Description

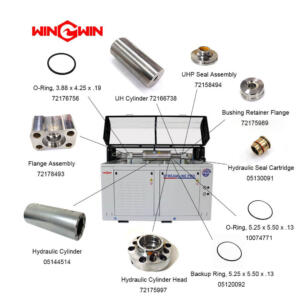

Hydraulic cylinder 05144514 applied to the 90000 psi pump.

A hydraulic cylinder is a mechanical actuator that converts hydraulic energy into linear force and motion.

It consists of a cylindrical barrel, a piston, and a rod, all of which are sealed to prevent fluid leaks.

Hydraulic cylinders are commonly used in hydraulic systems to provide linear motion and force for a wide range of applications.

A hydraulic cylinder can be applied to a 90000 psi pump in a variety of ways, depending on the specific application.

For example, the hydraulic cylinder may be used to provide linear force to actuate a valve or other mechanical component in a 90000 psi pump system.

Alternatively, it may be used to perform a specific task such as lifting or pushing heavy loads in a high-pressure environment.

Item | Part Number | Description | Quantity | Item | Part Number | Description | Quantity |

1 | 05146592 | Gasket, Topworks Support | 2 | 14 | 72162253 | Plunger | 2 |

2 | 20476377 | Support, Topworks | 2 | 15 | 05130091 | Hydraulic Seal Cartridge | 2 |

3 | 10118206 | O-Ring, 1.31×1.56× .13 | 2 | 16 | 72175989 | Bushing Retainer Flange | 2 |

4 | 05144514 | Hydraulic Cylinder | 1 | 17 | 72158494 | UHP Seal Assembly | 2 |

5 | 05098991 | Socket Head Screw, 3/8-16×3-3/4 | 8 | 18 | 72166738 | UHP Cylinder | 2 |

6 | 95688743 | Lock Washer, .38 | 8 | 19 | 72163802 | Liner | 2 |

7 | 72101190 | Piston Assembly | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

8 | 10074771 | O-Ring, 5.25×5.50× .13 | 2 | 21 | 72170157 | Sealing Head Assembly | 2 |

9 | 05120092 | Backup Ring, 5.25×5.50× .13 | 2 | 22 | 72178493 | Flange Assembly | 2 |

10 | 72175997 | Hydraulic Cylinder Head | 2 | 23 | 20464590 | Flat Washer, 1.13 | 8 |

11 | 05097886 | Socket Head Screw, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Hex Nut, 1-1/8-12 | 8 |

12 | 05144183 | Spacer Assembly, Proximity Switch | 2 | 25 | 20489339 | Adapter, JIC/Pipe, 50× .38 | 1 |

05144191 | O-Ring, .69× .88× .09 | 26 | 72176756 | O-Ring, 3.88×4.25× .19 | 6 | ||

13 | 72141569 | Kit, Proximity Switch | 2 | ||||

| 72134224 | Proximity Switch | ||||||

95119012 | Socket Head Screw, 1/4-20×1 |

When selecting a hydraulic cylinder for use with a 90000 psi pump, it’s important to consider several factors.

1. Pressure rating

The pressure rating of the hydraulic cylinder must be compatible with the operating pressure of the 90000 psi pump.

The cylinder must be able to withstand the high pressures generated by the pump without failure or leakage.

2. Materials

The materials used in the construction of the hydraulic cylinder must be able to withstand the high pressures and temperatures generated by the 90000 psi pump.

Common materials used for high-pressure hydraulic cylinders include steel, stainless steel, and aluminum.

3. Mounting options

Hydraulic cylinders can be mounted in a variety of ways, including end mounting, flange mounting, and trunnion mounting.

The choice of mounting option will depend on the specific requirements of the application.

When selecting a hydraulic cylinder for use with a 90000 psi pump, it’s important to work with us to help you select the right cylinder for your specific application.

We can help you consider factors such as load capacity, stroke length, pressure rating, materials, and mounting options to ensure that the hydraulic cylinder is properly matched to the 90000 psi pump and its intended use.

What are some signs that a cylinder in the 90000 psi pump needs to be replaced?

1. Leakage

If you notice fluid leakage around the cylinder or at the rod or piston seals, it may be a sign that the cylinder needs to be replaced.

Leakage can be caused by worn or damaged seals, which can allow fluid to escape from the cylinder.

Fluid leakage can also be caused by cracks or other damage to the cylinder body, which can compromise the integrity of the cylinder.

2. Excessive wear or damage

If the cylinder shows signs of excessive wear or damage, such as cracks, dents, or corrosion, it may need to be replaced.

Damaged cylinders can be dangerous and can cause other components of the 90000 psi pump to fail.

3. Reduced performance

If you notice that the cylinder is not performing as well as it used to, such as slower or weaker movement, it may be a sign that the cylinder needs to be replaced.

Reduced performance can be caused by worn or damaged components within the cylinder, such as seals, bearings, or pistons.

4. Noisy operation

Unusual noises during operation, such as grinding or squeaking, can be a sign of wear or damage within the cylinder.

Noisy operation can be caused by worn or damaged components, or by misalignment of the cylinder within the hydraulic system of 90000 psi pump.

5. Excessive heat

If the cylinder is generating excessive heat during use, it may be a sign of internal damage or wear.

Excessive heat can cause damage to the cylinder and other components of the 90000 psi pump.

6. Safety concerns

If the cylinder is showing signs of wear or damage that could pose a safety risk, such as cracks or leaks, it should be replaced immediately to ensure the safety of personnel and equipment.

Replacing a damaged or worn hydraulic cylinder can help prevent further damage to the 90000 psi pump and ensure safe and reliable operation.

In general, it’s important to regularly inspect hydraulic cylinders for signs of wear or damage, as well as to follow recommended maintenance procedures to prolong their service life.

If you notice any of the signs listed above, it’s important to have the hydraulic cylinder inspected by a qualified technician to determine if it needs to be replaced.

What are some common causes of damage to hydraulic cylinders?

1. Overloading

Overloading is a common cause of damage to hydraulic cylinders.

When a hydraulic cylinder is subjected to a load that exceeds its rated capacity, it can cause damage to the cylinder body, seals, and other components of the 90000 psi pump.

Overloading can occur due to improper selection of the cylinder for the application, or due to changes in the operating conditions of the 90000 psi pump.

2. Side loading

Side loading occurs when a hydraulic cylinder is subjected to forces that are not aligned with its axis of movement.

Side loading can cause damage to the cylinder body, piston, and seals.

Side loading can occur due to improper alignment of the cylinder within the 90000 psi pump, or due to external forces acting on the load being moved by the cylinder.

3. Contamination

Contamination of the hydraulic fluid can be a major cause of damage to hydraulic cylinders.

Contaminants such as dirt, debris, and water can cause damage to the cylinder body and seals, and can cause the 90000 psi pump to operate less efficiently.

Contamination can occur due to improper maintenance of the hydraulic system, or due to external factors such as exposure to dirt or moisture.

4. Corrosion

Corrosion can occur when the hydraulic cylinder is exposed to moisture or corrosive substances.

Corrosion can cause damage to the cylinder body and seals, and can compromise the structural integrity of the cylinder.

Corrosion can occur due to exposure to harsh operating environments, or due to improper maintenance of the 90000 psi pump.

5. Misalignment

Misalignment of the hydraulic cylinder can cause damage to the cylinder body, piston, and seals.

Proper alignment is critical to ensure smooth and reliable operation of the cylinder.

Misalignment can occur due to improper installation or maintenance of the 90000 psi pump, or due to external factors such as uneven ground or loads.

6. Improper maintenance

Improper maintenance can also be a cause of damage to hydraulic cylinders.

Failure to perform regular inspections, lubrication, and other maintenance procedures can cause damage to the cylinder and other components of the 90000 psi pump.

Improper maintenance can also cause contamination of the hydraulic fluid and other issues that can lead to cylinder damage.

By understanding the common causes of damage to hydraulic cylinders, you can take steps to prevent damage and prolong the service life of your 90000 psi pump.

Regular inspections, proper maintenance, and careful operation of the hydraulic system can all help prevent damage and ensure safe and reliable operation.

Any other problems on 90000 psi pump, please contact us.