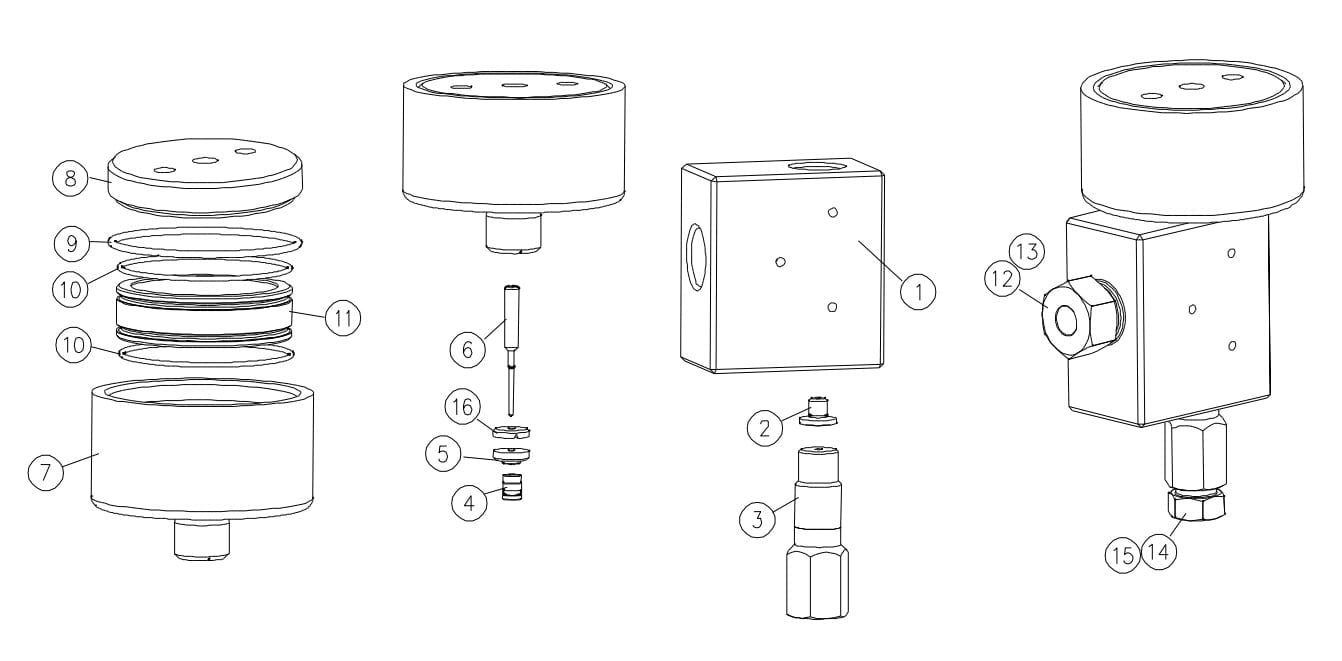

Item | Part Number | Description | Quantity | Item | Part Number | Description | Quantity |

1 | 20468617 | Valve Body | 1 | 9 | 10074714 | O-Ring, 2.44 x 2.63 x .09 | 1 |

2 | 10178697 | Valve Seat | 1 | 10 | 10074565 | O-Ring, 2.25 x 2.38 x .06 | 2 |

3 | 20451557 | UHP Adapter | 1 | 11 | BV501184 | Piston | 1 |

4 | 72112069 | Seal Assembly | 1 | 12 | 20452965 | UHP Collar, .38 | 1 |

5 | 20475874 | Backup Ring, Bronze | 1 | 13 | 20452956 | UHP Gland, .38 | 1 |

6 | 20475878 | Valve Stem | 1 | 14 | 20452959 | UHP Collar, .25 | 1 |

7 | 20468601 | Pneumatic Cylinder | 1 | 15 | 20452962 | UHP Gland, .25 | 1 |

8 | BV601184 | Cylinder Head | 1 | 16 | 20475882 | Backup Ring, SST | 1 |

| 20477518 | Spare Parts Kit | ||||||

| Includes items 2, 4, 5, 6, 9, 10 and 16 |

Features of UHP Gland .25

The UHP Gland .25 is specially designed for high pressure waterjet cutting and hydrojet cutting applications.

It is an essential component of the waterjet system that holds the nozzle in place and maintains optimal water pressure.

It is made from high-quality materials like stainless steel, which is strong and durable.

Its leak-free design ensures that the water pressure is maintained at a consistent level, resulting in precise and clean cuts.

The UHP Gland .25 is fit for several nozzle sizes, making it suitable for different cutting applications.

Its precision machining ensures that it maintains the correct position and alignment even under high-pressure conditions.

Highest and Average PSI for Waterjet Cutting

Water pressure is a crucial factor in waterjet cutting, as it determines the speed and effectiveness of the cutting process.

The highest PSI for waterjet cutting is 90,000 psi (620 MPa), while the average PSI ranges from 15,000 to 40,000 psi (103 to 276 MPa).

Ultra high pressure is between 40,000 psi to 75,000 psi (276 to 517 MPa).

The pressure rating of a waterjet cutting system is measured in PSI and refers to the amount of force that is applied to the water as it passes through the nozzle.

The higher the water pressure, the more forceful the waterjet stream will be, resulting in faster cutting speeds and cleaner cuts.

Depth of Waterjet Cutting

Hydrojet cutters can make cuts of up to 10-12 inches in hard materials.

However, the depth of waterjet cutting depends on the material being cut and the pressure of the waterjet stream.

Thicker materials can be cut, but it reduces the cutting speed.

Cost of Waterjet Cutting

The cost of waterjet cutting varies depending on the hourly rate, which typically ranges from $12 to $30 per hour.

However, the cost can go higher or lower depending on specific requirements such as the complexity of the design, the material being cut, and the thickness of the material.

Waterjet cutting can be a cost-effective solution for businesses as it reduces material waste and increases productivity.

Additionally, the precision and efficiency of hydrojet cutter can result in significant cost savings as time goes on.

Accuracy of Hydrojet Cutter

Hydrojet cutter can produce parts with a high degree of accuracy.

Some systems can create components with a tolerance as close as 0.001″ (0.025 mm).

Typical component tolerances range from between 0.003″ and 0.005″ of an inch.

The accuracy of waterjet cutting depends on the quality of the machine used, the nozzle size, and the material being cut.

Waterjet cutting is a highly precise cutting method that produces clean and accurate cuts without causing heat-affected zones or material distortion.

Benefits of UHP Gland .25 for 90,000 psi Waterjet Cutting

The UHP Gland .25 offers several benefits for 90,000 psi waterjet cutting.

Its high-pressure rating of up to 90,000 PSI makes it a reliable tool for precision cutting requirements.

Its leak-free design guarantees that the water pressure is maintained at a consistent level, resulting in precise and clean cuts.

Its precision machining ensures that it maintains the correct position and alignment, even under high pressure conditions.

By using the UHP Gland .25, hydrojet cutters offer enhanced precision, improved cutting speed, reduced machine downtime, and cost-effectiveness.

The UHP Gland .25 is an essential component that ensures the optimal performance of waterjet cutting systems, and it is a valuable investment for businesses seeking to improve the cutting capabilities.

Applications of Waterjet Cutting

Waterjet cutting is suitable for a wide range of applications.

It can cut through various materials, including metals, plastics, composites, and even food products. 90,000 psi waterjet cutting can be used in the medical, aerospace, automotive, defense industries and so on.

Waterjet cutting is an environmentally friendly and sustainable cutting method that does not produce hazardous waste.

The versatility and precision of waterjet cutting make it the preferred method for cutting complex shapes and designs, and it is an ideal choice for businesses seeking to improve their cutting capabilities.

Conclusion

The UHP Gland .25 is a critical component for precision 90,000 psi waterjet cutting applications.

Its high-pressure rating, robust construction, precision machining, leak-free design, and compatibility with a range of nozzle sizes make it a versatile and durable tool for different cutting applications.

Waterjet cutting offers several benefits over traditional cutting methods, including precision, efficiency, versatility, environmental friendliness, and cost-effectiveness.

By using the UHP Gland .25 in 90,000psi waterjet cutting and hydrojet cutters, businesses can enhance the cutting capabilities, reduce machine downtime, and achieve higher levels of precision and productivity.

With the highest and average PSI range for waterjet cutting, the depth of waterjet cutting, the cost of waterjet cutting, and the accuracy of waterjet cutting covered in this article, businesses can make informed decisions about their cutting requirements.

90,000 psi waterjet cutting is a highly versatile and precise cutting method that can cut through a wide range of materials, making it suitable for various applications.

It is an environmentally friendly and sustainable cutting method that does not produce hazardous waste.

The UHP Gland .25 is a valuable investment for businesses seeking to improve their cutting capabilities and achieve higher levels of precision and productivity.

In conclusion, hydrojet cutter and the UHP Gland .25 are essential tools that can help businesses achieve the cutting requirements.

The UHP Gland .25 is optimized for high pressure waterjet cutting and hydrojet cutter requirements, and its compatibility with different nozzle sizes, precision machining, leak-free design, and durability make it a valuable component for businesses seeking to improve the cutting capabilities.

Any other questions about 90000 psi waterjet products and hydrojet cutters, please contact us.